Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

It is the Tie Rod Ends that provides your car a ability to stay straight, steady and safe which is why you should check them to catch if there’s any hidden steering problems.

Without a doubt, Tie Rod Ends directly affects how your vehicle steers, handles and keeps its tires truly aligned.

So basically, they act as the link between your steering system and the front wheels, which actually allows the tires to turn smoothly whenever you move the steering wheel.

And in most of the vehicles, the tie rod ends are made of a ball-and-socket design that truly allows flexible movement and still keeps the steering system tight and fully responsive.

But just like other components, because of the constant movement, road vibration and exposure to dirt, water and road salt actually causes these joints to wear out in faster way.

Not only this, when tie rod ends wear down, then they literally creates looseness in the steering linkage, which actually make your car pull to one side, vibrate or feel actually unstable at the higher speeds.

So, you should know How to Check Tie Rod Ends, so that you can inspect it timely and replace the worn out tie rod ends to improve the handling and also that extends the lifespan of your tires, ball joints and suspension system as well.

What are Tie Rod Ends?

Tie rod ends are small but crucial components of a car’s steering system.

They are designed to connect the steering rack to the steering knuckle, allowing the front wheels to easily turn left or right whenever you rotate the steering wheel.

The main function of a tie rod end is to transmit direct movement and force from the steering rack to the wheels, ensuring your car goes in the direction you intend.

They play a vital role in keeping your steering stable, your tires properly aligned and your vehicle easy to control.

Without properly functioning tie rod ends, the steering system can become loose or inaccurate, making driving unsafe.

1. Definition and Function in the Steering System

A tie rod end is a flexible joint, typically made with a ball-and-socket design, that allows for movement while keeping the steering system tightly connected.

When you turn the steering wheel, the motion travels from the steering column to the steering rack or steering gearbox.

From there, the tie rods push or pull the steering knuckles, which turn the wheels in the desired direction.

Because tie rod ends are located between the stationary and rotating parts of the suspension, they have to handle both rotational and linear movement simultaneously.

Over time, this constant movement causes the joint to wear out.

Worn tie rod ends can lead to poor alignment, uneven tire wear, steering noise and reduced control over the vehicle.

2. Difference Between Inner and Outer Tie Rod Ends

A steering system typically has two types of tie rods on each side of the vehicle – inner tie rod ends and outer tie rod ends.

The inner tie rod end connects directly to the steering rack and is located closer to the center of the car.

It is protected by a rubber boot that keeps out dirt and moisture.

The outer tie rod end connects to the steering knuckle, which is attached to the wheel assembly.

This outer part allows the wheels to pivot and respond to steering inputs.

The outer tie rod end is also adjustable, which helps in setting the correct wheel alignment or toe angle of the front wheels.

Both parts work together – the inner tie rod transmits movement from the steering rack and the outer tie rod rotates the wheels accordingly.

3. How They Connect to the Steering Rack and Steering Knuckle

The connection between the tie rod ends, the steering rack and the steering knuckle is crucial for smooth and responsive steering.

The inner tie rod end is bolted or screwed into the steering rack, allowing it to move back and forth as the rack moves.

The outer tie rod end is connected to the steering knuckle via a ball stud and castle nut, which securely holds it in place while also allowing for rotational movement.

When you turn the steering wheel, the rack pushes one tie rod while pulling the other, causing both wheels to turn in the same direction.

This mechanism ensures that your car responds correctly to every movement of the steering wheel.

Any looseness or play in these connections can lead to steering problems, vibrations and uneven tire wear.

Maintaining these joints in good condition is essential for safe driving and reliable handling.

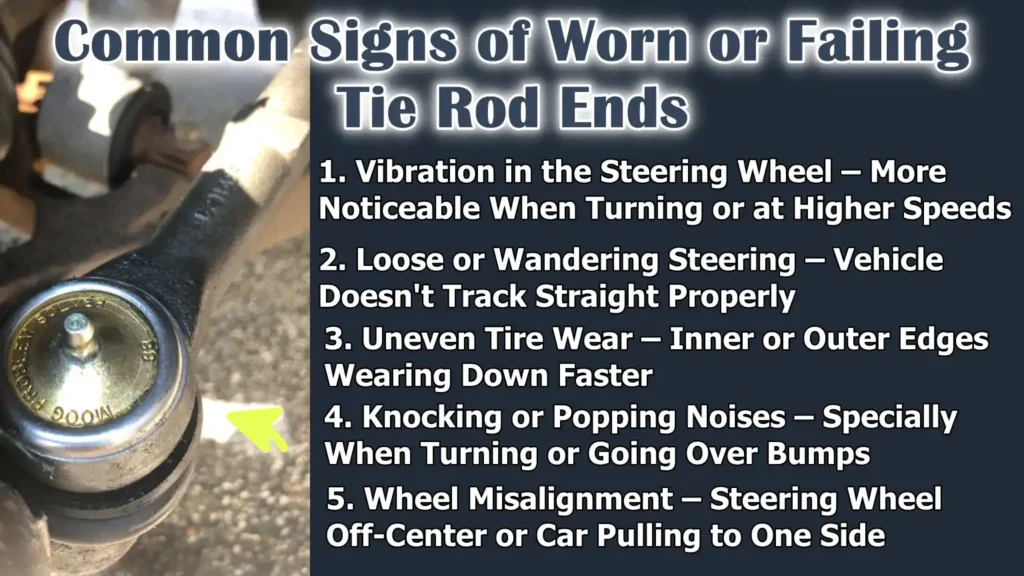

Common Signs of Worn or Failing Tie Rod Ends

Recognizing the signs of worn or failing tie rod ends is crucial because these small parts directly impact your car’s steering, handling and overall safety.

When tie rod ends begin to fail, you may notice changes in your vehicle’s steering or the way your tires wear over time.

Ignoring these warning signs can lead to serious steering problems, uneven tire wear and in some cases, complete steering failure.

Below are some of the most common and easily identifiable symptoms that indicate your tie rod ends are worn or failing.

1. Vibration in the Steering Wheel – More Noticeable When Turning or at Higher Speeds

One of the early signs of worn tie rod ends is a vibration in the steering wheel, specially when turning or driving at higher speeds.

This vibration occurs because the connection between the steering system and the wheel becomes loose.

Instead of moving smoothly, the loose tie rod end allows the wheel to wobble slightly when turning.

This vibration may be subtle at first but often worsens over time.

If left unaddressed, this looseness can lead to poor handling and increased wear on other steering and suspension components.

2. Loose or Wandering Steering – Vehicle Doesn’t Track Straight Properly

When tie rod ends wear out, the steering system loses its tightness and precision.

You may notice that your car no longer tracks straight easily and tends to wander or drift even on a flat road.

This happens because the worn joint allows for free play in the steering linkage, meaning your steering inputs are not fully transferred to the wheels.

As a result, the vehicle feels unstable, specially at higher speeds or when driving on uneven surfaces.

A loose steering wheel is not only inconvenient but also unsafe, as it can compromise your ability to maintain full control of the vehicle.

3. Uneven Tire Wear – Inner or Outer Edges Wearing Down Faster

Uneven tire wear is a sure sign that the tie rod ends are worn out or misaligned.

When these parts become loose, they can cause the wheels to tilt slightly inward or outward, changing the angle of contact between the tire and the road.

This misalignment causes the inner or outer edges of the tires to wear down faster than the rest of the tread.

Over time, this not only reduces tire life but also affects the car’s stability and braking performance.

Regularly checking your tire wear patterns can help you detect tie rod problems early, before they lead to costly replacements.

4. Knocking or Popping Noises – Specially When Turning or Going Over Bumps

If you hear knocking, clunking, or popping noises coming from the front of your car when turning the steering wheel or driving over bumps, it could be an indication that the tie rod ends are loose or worn.

This noise occurs when the ball-and-socket joint inside the tie rod end becomes loose, causing the metal parts to knock against each other.

These noises are often more noticeable at low speeds or when driving on uneven roads.

Over time, the looseness in the joint can worsen, leading to complete failure and the steering system being unable to properly control the wheels.

5. Wheel Misalignment – Steering Wheel Off-Center or Car Pulling to One Side

Worn tie rod ends can also cause your wheels to become misaligned, resulting in the steering wheel being off-center or the car pulling to one side.

Because tie rod ends are directly involved in adjusting the toe angle of the wheels, any looseness or wear immediately affects the alignment.

You might notice the car isn’t driving straight after hitting a pothole or curb.

Continuing to drive with misaligned wheels can lead to excessive tire wear, poor fuel efficiency and increased stress on other suspension components.

Getting an alignment check and having the tie rod ends inspected promptly can prevent these problems and restore smooth, straight steering.

Tools

| Tool or Equipment | Simple Description | How It Helps When Checking Tie Rod Ends |

|---|---|---|

| Floor Jack | A strong lifting device used to lift a car off the ground. | Helps to safely lift the front of the vehicle so you can access and inspect the tie rod ends located underneath. |

| Jack Stands | Metal stands that securely hold the car after it has been lifted. | When working underneath, keep the car stable and prevent it from falling. Never rely solely on the jack. |

| Lug Wrench | A cross-shaped or socket-style wrench used to loosen and tighten wheel nuts. | This allows you to remove the front wheels so you can easily see and access the tie rod ends. |

| Pry Bar or Large Screwdriver | A long, strong metal rod or tool with a flattened end for digging or applying pressure. | It is used to gently move the tie rod end during inspection or to test for looseness, stretch or movement. |

| Flashlight | A small handheld or head-mountable light that helps you see clearly in dark areas. | It provides bright light so you can closely examine the rubber boots, metal joints and connections around the tie rod ends. |

| Assistant or Helper (Optional) | Have another person help you turn the steering wheel or shake the tires while you inspect. | To make the test easier, one person is allowed to move the steering while the other person watches for looseness or movement in the tie rod end. |

| Safety Gloves and Eye Protection | Use protective gloves and clear safety glasses while working. | When inspecting under the vehicle, protect your hands from dirt, sharp edges and grease and protect your eyes from debris or falling dust. |

How to Check Tie Rod Ends – Full Method

Checking your tie rod ends is a simple yet crucial part of ensuring your vehicle’s steering operates safely and correctly.

This process involves carefully lifting the vehicle, inspecting the tie rod ends and checking for looseness or wear.

To begin, park your car on a level surface and ensure the parking brake is firmly engaged.

Before lifting the car, slightly loosen the lug nuts on the front wheels so they can be easily removed after the vehicle is lifted.

Use a floor jack to lift the front of the car and then securely place jack stands under the frame to support it.

This step is essential for safety, as you should never rely solely on the jack while working under the vehicle.

Once the car is stable, completely remove the front wheels to gain access to the steering and suspension components.

First, Park and Secure the Vehicle

1. Choosing the Right Surface

Before beginning any inspection or repair work, ensure your car is parked on a flat, solid surface.

A level driveway or garage floor is ideal as it keeps the vehicle stable while you work.

Avoid parking on soft ground, gravel, or sloped surfaces as this can cause the car to shift or roll while you’re working on it.

A flat surface provides a stable base for lifting equipment such as floor jacks and jack stands, reducing the risk of accidents during the inspection.

2. Engaging the Parking Brake

Once the vehicle is properly parked, firmly engage the parking brake.

This locks the rear wheels and prevents any unwanted movement when you lift the front of the car.

For added safety, you can also place wheel chocks or heavy wooden blocks behind the rear tires.

These simple safety measures help keep the car securely in place and ensure it remains stable throughout the inspection process.

3. Loosening the Lug Nuts Before Lifting

Before lifting the front of the vehicle, use a lug wrench to slightly loosen the lug nuts on both front wheels.

This is a crucial step because it’s easier and safer to loosen the nuts when the tires are on the ground and stable.

Once the vehicle is lifted, applying pressure to remove tight lug nuts can cause movement or instability, which can be dangerous.

At this stage, you only need to slightly loosen the nuts – do not remove them completely yet.

4. The Importance of Proper Parking and Securing

Taking the time to properly park and secure your vehicle is the foundation of safe and effective car maintenance.

It ensures your car remains stable while inspecting the tie rod ends and prevents dangerous situations caused by the vehicle shifting or moving.

Many people overlook this simple step, but it’s one of the most crucial parts of working safely under a vehicle.

Proper preparation not only keeps you safe but also helps you complete the inspection easily and confidently.

How to Lift the Front End

1. Using a Floor Jack to Lift the Vehicle

Once the car is safely parked, the next step is to lift the front end so you can clearly see the steering and suspension components.

A floor jack is the best tool for this job as it provides strong and stable lifting power.

Before placing the jack, locate the correct lifting points under your vehicle.

These points are usually strong areas along the frame or near the front wheels and they are typically marked in most owner’s manuals.

Placing the jack in the correct location is crucial, as lifting from a weak or incorrect point can damage the car’s frame or cause it to slip.

Once the jack is in place, slowly raise the front of the car until the tires are completely off the ground.

Ensure that both sides are lifted evenly and stop immediately if you notice any wobbling or tilting.

2. Securely Placing Jack Stands Under the Frame

After lifting the car, never rely solely on the floor jack to hold it.

The jack is only designed for lifting, not for prolonged support.

For safety, place sturdy jack stands under the car’s frame or at the same lifting points used by the jack.

Adjust the height of the stands evenly on both sides, ensuring they are set at the same level so the car remains balanced.

Once the stands are in place, slowly lower the car onto them by releasing the pressure on the jack.

Ensure that the entire weight of the vehicle is resting on the jack stands and that they are standing upright on the ground without tilting.

Gently shake the car from the side to confirm that it is stable before working underneath.

3. The Importance of Proper Lifting and Support

Properly lifting the front end is one of the most crucial safety steps when inspecting the tie rod ends.

Working under a car supported only by a jack is extremely dangerous because the jack can fail or lose pressure at any time.

Using jack stands provides sturdy support and eliminates the risk of the vehicle falling while you are inspecting or working on steering components.

Always double-check that the ground surface is firm, the stands are secure and the vehicle is stable before proceeding.

Taking a few extra minutes to properly lift and support your car ensures that the inspection process is not only effective but also completely safe.

How to Perform a Visual Inspection

1. Checking the Condition of the Rubber Boots and Grease

After safely lifting and supporting the front of the vehicle, the first step of the visual inspection is to carefully examine the tie rod ends and their protective rubber boots.

These rubber boots are small covers that seal in the grease and prevent dirt, water and debris from entering.

Their job is to ensure that the metal parts inside the joint remain clean and lubricated for smooth movement.

If a rubber boot is torn, cracked, or missing, the grease will leak out and contaminants such as dust or moisture can get in.

This contamination increases friction inside the joint, leading to premature wear and corrosion.

A dry or damaged boot usually means the tie rod end has already begun to wear and may soon become loose or noisy.

It’s important to check both sides of the vehicle, as one tie rod end may wear faster than the other depending on driving habits and road conditions.

2. Checking for Rust, Loose Nuts and Bent Components

Next, carefully inspect the metal parts of the tie rod ends and surrounding suspension components.

Look for clear signs of rust, corrosion, or pitting on the metal surfaces, as these can weaken the tie rod and reduce its ability to maintain alignment.

Rust often occurs when the grease leaks out or when the protective coating wears away due to age or exposure to road salt.

Pay particular attention to the mounting points where the tie rod end connects to the steering knuckle and the adjustment sleeve threads.

Loose or corroded nuts at these locations can cause alignment changes or steering vibrations.

Bent or damaged components are another clear warning sign of damage.

Hitting potholes, curbs, or debris at high speeds can cause tie rods or related components to bend slightly, affecting steering accuracy and tire wear.

Any visible bend or deformation means the part should be replaced immediately.

Even a slight bend can alter wheel alignment and cause the vehicle to pull to one side.

3. The Importance of Careful Visual Inspection

Before performing any movement tests, a thorough visual inspection provides valuable information about the health of your steering system.

It helps identify early signs of wear, damage, or poor lubrication, which if ignored, can lead to more serious steering problems.

This step also helps you determine whether the problem is due to external damage or normal wear and tear over time.

Taking the time to carefully examine the condition of the rubber boots, nuts and metal surfaces will help you determine whether the tie rod ends can be cleaned and lubricated or if they need to be replaced entirely.

Regular visual checks are one of the easiest and most effective ways to maintain safe and responsive steering and extend the life of your suspension components.

How to Check for Play – Movement Test

1. Understanding the Movement Test

The movement test, often called the “play test,” is the most reliable way to determine if the tie rod ends are still tight and functioning properly.

Tie rod ends are responsible for keeping the steering linkage strong and responsive.

When they begin to wear out, the connection between the steering rack and the wheel loosens, causing unwanted movement or “play” in the system.

This looseness directly impacts steering accuracy, tire wear and overall vehicle safety.

By checking for play, you can quickly determine if the tie rod ends are securely attached or if they are beginning to wear from the inside.

This test does not require any special tools and can be easily performed after raising the front wheels off the ground.

2. How to Perform a Movement Test Correctly

To perform a movement test, stand in front of the vehicle and firmly grasp one front tire with both hands, placing your hands at the three and nine o’clock positions on the sidewall.

With steady, controlled movement, slowly rock the wheel back and forth, as if trying to turn it slightly left and right.

Observe how the wheel responds to your movements and pay attention to what you feel with your hands.

The wheel should move slightly as part of normal steering system operation, but the movement should feel firm and tight.

A properly functioning tie rod end will not allow for any excessive looseness or delayed response.

3. Identifying Normal and Abnormal Movement

During this test, slight movement is normal as steering components naturally twist and move slightly.

However, if you notice the wheel turning freely or making a rattling sound, it means the tie rod end is worn.

Excessive play or looseness indicates that wear in the ball joint inside the tie rod has caused excessive clearance, causing the wheel to move away from the steering linkage.

You may also hear a knocking sound or see the tie rod move away from the steering knuckle.

This separation is a clear sign of a malfunction and the tie rod end should be replaced immediately to prevent further damage or unsafe driving conditions.

4. Why the Play Test is So Important

Checking for play is a simple yet effective way to quickly identify steering and suspension problems.

It helps determine whether vibration, uneven tire wear, or loose steering is caused by worn tie rod ends or other components like ball joints or control arms.

Early detection of wear in tie rods allows you to replace parts before serious alignment problems occur or your ability to safely steer is compromised.

Performing this test regularly, specially during tire rotations or oil changes, ensures that your steering system remains stable, precise and reliable on every drive.

How to Observe Tie Rod Movement

1. Understanding the Purpose of the Observation

Observing tie rod movement is a crucial step in diagnosing the condition of your steering components.

If looseness was detected in the previous movement test, observing what’s happening at the tie rod ends can help pinpoint the exact problem.

The tie rod end acts as a pivot point connecting the steering knuckle to the steering linkage.

When it’s functioning correctly, the entire assembly—wheel, tie rod and steering knuckle—moves smoothly together as a solid unit.

Carefully observing this movement while rocking the wheel will reveal whether the tie rod end is still functioning properly or has begun to fail internally.

2. How to Properly Observe the Movement

As you continue to rock the wheel from side to side, focus your attention on the outer tie rod end where it connects to the steering knuckle.

It’s best to have someone assist you—one person can rock the wheel while the other carefully observes the tie rod.

If you prefer to do it alone, use a flashlight to clearly see the joint area.

Under normal conditions, the tie rod end and steering knuckle should move together without any delay or separation.

The ball joint inside the tie rod end should allow for smooth rotation but remain tight and stable within its housing.

3. Identifying Signs of a Failing Tie Rod End

If you observe the tie rod end moving separately from the steering knuckle or there is noticeable looseness within the joint, it’s a clear indication of wear or damage.

The ball-and-socket design inside the tie rod end may have worn down, creating a gap that allows for excessive movement.

In some cases, you may also see grease leaking or a torn rubber boot, allowing dirt and moisture to enter the joint.

These signs indicate that the tie rod end is no longer providing a secure connection and needs to be replaced as soon as possible.

Ignoring this problem can lead to unstable steering, uneven tire wear and even loss of control at higher speeds.

4. Why Visual Inspection is Important

A careful visual inspection of the tie rod movement not only helps confirm the results of the movement test but also gives you a better understanding of the overall steering health of your vehicle.

Many drivers skip this step and replace parts based on guesswork, but directly observing the tie rod’s behavior provides concrete evidence of its condition.

Regularly checking the tie rod ends during maintenance can help prevent steering failure, ensure proper wheel alignment and keep your driving experience safe and reliable.

How to Use the Pry Bar Test – Optional

1. Understanding the Pry Bar Test

The pry bar test is another way to confirm if the tie rod end is loose or worn internally.

While the previous movement and observation tests primarily rely on feel and sight, the pry bar test applies slight mechanical pressure to detect even the slightest looseness hidden within the joint.

This method is specially helpful when the looseness is so minimal that it’s not detectable by simply wiggling the wheel.

Because tie rod ends are responsible for transmitting steering forces from the rack to the wheels, even a small amount of internal looseness can lead to poor handling or premature tire wear.

The pry bar test gives you a more accurate assessment of how tight and stable the connection actually is.

2. How to Perform the Pry Bar Test Safely

To perform this test, with the wheel lifted off the ground, place a sturdy pry bar or large screwdriver between the tie rod end and the steering knuckle.

Apply gentle pressure – just enough to slightly move the parts, without forcing or bending anything.

The goal is not to separate the components, but to observe if there is any unwanted movement in the joint.

Observe carefully while applying pressure.

If the tie rod end is in good condition, the joint will remain firm and there will be no movement between the tie rod stud and its housing.

However, if the joint moves, wobbles, or makes a slight clicking sound, it indicates that the internal ball joint has become loose due to wear.

This wear allows the internal ball to move freely within its socket, which is a clear indication that the tie rod end needs to be replaced.

3. What the Results Indicate

Any movement observed or heard during this test indicates that the internal components have lost their original tightness.

This can happen over time due to the grease drying out, dirt entering through a torn boot, or the constant steering vibrations wearing down the internal ball surface.

Once looseness develops in the tie rod end, it can no longer maintain proper steering precision.

If ignored, this looseness will rapidly increase, eventually affecting wheel alignment and tire stability.

Performing the pry bar test early helps detect this problem before it becomes a safety hazard.

4. The Importance of Careful Testing

The pry bar test should always be performed carefully and with the correct amount of pressure.

Using excessive force can damage the joint or surrounding components.

It’s also crucial to perform this test on both sides of the vehicle, as tie rod wear is rarely uniform.

By incorporating the pry bar test into your inspection routine, you gain a better understanding of your steering system’s health and can determine if replacement is necessary.

This small extra step ensures that your vehicle continues to steer accurately, safely and smoothly.

How to Inspect Both Inner and Outer Tie Rod Ends

1. Understanding the Difference Between Inner and Outer Tie Rod Ends

Most vehicles have a tie rod assembly consisting of two main parts – the inner and outer tie rod ends.

The outer tie rod end connects directly to the steering knuckle, while the inner tie rod end connects to the steering rack or steering gearbox within the vehicle’s front suspension system.

Together, these two components accurately transmit the driver’s steering input to the wheels.

The inner tie rod is responsible for converting the linear motion from the steering rack into steering force, while the outer tie rod fine-tunes that motion and connects it to the wheel hub assembly.

Because both components are constantly subjected to steering pressure, vibrations and road shocks, they can wear out at different rates.

Inspecting both components ensures that no hidden looseness or damage is overlooked.

2. How to Inspect Inner Tie Rod Ends

If the outer tie rod ends appear to be in good condition after inspection, it’s time to check the inner ones.

As before, grasp the tire at the 3 and 9 o’clock positions, as was done in the previous movement test.

While carefully observing the inner portion of the steering linkage, where the tie rod connects to the steering rack, gently move the wheel back and forth.

If you observe movement coming from within the rubber boot area rather than the outer joint, this often indicates wear and tear in the inner tie rod end.

The movement may seem slight, but it can lead to steering instability or a rattling noise over bumps.

For a more thorough inspection, have an assistant slowly turn the steering wheel left and right while you observe the inner joint area.

Any delayed or jerky motion in response to steering input may indicate that the inner tie rod is beginning to fail.

3. Why Inspecting Both Ends Is Crucial

It’s common for vehicle owners or technicians to focus only on the outer tie rod ends because they are easier to see and access.

However, the inner tie rod ends are subjected to just as much mechanical stress and are equally critical to steering accuracy.

A failing inner tie rod end can cause the same problems as a failing outer one – including uneven tire wear, steering wander and alignment issues.

As both ends are connected in a single continuous linkage, a problem in either part affects the entire system.

Inspecting both ensures you accurately diagnose steering problems, rather than simply replacing one part only to have the other fail shortly afterward.

4. Ensuring Complete Steering Safety

By inspecting both the inner and outer tie rod ends, you can ensure your vehicle’s steering remains tight, responsive and safe.

This step not only confirms the condition of the entire tie rod assembly but also helps detect problems early, before they cause further damage to the suspension or tires.

Performing this inspection periodically, specially after driving over large potholes or rough roads, is the easiest and most effective way to maintain long-term steering reliability.

What to Do After Inspection

1. What to do if looseness or wear is found

Once you have completed the inspection and confirmed looseness, excessive movement, or worn tie rod ends, it is crucial to replace the damaged parts immediately.

A worn tie rod end directly impacts how well your vehicle can steer and maintain its alignment.

Driving with worn tie rod ends can lead to sudden wheel movements, increasing the risk of losing control, specially at high speeds or while turning.

Wear also causes uneven tire contact with the road surface, resulting in premature or irregular tire wear.

Replacing the affected tie rod ends promptly prevents further damage to the steering rack, suspension components and tires.

When replacing, ensure the new tie rod ends meet your vehicle’s specifications in terms of size, thread type and joint design for proper fit and reliable performance.

2. The Importance of Wheel Alignment After Replacement

After replacing one or both tie rod ends, a wheel alignment should always be performed.

This is because the tie rod ends are a critical part of the vehicle’s alignment geometry.

Even a slight change in the length or position of the tie rod alters the toe angle, which directly affects how straight and smoothly the car tracks on the road.

Without proper alignment, the vehicle may pull to one side, the steering wheel may be off-center and tire wear will increase.

A professional alignment ensures the wheels are in the correct position according to factory specifications, guaranteeing stable steering and even tire wear.

Skipping this step often leads to persistent handling problems, regardless of how new the parts are.

3. When to Seek Professional Confirmation

If you are unsure about your inspection results or lack experience working with steering components, it’s always best to have your findings double-checked by a certified mechanic.

Accurately diagnosing tie rod wear can sometimes be challenging because other components, such as ball joints or control arm bushings, can produce similar symptoms.

A professional technician has the proper tools to safely lift the vehicle, take precise measurements and confirm whether the problem lies with the tie rod ends or other steering parts.

Seeking expert confirmation ensures the correct repairs are made and maintains the overall safety and performance of your vehicle.

4. Ensuring Continued Steering Safety

After the inspection and any necessary adjustments, take some time to carefully test drive your vehicle.

Pay attention to how the steering feels – it should be smooth, stable and responsive.

Regularly checking and maintaining your tie rod ends is one of the easiest and most effective ways to keep your vehicle safe and easy to control.

Taking action as soon as wear is detected and having a professional alignment and verification performed helps extend the life of your tires, protect your steering components and ensure reliable driving performance for many miles to come.

Read More:

Basic Safety Tips and Common Mistakes

Also, there are studies that shows that the tie rod ends can fail not only from the single heavy impacts but it does with the gradual metal fatigue which can accelerated by corrosion and lost lubrication as well. And whenever the rubber boot tears and grease leaks out, then the contaminants and water actually reaches to the joint and speed wear, which is why the combined effect with everyday steering loads can eventually causes cracking or buckling of the tie rod ends.[¹]

1. The Importance of Using Proper Support

Safety should always come first when inspecting or working on any part of your vehicle’s suspension or steering system.

One of the most common and dangerous mistakes people make is relying solely on a floor jack to support the vehicle.

Jacks are designed only for lifting, not for support and they can fail suddenly due to pressure loss or slippage.

Always place sturdy jack stands under the frame or designated support points before performing any inspection under the vehicle.

This ensures complete stability and prevents the car from falling if the jack fails.

Working safely also means wearing gloves and eye protection to shield against sharp edges, dirt and grease to prevent injuries during the inspection.

2. Avoiding Damage from Overtightening or Excessive Force

Another mistake many beginners make when inspecting or adjusting tie rod ends is applying too much force.

Tie rod ends are precision parts with threaded connections that can be easily damaged if handled carelessly.

Overtightening nuts or applying excessive force to the tie rod joint with a pry bar can strip the threads, crack the joint housing, or even bend the connecting parts.

When inspecting, apply only light, steady pressure – just enough to check for movement without damaging the parts.

If a nut or joint seems stuck, use the correct penetrating oil or professional tools instead of applying excessive force.

Being careful and patient helps prevent costly damage and ensures your tie rod ends remain in proper working condition.

3. Recognizing and Responding to Early Warning Signs

Many steering problems can be prevented if early warning signs are taken seriously.

Noises like knocking or rattling, wandering steering, uneven tire wear, or vibrations in the steering wheel often indicate early wear in the tie rods.

Ignoring these symptoms allows the damage to spread, eventually leading to steering instability or complete steering failure while driving.

When a tie rod end becomes excessively worn or completely separates, it can cause a wheel to lose steering control—a serious safety hazard.

Paying attention to these early signs and performing regular inspections helps catch problems before they become dangerous.

4. Ensuring Long-Term Steering Safety

By following proper safety procedures and avoiding common mistakes, you not only protect yourself during inspections but also extend the lifespan of your vehicle’s steering system.

Safe practices build good habits that make maintenance more effective and reliable.

Every time you work under a vehicle, prioritize stability, gentle handling and awareness of symptoms.

These small steps ensure your tie rod inspection process is safe and reliable and that your car remains in optimal condition for everyday driving.

Conclusion – How to Check Tie Rod Ends

Yes, tie rod ends is such a small joint but it literally carries enormous responsibility to hold the power to control your car’s direction, balance and road stability, if you ignore them then you can have the consequences related to vibrations, uneven tire wear and steering may feel not balanced or controlled.

In essence, these small yet powerful parts are responsible for transmitting every steering input directly to the wheels.

When they begin to wear out or become loose, it not only alters the feel of driving but also compromises the car’s handling on the road.

Faulty tie rod ends can lead to steering problems, uneven tire wear and poor wheel alignment, impacting both your safety and driving confidence.

Regularly inspecting your tie rod ends is the easiest and most effective way to prevent these issues and extend the lifespan of your suspension system.

A thorough inspection—both visual and physical—helps you detect any looseness, corrosion, or movement within the joint before it escalates into a major problem.

Performing these checks at regular intervals, specially after driving on rough or uneven roads, ensures that the tie rod ends remain tight, lubricated and responsive.

If you ever notice any signs of wear or looseness, replace the affected part immediately and have a professional perform a wheel alignment to ensure proper steering performance.

So, that’s it from this one and if you still have confusion related to this guide, please comment that down below.

Frequently Asked Questions

Q1. What is a tie rod end and what does it do?

Answer: A tie rod end is a small joint that connects your vehicle’s steering rack to the wheel assembly. Its main function is to transmit your steering movements directly to the wheels so that when you turn the steering wheel, the tires respond immediately and accurately. It also helps keep the wheels properly aligned while driving. Although small, the tie rod end is one of the most crucial parts of the steering system, as even a slight looseness or malfunction can lead to poor handling and uneven tire wear.

Q2. How do I know if my tie rod ends are bad?

Answer: You can often tell if your tie rod ends are bad if you start hearing knocking noises when turning, feel looseness in the steering wheel, or notice uneven tire wear. The car may pull to one side or the steering wheel may not easily return to the center after making a turn. Sometimes you may also feel vibrations in the steering wheel, specially over bumps or at high speeds. Checking for looseness in the tie rod, torn rubber boots, or grease leaks can confirm whether they need replacing.

Q3. How often should I have my tie rod ends inspected?

Answer: It’s a good idea to have your tie rod ends inspected at least once or twice a year, or every time you have your tires rotated or aligned. You should also have them checked after hitting potholes, curbs, or driving on very rough roads, as this can put extra stress on the steering components. Regular inspections help you catch early signs of wear before they lead to serious steering problems or tire damage.

Q4. Can I drive with bad tie rod ends?

Answer: Driving with a faulty tie rod end is unsafe and not recommended. A damaged or loose tie rod end can cause wheel misalignment, leading to the car pulling to one side and reduced steering control. In severe cases, if the tie rod end completely fails, you could lose the ability to control one of your wheels, potentially causing a serious accident. It’s best to have it replaced immediately as soon as you notice any signs of damage.

Q5. What happens if a tie rod end breaks while driving?

Answer: If a tie rod end breaks while driving, the wheel connected to it will lose its connection to the steering system. This means you will lose the ability to control the direction of that wheel, causing the car to swerve suddenly or become completely uncontrollable. Driving will likely become unsafe and the vehicle will need to be towed. This is why checking and maintaining your tie rod ends is crucial for your safety.

References:

[1] Investigation of a Vehicle Tie Rod Failure In Relation To the Forces Acting On the Suspension System

https://www.ajer.org/papers/v5%2806%29/Z-B050602080217.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.