Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

It is true that you need something special and specific kind of windshield wipers for your Semi Truck, as the wipers must work really hard to keep the road truly visible and the driver safe in harsh weather conditions.

Basically, a fully loaded semi truck can weight up to 80,000 pounds which is literally a lot to handle, so during the heavy rain, snow or dust storms, the visibility is the most important factor that keeps you safe and that’s why you need really high quality wiper blades that perform best with your Semi Truck.

As well as, according to the FMCSA, the poor visibility actually contributes to the thousand of the truck-related accidents every year, which shows that how important it is to have the properly maintained wiper system.

Even, you should know that: Semi Truck windshield wipers actually differs greatly from those which are used on the passenger cars, as they are designed for larger windshields, higher wind resistance and even for longer operating hours as well in to tackle challenging conditions.

That’s why we have come up with these 5 Best Windshield Wipers for Semi Trucks so that you can have high-quality windshield wipers that can maintain the cleanliness of your Semi Truck and help you to maintain control over massive commercial vehicles that travels thousands of miles every months.

The 5 Best Windshield Wipers for Semi Trucks – Truly Durable Blades

The features are the actual game changer that makes them truly suitable for Semi Trucks in all-weather conditions, as these are truly reliable in terms of performance and durable enough to give the service for the longer period of time.

#1. TRICO

Yes, this ultra-protective windshield wiper for Semi Truck comes that supports 24 inch + 24 inch dimensions and it is designed by Trico: which is actually one of the most trusted names in commercial vehicle industry, as it is known for its strong construction, consistent wiping performance and truly long lasting materials.

The blades are designed to handle the large windshield curves which is found on the semi trucks, also they comes with innovative VorTec aerofoil which is truly wind-resistant up to the 135 mph which basically means that it will keep your blades intact for a safer view throughout the journey.

Plus, the aerodynamic style of this blade actually converts the wind force into the maximum windshield contact as well, which is great thing to have in windshield wipers.

#2. VEIGEIR

Now, VEIGEIR comes with this high quality windshield wiper for Semi Trucks, which is actually made with durable materials that resist aging, cracking and heat damage as well, which literally makes them suitable for semi trucks that have to travel through mixed climates.

As well as, it comes in 24 inch + 24 inch wiper blades so you can easily fit it on your Semi Truck of the same dimension.

Not only this, it is made with aerodynamic frames to maintain constant pressure across the entire glass surface, which is why it literally reduces streaks and noise quiet effectively.

#3. AUTOBOO

So, this Semi Truck windshield wiper is manufactured by AUTOBOO, basically it has 22 inch + 22 inch of windshield blades that is why it becomes suitable for semi-truck that supports same dimension.

Also, it is made of high quality rubber and stainless steel materials that makes them truly durable for all-weather conditions.

Along with this, it comes with dual high tenacity memory spring steel sheet, with an asymmetrical wind spoiler and both of the feature actually help it to deliver uniform pressure distribution and lot better windshield contact.

#4. TRICO

Again, TRICO designed this strong and high performance windshield wiper for semi truck that supports 22 inch + 22 inch blade sizes.

The design is heavy-duty, as uses high quality rubber material that actually provides a sleek and shiny clean without the chatter and noise as well.

Even the frame are build to handle the vibration and wind pressure experienced at the highway speeds as well.

#5. Clix Wipers

So, this time Clix Wipers comes with this high quality wiper that can withstand in tough working environments.

This is great for those Semi Trucks that supports 26 inch + 26 inch blade dimensions, even it has durable construction as it is made with steel frame and natural rubber that provides long-lasting performance.

At First, You Should Understand Semi-Truck Windshield Wipers

1. Differences Between Semi-Truck Wipers and Passenger Car Wipers

Semi-truck windshield wipers are designed for a completely different level of performance than those on regular cars.

Passenger car wipers clean only a relatively small windshield and typically operate at low speeds, while a semi-truck’s windshield is much larger and taller, capable of withstanding high wind pressure and heavy road debris.

Semi-truck wipers are designed to operate continuously for long periods of time in extreme conditions such as heavy rain, snowfall and dust storms.

They are typically made of reinforced materials that can withstand high pressure and are designed for stronger wiper pressure to fully cover the larger glass surface.

Another major difference is the mounting and motor strength.

Truck wiper systems use industrial-grade motors and linkages that provide greater torque to the larger blades so they can operate efficiently without losing speed or contact, even at highway speeds or in icy conditions.

2. Overview of Heavy-Duty Design and Materials

Heavy-duty wiper blades used on semi-trucks are built for durability, strength and reliability.

They typically feature stainless steel or powder-coated metal frames that resist corrosion from moisture, salt and road grime.

Wiper elements are made of natural rubber composites, silicone compounds, or double-layer synthetic materials that can withstand intense heat, extreme cold and UV radiation without cracking or hardening.

Some heavy-duty wipers also come with aerodynamic spoilers that help maintain firm contact with the windshield at high speeds, reducing lift caused by air drag.

Manufacturers often use thick claws and tension springs to evenly distribute pressure across the windshield, helping to prevent streaks and ensure continuous visibility.

This durable design ensures that wipers can handle thousands of operational cycles before wearing out, which is important for long-haul trucks that spend most of their lives on highways in varying weather conditions.

3. Description of Size and Fitting Requirements for Different Truck Models

The size and fitment of windshield wipers for semi-trucks vary widely depending on the vehicle model and brand.

Unlike passenger cars, where sizes are more standardized, truck wiper lengths can range from 26 inches to 32 inches or even longer, depending on the height and curvature of the windshield.

For example, trucks such as the Freightliner Cascadia, Volvo VNL, Peterbilt 579 and Kenworth T680 require specific blade lengths and arm connector types to ensure proper fitment.

Choosing the wrong size can reduce wiper coverage or even put mechanical stress on the wiper motor.

To ensure compatibility, truck owners or fleet managers should always consult the manufacturer’s manual or confirm original equipment specifications before purchasing a replacement.

Modern heavy-duty wipers often include universal adapters or multi-fit systems, simplifying installation on various commercial truck brands while maintaining the required wiping angle and reach.

4. The Role of Wiper Arms, Blades and Motor in Performance

The performance of a semi-truck’s windshield wiper system depends on proper coordination between the wiper arms, blades and motor.

The wiper motor is the power source, generating the torque necessary to move the blades steadily across the large windshield, despite strong wind resistance.

The wiper arms act as the link between the motor and blades, applying even pressure to ensure full contact with the glass.

They are typically made of strong metal or composite materials that can resist bending and corrosion.

The blades themselves are a crucial connecting component, responsible for effectively wiping away rain, snow and dirt without leaving any traces.

When these three parts work together efficiently, they provide smooth, quiet and consistent operation, ensuring clear visibility in all weather conditions.

Regular maintenance of the arms and motor, such as cleaning joints and checking for loose connections, ensures long-lasting performance and prevents wiper failure during crucial driving moments.

Types of Windshield Wipers for Semi-Trucks

1. Conventional Frame Wipers – Durability and Simplicity

Conventional frame wipers are the most traditional and widely used type on semi-trucks due to their simple design and proven reliability.

They consist of a metal frame with multiple pressure points that hold the rubber blades firmly to the windshield.

This structure helps distribute pressure evenly, providing a clean and consistent wipe across the large surface area of truck windshields.

Their biggest advantage is their durability and easy maintenance, as they can withstand long periods of continuous use and are easily replaced when worn.

Conventional wipers are often made of galvanized or stainless steel to resist corrosion from road salt, rain and dirt.

Their simple design makes them cost-effective, which is why many fleet operators prefer them for routine maintenance.

However, these can sometimes cause problems in high-speed conditions or during heavy snowfall, as the open frame design can allow debris or snow to accumulate, affecting performance.

2. Beam-Style Wipers – Aerodynamics and All-Weather Use

Beam-style wipers are a modern upgrade designed for improved performance in all types of weather.

Unlike traditional frame wipers, beam blades have no external metal frame.

Instead, they feature a one-piece curved design made of flexible rubber or silicone with an integrated tension spring.

This structure allows them to apply even pressure along the entire length of the blade, resulting in a smooth and unmarked wiper.

Beam-style wipers are especially useful for high-speed highway driving, as their aerodynamic shape reduces wind pressure and keeps them firmly pressed against the windshield.

Due to their low-profile design, they are also more resistant to clogging by snow or debris.

Many truck drivers choose beam-style wipers for long-distance routes through areas with variable weather, as they perform equally well in rain, snow and heat.

They typically last longer and offer quieter operation than traditional frame wipers, although they cost slightly more.

3. Hybrid Wipers – A Blend of Flexibility and Strength

Hybrid windshield wipers combine the best features of both traditional and beam-style designs, offering a balance between strength, performance and flexibility.

Their outer casing is as strong as a traditional frame for durability, but the inner casing uses a curved, spring-loaded structure like beam wipers for even pressure distribution.

This combination helps hybrid wipers deliver consistent wiping results in both light rain and heavy storms.

Their semi-enclosed structure prevents ice buildup and maintains a strong frame that can handle the weight of water and debris during long-distance travel.

The rubber or silicone used in hybrid wipers is often coated with a water-repellent compound, which increases visibility by quickly collecting rainwater.

These wipers are an excellent choice for truck drivers who travel in various climates, as they are suitable for both hot and cold weather and maintain excellent contact with the curved windshields found on modern semi-trucks.

4. Winter Wipers – Designed to Prevent Freezing and Ice Buildup

Winter wipers are specifically designed to operate in freezing temperatures, blizzards and icy conditions.

They feature a fully enclosed rubber boot or cover that protects the metal frame and joints from ice and snow buildup.

This cover prevents the wiper mechanism from freezing, allowing it to maintain flexibility and full speed even in sub-zero temperatures.

The rubber compound used in winter blades remains soft and flexible even in the cold, whereas traditional rubber can harden and lose its effectiveness.

These wipers are designed to handle heavy slush and thick snow, which are common on northern highways during the winter months.

Many brands also design winter wipers with reinforced tension springs to maintain firm contact with the glass despite the added weight of snow.

Although primarily designed for cold climates, many professional drivers use winter wipers seasonally because they are reliable in extreme conditions and able to maintain visibility even in inclement weather.

Quality Material and Construction of the Windshield Wipers for Semi Trucks

1. Rubber vs Silicone Blades – Durability and Cleaning Quality

The material used in a wiper blade greatly impacts its performance, durability and overall cleaning quality.

Most conventional semi-truck wiper blades are made of natural rubber, which provides a soft and flexible edge that fits snugly against the windshield surface.

Rubber blades initially provide excellent cleaning, but deteriorate quickly when exposed to sunlight, ozone and harsh weather.

Over time, the rubber can harden or crack, causing streaks and uneven cleaning.

In contrast, silicone blades are designed to last longer because they are resistant to heat, UV rays and chemical damage.

Silicone blades also deposit a thin, invisible water-repellent layer on the windshield during use, allowing raindrops to easily roll off.

This layer improves visibility even when the wipers are not running.

Although silicone blades are typically more expensive initially, they last twice as long as rubber blades and maintain consistent cleaning performance even in extreme temperatures, making them a smart long-term investment for truck drivers who face frequent weather changes during long-distance trips.

2. Stainless Steel and Coated Metal Frames for Corrosion Resistance

The frame of a semi-truck windshield wiper must be strong enough to withstand high wind pressure, heavy rain and hours of continuous use.

Therefore, most heavy-duty wipers are made of stainless steel or powder-coated metal, which provide excellent resistance against rust and corrosion.

Stainless steel frames are especially useful for trucks traveling through humid or coastal areas where salt in the air can quickly damage untreated metal.

The powder coating provides an additional protective layer, protecting the frame from oxidation and maintaining its strength and appearance even after prolonged exposure to dirt, chemicals and road grime.

Some modern wipers are also made of composite materials or reinforced plastics, which are lightweight but strong enough to resist bending or warping.

These robust structures ensure the blade maintains firm and even contact with the windshield, which is crucial for clear visibility and smooth operation on the windshields of large trucks.

3. Aerodynamic Spoiler Design for High-Speed Performance

Semi-trucks travel long distances at high speeds, often faces strong winds and turbulent air.

To maintain stable contact between the wiper blade and the windshield in such conditions, many modern wipers feature aerodynamic spoiler designs.

These spoilers are carefully designed extensions or shapes in the wiper body that use air pressure to press the blade more firmly against the glass when driving at high speeds.

This prevents the wiper from lifting or sliding, a common problem with flat or traditional designs.

The aerodynamic structure also helps reduce drag and noise, making operation smoother and quieter.

For larger semi-trucks with wide, slightly curved windshields, this design improvement makes a significant difference in performance, especially during heavy rain or thunderstorms.

It also reduces wear on the wiper motor, as aerodynamic lift reduces stress on the balancing mechanism, extending the lifespan of the entire wiper system.

4. Weather-Resistant Coating and UV Protection Features

Semi-truck windshield wipers are exposed to sun, rain, dust, snow and road chemicals almost every day.

To withstand such harsh conditions, manufacturers apply weather-resistant coatings and UV protection treatments to both the rubber and metal components of the wipers.

These coatings prevent the rubber from drying out or cracking when exposed to ultraviolet rays, a major cause of wiper flex over time.

UV-protected blades retain their elasticity and wiping edge longer, ensuring consistent and streak-free performance.

In addition to UV protection, many heavy-duty wipers feature anti-ozone and hydrophobic coatings that repel water and resist chemical corrosion caused by de-icing agents or fuel residue.

Some premium models also feature graphite or Teflon coatings, which help the blades glide smoothly across the windshield and reduce friction noise.

These weatherproofing enhancements help truck drivers maintain optimal visibility in all weather conditions and reduce the need for frequent wiper replacement, ultimately saving both time and maintenance costs.

How to Choose the Right Size and Fit

1. How to Measure Windshield Wipers for Semi-Trucks

Choosing the right size of windshield wipers for semi-trucks starts with accurate measurement, as the wrong size can reduce visibility, cause streaks, or even damage the wiper motor.

To measure wipers correctly, it’s best to check the existing blade length from end to end, according to the curve of the wiper arm.

Most truck wipers are measured in inches and this measurement should be taken from both the driver and passenger sides, as their lengths may not always be the same.

A more accurate method is to consult the vehicle’s manual or manufacturer’s sizing chart, as semi-trucks often have different windshield designs that require specific blade lengths and sizes.

When measuring, drivers should also consider the arc, or sweep area, of the wiper so that the blades can cover the entire windshield without extending beyond the edge of the glass.

Taking the correct measurements ensures smooth operation, improved visibility and longevity of both the blade and wiper motor systems.

2. Manufacturer Compatibility – Freightliner, Volvo, Peterbilt, Kenworth, Mack

Each truck manufacturer designs its windshield and wiper mounting systems differently, so ensuring compatibility is important.

For example, Freightliner Cascadia models typically use 26- to 28-inch wipers, while Volvo VNL trucks may require 28- to 30-inch blades, depending on the year and model.

Peterbilt 579s and Kenworth T680s often have larger curved windshields, requiring beam-style or hybrid wipers that can maintain full contact with the surface, typically in the 28- to 32-inch range.

Meanwhile, Mack Anthem and International LT series trucks may use specific adapter fittings or hook connections to match their specific wiper arm designs.

Because of these variations, it’s important for drivers or fleet managers to double-check the compatibility list provided by the wiper brand before purchasing.

Many wiper manufacturers now include vehicle-specific fit guides or online lookup tools, allowing users to find the exact blade length and attachment type for their truck’s make, model and year without any guesswork.

3. The Importance of the Correct Mounting Adapter and Arm Connection

The mounting adapter or connector is one of the most important but often overlooked parts of the wiper system.

It’s a small mechanism that securely connects the blade to the wiper arm.

Semi-trucks use a variety of connectors, such as hook-style, side pin, bayonet and top lock adapters, depending on the make and model of the truck.

Using the wrong adapter can cause the blade to loosen or detach during operation, especially at high speeds or in heavy rain.

High-quality truck wipers often include universal or multi-adapter kits, allowing them to be fitted to different wiper arms without any modifications.

It’s also important to ensure that the adapter locks tightly and allows the blades to move freely and smoothly across the windshield.

Regularly inspecting the mounting area for wear, corrosion, or looseness helps prevent problems and ensures the entire wiper system operates efficiently and safely under all driving conditions.

4. Common Sizes and Which Model Fits Which – 26″, 28″, 32″

Semi-truck windshield wipers come in several common sizes, typically ranging from 26 inches to 32 inches.

The most popular sizes used on commercial trucks are 26-inch, 28-inch and 32-inch blades, but some specialized models may require slightly different measurements.

For example, the Freightliner Cascadia and Kenworth T680 often use 28-inch wipers, while Volvo VNL models may require 30- or 32-inch blades to cover their wide, curved windshields.

Peterbilt 579 trucks often use 32-inch blades to achieve complete wiping coverage on the driver’s side.

Choosing the right size is not only about fitting the arm, but also ensuring that the blades provide maximum visibility without hitting the windshield trim or overlapping with the opposite blade.

Drivers may need replacement wipers.

Always refer to the original equipment specifications or consult a reliable online fitment guide before purchasing.

Do not use blades that are even an inch shorter.

Doing so for too long can result in poor cleaning, mechanical stress and premature motor failure, jeopardizing safety during long-distance travel in inclement weather.

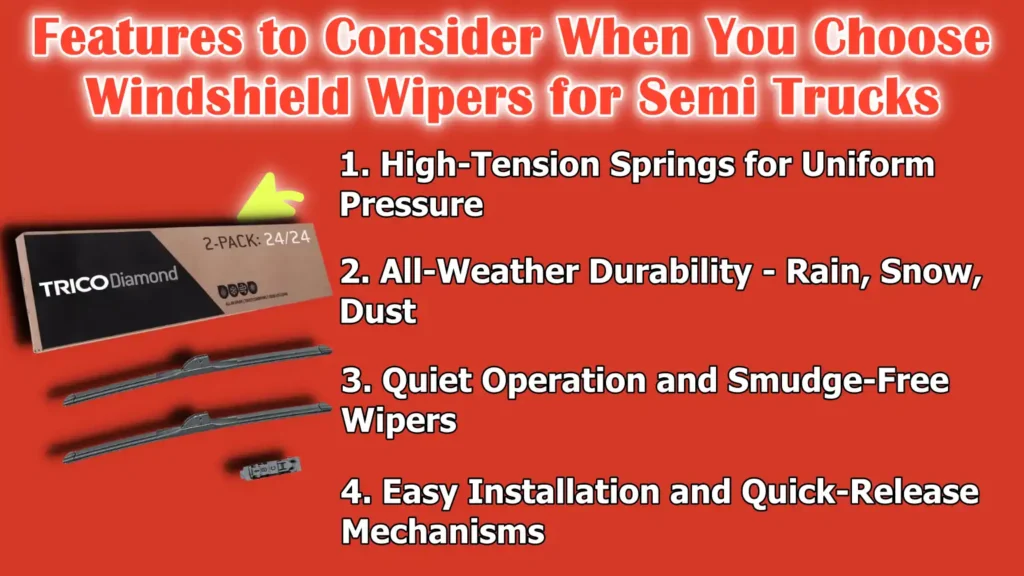

Features to Consider When You Choose Windshield Wipers for Semi Trucks

1. High-Tension Springs for Uniform Pressure

One of the most important features that determines the efficiency of windshield wipers on semi-trucks is the use of high-tension springs.

These springs are designed to apply uniform pressure across the entire length of the blade, ensuring it remains in full contact with the windshield surface from one end to the other.

This uniform pressure is important because truck windshields are large, slightly curved and exposed to strong winds, which can lift the wipers off the glass if the pressure is uneven.

High-tension springs responses this force, ensuring even and effective cleaning by the wipers even at highway speeds or during heavy rain.

Without adequate tension, parts of the windshield may become covered with water or debris, creating blind spots that reduce visibility.

Premium truck wipers use stainless steel or coated spring mechanisms that resist corrosion and maintain their strength over time, allowing wipers to perform reliably for thousands of operating cycles in varying weather and road conditions.

2. All-Weather Durability – Rain, Snow, Dust

Semi-trucks operate in all types of weather—from the cold of the northern states to the hot, dusty highways of the south—so windshield wipers must be designed to perform in all weather conditions.

All-weather durability means that wipers can handle rain, snow, ice, mud and dust without losing their flexibility or wiping ability.

Strong blades are typically made of advanced rubber or silicone compounds that remain soft in cold temperatures and prevent drying or cracking in extreme heat.

Some wipers also have a protective coating that repels water and prevents ice and dirt from accumulating.

The frame and connectors are typically made of corrosion-resistant materials like stainless steel or powder-coated metal, ensuring long-lasting performance even when exposed to moisture and road salt.

This level of durability is essential for truck drivers who travel thousands of miles in varying weather conditions, as reliable wipers help maintain visibility during long trips and prevent unexpected downtime.

3. Quiet Operation and Smudge-Free Wipers

A well-designed wiper not only cleans the windshield effectively but also operates smoothly and quietly.

Modern semi-truck wipers use specially shaped blades and friction-reducing coatings like graphite or Teflon that glide across the glass without squeaking or clicking.

These materials reduce friction between the blades and the windshield, making the wiper’s movement quieter and less distracting to the driver.

Smudge-free wipers are equally important, as even small streaks at night or in direct sunlight can cause glare, strain the eyes and reduce safety.

High-quality wipers achieve this by maintaining uniform edge pressure and using wiper elements precisely cut to conform to the glass surface.

For professional truck drivers who spend long hours on the road, the smooth and quiet performance of wipers not only improves visibility but also increases comfort and concentration, especially during continuous rain or snowfall.

4. Easy Installation and Quick-Release Mechanisms

Semi-truck drivers often change their windshield wipers on the road or at truck stops, so easy installation is a major advantage.

Many modern wiper designs now include quick-release or snap-on mechanisms that allow drivers to change blades in minutes without the need for tools.

These systems typically use universal adapters that fit various arm types, such as hook, pin, or bayonet connections, making the process simple and hassle-free.

A secure connection is crucial because a poorly fitted blade can break or underperform during operation.

Some premium wipers also feature indicator strips or built-in wear markers that indicate the need for blade replacement, helping drivers maintain their wipers before performance declines.

Easy-to-install designs save time during maintenance checks, reduce downtime for fleet operations and ensure wipers always perform at their best, even when weather conditions suddenly change.

How to Maintain and Replace Windshield Wipers for Semi Trucks

1. Signs It’s Time to Replace Windshield Wipers

Knowing when to replace windshield wipers is essential to maintaining clear visibility and safe driving conditions.

The most common signs include streaks, peeling, or squeaking noises during operation, indicating that the rubber edge has worn unevenly or hardened.

Another obvious sign is when the blade doesn’t make full contact with the windshield, allowing some water or dirt to escape.

If the wiper begins to crack or vibrate during operation, it could mean the blade has lost its flexibility or the arm has lost tension.

Drivers may also notice cracks, torn, or worn edges on the rubber surface, often caused by UV exposure, ozone damage, or extreme temperature changes.

In semi-trucks that travel long distances in varying climates, these problems may appear faster than in regular passenger vehicles.

Whenever these symptoms appear, it’s a clear sign that the wipers need to be replaced to ensure optimal visibility and prevent excessive strain on the wiper motor system.

2. Cleaning and Maintenance Methods to Extend Life

Regular cleaning and maintenance can significantly extend the life of windshield wipers and improve their performance.

One of the easiest and most effective methods is to wipe the rubber edge of the blade with a clean cloth soaked in mild soap and water or rubbing alcohol.

This removes dirt, oil and road residue that can cause streaks and wear.

Keeping the windshield clean is equally important, as debris or sand accumulated on the glass can act like sandpaper, causing the wiper edge to wear faster.

During colder months, truck drivers should lift the wipers off the windshield when parking to prevent them from freezing to the glass, which could damage the blades or motor during operation.

Check the wiper arms for rust, corrosion, or loose fittings to ensure the blades are properly ventilated.

Applying a silicone conditioner or protectant keeps the rubber flexible and can reduce cracking caused by heat or sunlight.

Regular care not only extends the lifespan of wipers but also ensures they function effectively even in changing weather.

3. Recommended Replacement Interval

Although replacement frequency depends on driving conditions and climate, most experts recommend replacing semi-truck windshield wipers every six to twelve months.

Trucks traveling in extreme weather, such as heavy rain, snowfall, or dusty terrain, may require replacement more frequently, sometimes every four to six months.

Frequent use, sun exposure and temperature fluctuations can all reduce wiper lifespan.

Drivers should pay attention not only to timing, but also to visual and performance cues—any streaks, creaking, or signs of decreased wiping effectiveness should signal the need for replacement.

Many fleet maintenance programs include regular inspections of wiper condition as part of scheduled servicing to prevent unexpected malfunctions.

Using high-quality blades with UV-resistant rubber or silicone compounds can help extend replacement intervals while maintaining clear visibility and reducing operating costs over time.

4. Troubleshooting Common Wiper Problems – Streaks, Cracking, Skipping

When windshield wipers aren’t working properly, identifying and correcting the cause can prevent unnecessary replacement.

Streaks typically form when dirt or residue accumulates on the rubber blades or the windshield, so cleaning both surfaces often resolves the problem.

If streaks persist, it may indicate a worn or hardened edge that needs replacement.

Chattering—when wipers make a vibrating sound while running—is often caused by uneven pressure or misalignment of the wiper arms.

Ensuring the arms are tight and in the correct position can restore smooth movement.

Skipping, which leaves water gaps on the windshield, can occur when the rubber loses flexibility or when the curvature of the wiper blade doesn’t match the glass.

In such cases, replacing the blade or adjusting the arm tension usually resolves the problem.

Regularly lubricating the arm joints and checking the mounting adapters can also prevent these problems from recurring.

By understanding these common wiper problems and addressing them promptly, truck drivers can maintain reliable performance and reduce the risk of poor visibility in difficult driving conditions.

Read More:

How to Install Windshield Wipers for Semi Trucks

1. Remove Old Blades and Install New Ones

Replacing windshield wipers on a semi-truck may seem simple, but doing it correctly ensures proper performance and safety.

The first step is to carefully lift the wiper arm away from the windshield until it locks in the upright position.

This will prevent the spring-loaded arm from jerking back and damaging the glass.

Next, locate the connector that connects the wiper blade to the arm.

Most semi-trucks use a hook, pin, or side-lock adapter, depending on the manufacturer.

To remove the old blade, press the release tab or slide the connector latch, then gently slide the wiper down to remove it from the hook.

Before installing the new blade, check the wiper arm for any rust, bends, or weaknesses that could affect performance.

Then, align the new wiper blade connector with the arm and slide it in until it is securely in place.

Pull the blade gently to ensure it locks into place and doesn’t loosen while driving.

After attaching both blades, gently return the arms to the windshield to avoid any sudden jerks or scratches.

2. Tips for Ensuring Proper Attachment and Alignment

Proper attachment and alignment are crucial for even pressure distribution and effective wiper cleaning.

Before finalizing the installation, check that both wiper blades are parallel to the bottom edge of the windshield and equidistant from each side.

Incorrect alignment can cause streaks, rattles, or cause the wipers to not fully attach, reducing visibility in poor weather.

If the wipers appear uneven, slightly adjust the position of the arm by loosening the mounting nut on the arm base and placing it at the correct resting angle.

Ensure the adapter used matches the model and type of wiper arm, as even a slight variation can cause problems with the wiper arm fitting.

After installation, it’s a good idea to thoroughly clean the windshield so that no dirt or residue obstructs the new blades.

This helps ensure smooth and quiet operation from the start.

3. Safety Precautions During Installation

Safety is often overlooked when replacing wipers, but it’s crucial, especially for semi-trucks with large windshields and heavy wiper arms.

Always turn off the ignition before starting the vehicle and ensure the wipers are in the “off” position.

When lifting the wiper arms, hold them firmly, as the spring tension can cause them to snap back onto the glass with such force that they break or become damaged.

Placing a soft cloth or towel under the arm on the windshield while replacing the blades can help prevent damage from accidental impact.

It’s also important to use both hands when removing or installing wipers to maintain control.

Avoid forcefully attaching the connectors, as excessive pressure can break the clips or bend the arm joint.

Following these simple safety steps reduces the risk of injury or damage during installation.

4. Post-Installation Performance Check

After installing new wipers, test them to ensure they are working properly before driving in rain or snow.

First, spray windshield washer fluid or use a damp cloth to wet the glass.

Turn on the wipers and observe their movement on the windshield.

The blades should move smoothly, evenly and quietly, without streaks or gaps.

If there is any noise, uneven movement, or visible slippage, recheck the attachment to confirm the blades are properly locked and aligned.

Ensure the wiper arms apply equal pressure to the windshield and adjust the arm tension if necessary.

For semi-trucks with multiple wipers or extended blades, verify that both sides move synchronously without overlapping or colliding.

Performing this test immediately after installation helps to detect any fitting issues early and guarantees reliable visibility and wiping performance over long distances or in extreme weather conditions.

How to Ensure Working in Various Seasonal Conditions

1. How Temperature and Climate Affect Wiper Performance

Temperature and weather conditions play a major role in the performance of windshield wipers on semi-trucks.

Excessive heat can cause the rubber in the wiper blades to dry out, harden, or crack, reducing their flexibility and the wiper’s cleaning ability.

In hot climates or summer months, the rubber can also become sticky, causing streaks or scratches on the windshield.

Conversely, in cold environments, the rubber can harden and lose its ability to maintain even contact with the glass, leaving dirt streaks or missed spots.

Exposure to rain, dust and snow can increase wear, especially on long-haul trucks that travel through varying weather conditions.

Constant UV radiation can weaken the blades’ molecular structure, while road salt and dirt can corrode the metal wiper frame.

Understanding how these environmental factors affect wiper performance helps drivers choose the right blade material and plan maintenance before visibility or safety problems arise due to seasonal changes.

2. Choosing Winter-Grade Blades for Cold Regions

Winter-grade wiper blades are essential for drivers who frequently operate in snowy or icy areas.

These specialized blades are made from a heavy and durable rubber compound that remains flexible even in sub-zero temperatures.

Many winter blades have a closed or rubber-booted design that covers the moving parts, preventing snow, ice and mud from accumulating in the joints.

Some premium winter wipers also use silicone-based rubber, which naturally resists freezing and maintains smooth movement on the windshield.

As semi-trucks have large windshields and are more exposed to cold winds, using standard wipers in such conditions often reduces visibility and increases wear.

Winter blades are designed with stronger frames or reinforced hinges so they can handle the additional weight of snow and ice without bending.

Using these blades ensures regular wiper cleaning and reduces the risk of frozen wipers sticking to the glass, which can strain the motor and shorten component life.

3. Protecting wipers from snow and ice damage during parking

Taking preventative measures when parking in cold or icy conditions can significantly extend the life of windshield wipers.

One effective method is to lift the wiper arms away from the windshield before parking to prevent them from freezing overnight.

When ice accumulates on the windshield, it is important not to operate the wipers until the surface has completely thawed.

Operating wipers on frozen glass can break the rubber edges, damage the frame, or even burn out the motor.

Using a windshield cover or de-icing spray can also protect the blades from cold temperatures.

In areas where it snows frequently, parking the truck in a sheltered or heated area can prevent ice from accumulating on the wipers.

Regularly removing snow from the cowl area—the base of the windshield where the wipers are mounted—prevents clogging and mechanical stress.

These simple preventative measures help keep wipers flexible, reduce wear from ice and maintain their cleaning effectiveness even in harsh winters.

Cost and Value Analysis of Windshield Wipers for Semi Trucks

1. Average Price Range for Heavy-Duty Truck Wipers

The price of windshield wipers for semi-trucks can vary significantly depending on their size, design and material quality.

On average, a standard pair of heavy-duty wiper blades costs between $20 and $60 per blade, depending on the brand and model.

Beginner options with basic rubber blades and metal frames are at the lower end of this range, while high-performance or winter-specific blades with advanced coatings or enclosed designs cost more.

Some premium-grade wipers, especially those made with silicone or reinforced aerodynamic structures, can cost more than $80 per blade but offer greater durability and improved performance in harsh conditions.

Fleet operators who maintain many trucks often purchase in bulk, which can reduce the per-unit cost.

It’s important for drivers and fleet managers to remember that although wipers are relatively inexpensive compared to other truck components, their role in ensuring visibility and safety makes them one of the most valuable maintenance investments.

2. Cost-Benefit Comparison Between Standard and Premium Options

When comparing standard wipers and premium models, the difference lies not only in price, but also in performance, lifespan and maintenance frequency.

Standard rubber wipers are affordable and easy to replace, but typically last six to nine months with regular use.

They can wear out quickly in extreme heat, heavy rain, or snowy areas.

On the other hand, premium blades are designed from silicone or coated natural rubber that can withstand UV exposure, temperature changes and chemical pollutants for longer—often lasting one and a half to two years with proper care.

Premium models also have more robust frames made of stainless steel or high-strength composites that resist corrosion and bending under pressure.

Although premium wipers may have a higher initial investment, they reduce replacement frequency, improve wiping quality and ensure consistent performance over long distances.

For professional drivers and fleets, this balance of cost and reliability often makes premium blades a more economical choice over time.

3. Long-Term Savings from High-Quality Blades

Investing in high-quality windshield wipers results in long-term savings by reducing both replacement costs and potential safety risks.

Premium-grade blades retain their shape and flexibility for longer, meaning fewer replacements are required each year.

Over time, this can reduce maintenance costs by 30-40%, especially for trucks that drive millions of miles annually.

Durable materials like silicone or graphite-coated rubber reduce windshield friction, providing not only clear visibility but also protecting against microscopic scratches caused by debris accumulating on the glass surface.

It is really helpful to have hydrophobic coatings as that can actually reduce the wet-glass load and improves the visibility between the wipes, but whenever the coatings wear out then you must have to reapplied according to the manufacturer’s guidance.[¹]

Preventing this damage reduces the likelihood of costly windshield replacements.

Additionally, high-performance wipers prevent streaks or slippage that can obscure the driver’s view, reducing the risk of accidents and downtime due to poor weather conditions.

In large fleets, even small improvements in wiper longevity and performance can result in substantial savings across multiple vehicles.

So, while premium blades have a higher initial cost, their extended service life, improved visibility and reduced replacement frequency make them a smart and cost-effective investment for any truck operator or logistics company focused on long-term reliability and safety.

Conclusion – Best Windshield Wipers for Semi Trucks

The windshield wipers are not just that they provides you a clear window during rain, snow or dusty conditions, but they actually preserve safety, focus and control so that you can perform better under all conditions.

These components can withstand some of the harshest working environments—from freezing temperatures and heavy snowfall to intense heat and rough road dirt.

High-quality wipers, made from durable materials like silicone or reinforced rubber and equipped with corrosion-resistant frames, provide clear visibility even in the most demanding conditions.

By understanding how size, material and design affect performance, drivers and fleet managers can make better purchasing decisions that improve safety and reduce long-term maintenance costs.

Regular inspection, cleaning and timely replacement of wipers prevent streaking, creaking, or slippage, which can impact visibility.

Premium options, although more expensive initially, often offer significant long-term value through durability, reduced wear and fewer replacements.

Fleet experts and professional drivers agree that windshield wipers are an essential investment rather than a disposable accessory.

They not only increase driving confidence but also protect expensive windshields from microscopic scratches and damage.

Ultimately, choosing the right wipers and maintaining them properly ensures a safer, more efficient and more reliable driving experience for every mile travelled.

Now, that’s it from this one and you can ask questions below this guide.

Frequently Asked Questions

Q1. How often should semi-truck windshield wipers be replaced?

Semi-truck windshield wipers should generally be replaced every six to twelve months. However, this depends on how often the truck is used and the weather. Trucks operating in areas with heavy rain, snowfall, or high temperatures may require replacement more frequently—sometimes every four to six months. Over time, the rubber or silicone edge of the wiper blade wears out, hardens, or cracks, reducing its ability to clean the windshield properly. Replacing wipers on time ensures clear visibility and reduces strain on the wiper motor system.

Q2. What is the difference between regular car wipers and semi-truck wipers?

Answer: The main differences are size, strength and durability. Semi-truck windshield wipers are much larger than those used in passenger cars, often 26 to 32 inches long. To handle the larger windshield surface and greater air resistance faced by trucks at highway speeds, they are made from stronger materials such as stainless steel or coated metal. Truck wipers have a stronger rubber compound and stronger joints that can withstand prolonged use, dust and harsh weather. Car wipers are lighter and not designed to withstand the harsh conditions trucks face daily.

Q3. What are the best wiper blades for semi-trucks?

Answer: The best wiper blades depend on where and how the truck is driven. For general use, sturdy conventional or hybrid wipers are a good choice because they balance strength and flexibility. Beam-style wipers are best for all-season use because they provide aerodynamic efficiency and even pressure distribution. For trucks operating in snow, ice, or frozen conditions, winter wiper blades are ideal because they have a protective rubber boot that prevents ice buildup. Many drivers also prefer silicone blades because they last longer and provide smooth, streak-free cleaning in all weather conditions.

Q4. How do I choose the right size wiper blade for my semi-truck?

Answer: To find the correct wiper blade size, check the truck’s owner’s manual or measure the old wipers already installed. Most semi-trucks use blades 26 to 32 inches long, although the size may vary depending on the model. Common examples include 28-inch blades for Freightliner or Volvo trucks and 32-inch blades for larger Kenworth or Peterbilt models. It’s important to ensure the new blades match the type of arm connector—such as hooks, pins, or side locks—so they’ll be securely in place. Using the correct size will ensure the windshield is completely covered and runs smoothly without any overlaps or gaps.

Q5. How do I install new windshield wipers on a semi truck?

Answer: Installing new wipers is easy if done carefully. Lift the wiper arm off the windshield until it locks into place. Press the release tab or slide the latch on the old blade to remove it from the arm. Align the new wiper blade connector with the arm and press until it clicks securely into place. Before lowering the arm back down, check that it is firmly in place and properly aligned with the windshield. Finally, test the wipers by spraying washer fluid to ensure they are running smoothly and cleaning the glass without streaks or noise.

Q6. Why do windshield wipers leave streaks or gaps?

Answer: Streaks and gaps usually occur when the rubber on the blade becomes hard, cracked, or dirty. Accumulation of dirt, dust and oil on the windshield or wiper edges can cause uneven contact with the glass. In some cases, the wiper arms may be misaligned or the spring tension may be loose, causing uneven pressure. Cleaning the wipers with a soft cloth and mild soap may help, but if streaks persist, it’s usually a sign that the blades need to be replaced. Ensuring that both the windshield and wiper blades are clean and properly aligned will ensure smooth and clear cleaning.

Q7. How can I prevent my wipers from freezing in winter?

Answer: To prevent windshield wipers from freezing in winter, keep them away from the windshield when parking so they don’t stick to the glass. Never operate the wipers when the windshield is covered with ice, as this can break the rubber or damage the motor. You can also use winter-appropriate wiper blades, which have protective covers and flexible rubber to prevent ice buildup. Applying de-icing windshield fluid or using a windshield cover can help protect both the glass and wipers on cold nights.

References:

THE INFLUENCE OF HYDROPНОВІС WINDSHIELD COATING ON DRIVER VISUAL PERFORMANCE

https://www.supracanada.ca/wp-content/uploads/2017/07/Hydrophobic-UMTRI-97-31full-study.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.