Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

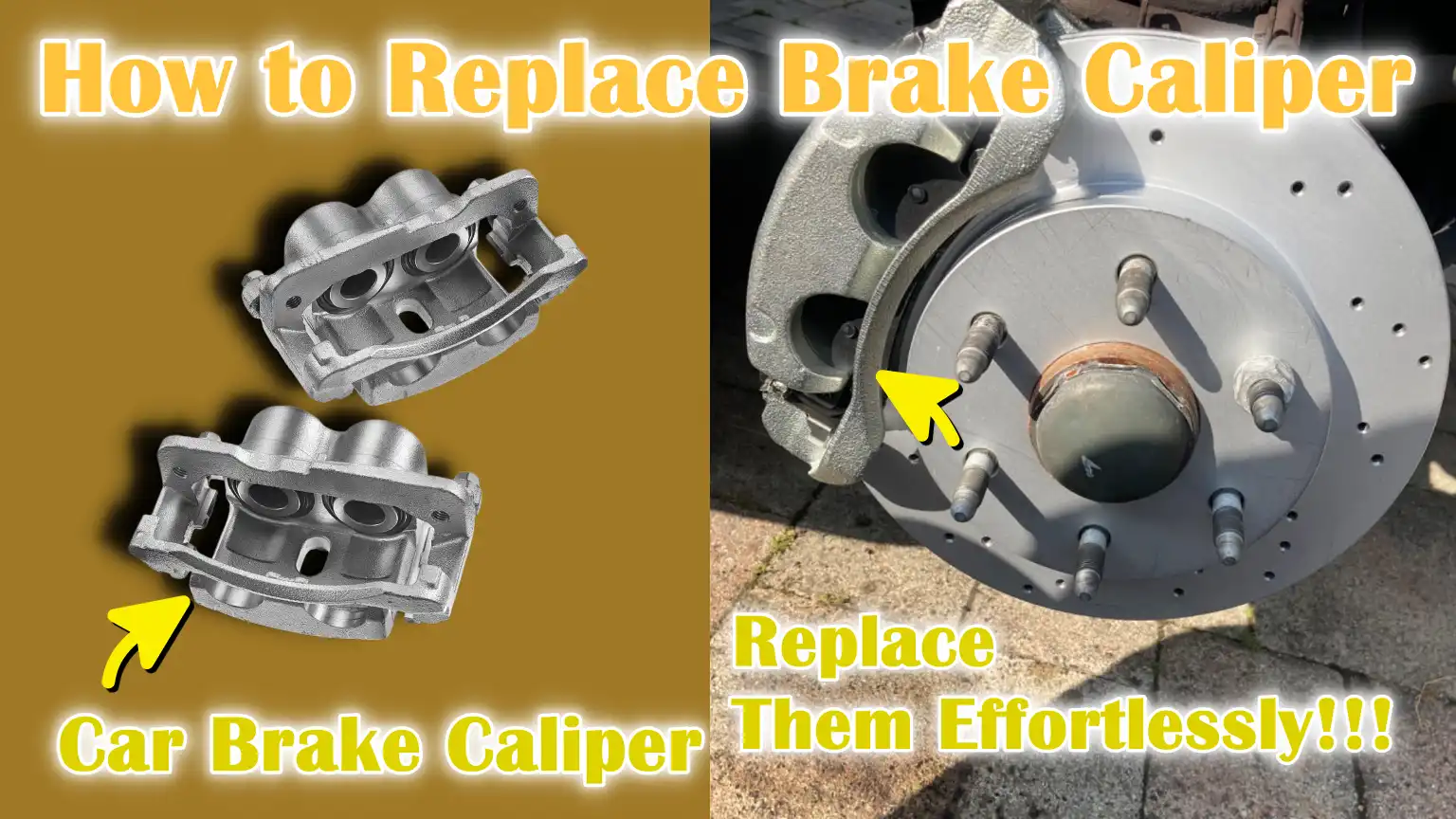

When your brake caliper starts to sticking or leaking then this is the horrific thing to have on your vehicle, which is why you should always focus on the safety and replace them to keep your braking system strong and fully responsive to face all kinds of conditions.

As, the caliper is the part that actually squeezes the brake pads against the spinning rotor and in that way it stops your car.

But, it’s just a man made things that can be worn out because of heat, moisture, corrosion, worn seals, constant hydraulic pressure and even it is been a long time in service, so all these things can causes a caliper to stick, leak or lose its ability to apply the even braking force all the time: which is very dangerous thing.

As well as, there’s a studies that shows that the modern brake systems actually operates under pressures between 800 and 2,000 PSI during the hard braking situations, which literally means that even a small caliper fault can instantly reduce the stopping power and it actually increases stopping distance as well.

Not only this, a failing caliper can also cause uneven pad wear, can pull to one side, brake drag, overheating and extra strain on the suspension parts as well.

So, basically you need to understand how a caliper actually works and know How to Replace Brake Caliper so that you can avoid unsafe driving conditions.

Now, Let’s Understand About Brake Calipers

Brake calipers are one of the most important parts of a vehicle’s braking system because they are responsible for converting hydraulic pressure from brake fluid into clamping force that slows the wheels.

When you press the brake pedal, the master cylinder sends high-pressure fluid through the brake lines and the caliper uses this pressure to push the brake pads against the rotating rotor.

Most modern vehicles generate between 800 and 2,000 PSI of brake pressure when braking hard, which reflects the amount of work the caliper has to do every second.

A well-functioning caliper ensures smooth and even braking, prevents lateral friction and helps maintain a stable stopping distance.

As calipers are constantly exposed to heat, vibration and moisture, understanding how they work makes it easier for drivers to detect early signs of wear and maintain safe braking performance.

1. What a Brake Caliper Does

The brake caliper acts like a strong clamp that uses hydraulic pressure to press the brake pads onto a metal rotor attached to the wheel.

The caliper contains pistons that move outward when pressurized brake fluid enters and this movement creates the friction needed to slow or stop the car.

Most calipers are made of durable materials such as cast iron or aluminum because they must withstand extreme heat, which can exceed 200°C during regular braking.

A properly functioning caliper applies equal force to both sides of the rotor, allowing the car to stop in a straight line.

If the caliper becomes stuck or loses pressure, the braking force becomes uneven, increasing stopping distances and reducing driving safety.

Knowing what a caliper does helps car owners understand why timely maintenance is important.

2. Types of Brake Calipers – Floating vs Fixed

Brake calipers generally come in two main types: floating calipers and fixed calipers.

A floating caliper has one or two pistons on only one side and slides back and forth on guide pins so that both brake pads apply equal force to the rotor.

This design is common in everyday cars because it is lighter, simpler and more economical.

Fixed calipers, on the other hand, have pistons on both sides of the rotor and don’t slide.

Instead, the pads are pushed inward simultaneously from both sides.

Fixed calipers are commonly found in performance cars because they provide stronger, more consistent braking and better pedal feel.

However, they are more complex and expensive.

Understanding the difference between floating and fixed calipers helps you choose the right replacement and understand each type’s behavior during braking.

3. How Caliper Pads Interact with the Rotor and Brake Fluid

The brake caliper, together with the pads, rotor and brake fluid, forms a complete braking system.

When the brake pedal is pressed, brake fluid flows through the lines and pushes the caliper piston forward.

The pistons then press the pads onto the rotor and friction between the pads and the rotating rotor slows the vehicle.

The brake fluid must remain clean and air-free, as air bubbles reduce pressure and create a soft, unsafe pedal feel.

The rotor must also be smooth and evenly worn so that the pads can remain in full contact without vibration.

The caliper pistons and seals must move freely to balance the braking force on both sides of the car.

If any part of this interaction fails, braking force is weakened, the car may veer to one side and stopping distances increase.

Understanding this relationship helps drivers more accurately diagnose brake problems and maintain overall braking health.

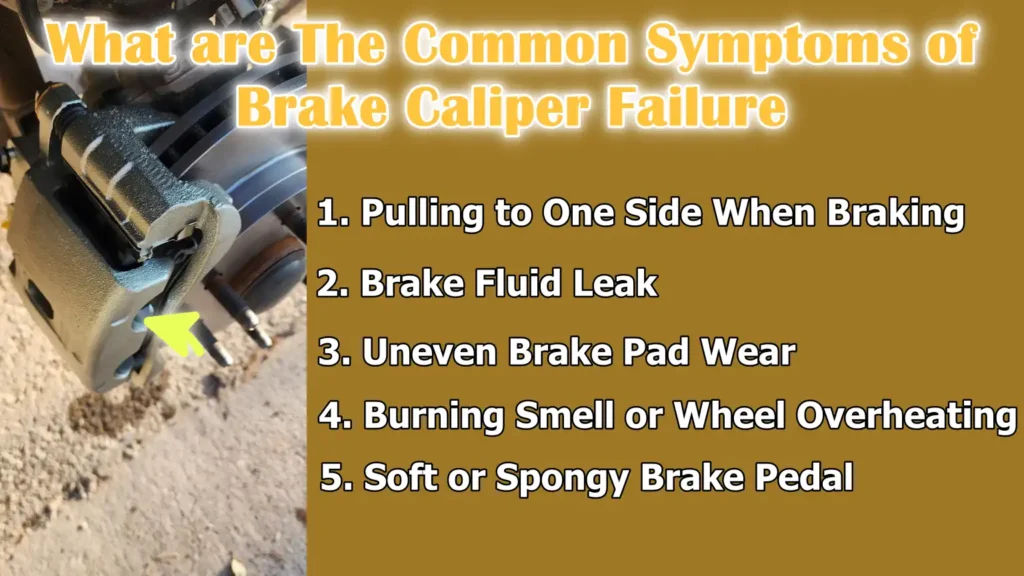

What are The Common Symptoms of Brake Caliper Failure

A bad brake caliper can affect the entire braking system because it controls how evenly the brake pads apply pressure to the rotor.

When a caliper becomes stuck, leaks, or loses hydraulic pressure, it alters the amount of force transmitted to the wheel and even a slight difference can reduce stopping power.

A worn or damaged caliper can accumulate heat, increase friction, or leak fluid, causing significant changes in vehicle behavior during braking.

As the caliper operates under high pressure, often exceeding 1,000 PSI, any weakness in its seal or piston movement immediately becomes a safety concern.

Understanding the symptoms of caliper failure helps drivers identify problems early, prevent brake failure and avoid costly damage to the rotor, pads and wheel bearings.

Each symptom provides important clues about what’s wrong and how quickly the problem needs to be fixed.

1. Pulling to One Side When Braking

When a vehicle pulls to one side when braking, it usually means that one caliper is applying more force than the other.

This can happen when the caliper piston is stuck, the guide pins stop sliding smoothly, or the caliper fails to open after braking.

A worn caliper creates more friction on one wheel, causing the car to shake or pull when braking.

This problem may be mild at first, but it can become dangerous at high speeds because the uneven braking force reduces control and stability.

Drivers often first recognize this symptom because the steering wheel appears to pull in one direction when braking.

Early detection can prevent serious rotor damage and unsafe driving conditions.

2. Brake Fluid Leak

Brake fluid leaks are a serious symptom because the caliper piston seals must remain airtight to maintain hydraulic pressure.

If fluid begins to leak from around the piston, bleeder valve, or brake hose connections, the braking system immediately loses power.

Even a small leak can reduce pressure enough to increase stopping distance or cause the pedal to sink when braking.

Brake fluid is designed to withstand high temperatures, but when it leaks, it contaminates surrounding components and reduces the brake system’s ability to function properly.

Leaks can cause air to enter the lines, further weakening braking power.

Checking for moisture, wet spots, or fluid marks around the wheel can help detect this problem before it becomes dangerous.

3. Uneven Brake Pad Wear

Uneven brake pad wear is one of the most common symptoms of a bad caliper because a stuck piston or a frozen slide pin prevents the pads from applying even pressure to the rotor.

When one pad wears faster than the other, it means the caliper is applying uneven pressure or not releasing pressure properly.

This uneven pressure makes the brakes noisy, reduces friction efficiency and can also wear the rotor surface unevenly.

If left untreated, uneven pad wear can lead to brake vibration, overheating and more expensive repairs.

Understanding this symptom helps drivers detect caliper problems early by checking the pad thickness during routine maintenance.

4. Burning Smell or Wheel Overheating

A burning smell or excessive heat around the wheel usually means the caliper is stuck and won’t open even after applying the brakes.

When the caliper is engaged, it keeps the brake pads pressed against the rotor even when the driver isn’t braking.

This constant friction generates extreme heat, which can exceed several hundred degrees Celsius, causing smoke, a strong burning smell and sometimes discoloration of the rotor.

If the temperature rises too high, overheating can damage wheel bearings, brake hoses and even tire rubber.

This symptom should never be ignored as it indicates internal wear of the caliper and can cause it to lock up while driving.

5. Soft or Spongy Brake Pedal

A soft or spongy brake pedal often indicates that air or moisture has entered the brake system due to a leaking or worn caliper seal.

Brake fluid cannot be compressed, but air can be compressed, causing the pedal to feel soft and reducing pressure on the caliper.

This can result in problems such as weak braking, long stopping distances and the pedal sinking into the ground.

A bad caliper can also cause internal fluid bypass, where fluid flows over the piston seal instead of pushing it against it.

This reduces braking force and makes the pedal feel unstable or inconsistent.

Identifying a weak pedal early helps prevent complete brake failure and ensures necessary system repairs.

Tools

| Category / Title | Description (Easy Words, Detailed, Helpful) |

|---|---|

| Hand tools – wrenches, sockets, torque wrench | These are the main tools used for removing and installing brake components. A wrench or socket helps loosen caliper bolts and a torque wrench ensures bolts are tightened to the exact pressure recommended by the manufacturer. Proper torque also prevents bolts from loosening and breaking. Using the right tools keeps the job safe and can prevent damage to the brake system. |

| Lifting equipment – jack, stands | The jack raises the car off the ground and jack stands hold it firmly in place while the work is being done. Stands are necessary because a jack can suddenly slip or tip over. Using strong and stable lifting equipment ensures that the car doesn’t fall, which protects both the worker and the parts being repaired. |

| Replacement caliper and hardware | This includes a new brake caliper, new rubber seals, new slide pins and the bolts or washers that came with the caliper. Many new calipers also include brackets, while some require reusing old brackets. Having the right caliper ensures proper compression, smooth piston movement and safe stopping. |

| Brake fluid and bleeding tools | Brake fluid is needed to refill the system after installing a new caliper. Clean brake fluid keeps moisture out and maintains stable hydraulic pressure. Bleeding equipment such as a clear hose, catch bottle, or vacuum bleeder helps remove air trapped in the brake lines. Air inside the system reduces the stopping power of the brakes, so good bleeding equipment is essential. |

| Safety gear | Essential safety equipment includes gloves, safety glasses and protective clothing. Brake fluid can irritate the skin and eyes and tools can slip while working. Wearing the proper safety equipment prevents injuries and keeps repairs clean and controlled. |

| Optional helpful tools | These are additional tools that make the job easier, but aren’t necessary. A wire brush helps clean rust from the bracket, brake cleaner removes dust and oil and a bungee cord or rope can hold the caliper in place while you work. A piston compression tool can also help push the piston back in easily. These optional tools save time and make the job even easier. |

Basic Safety Preparation You Should Take

Safety preparation is one of the most important steps when replacing brake calipers because you’re working with heavy parts, extreme hydraulic pressure, the vehicle’s weight and a chemical fluid that can damage skin, paint and eyes.

The brake system operates under high heat and pressure, so even a small mistake can cause equipment to slip, the vehicle to fall, or cause injury from contact with brake fluid.

Properly preparing your workspace helps you remain stable, secure the car and focus on the repair without worrying about unexpected movements.

Simple steps like securing the wheels, wearing protective gear and using jack stands correctly can make the entire job easier and safer.

With proper preparation, even a novice can work confidently and avoid the most common mistakes during brake repair.

1. Parking on Level Ground

Parking the vehicle on level, solid ground ensures it stays in one place when you lift it.

A flat surface balances the vehicle’s weight and prevents it from rolling or tilting during repairs.

When working on slopes, gravity can push the vehicle forward or backward, causing the jack or stands to move.

A concrete driveway or garage floor is ideal because it provides firm support.

Starting on level ground reduces the risk of sudden movement when the car’s wheels are lifted.

2. Using Wheel Chocks

Wheel chocks are small blocks attached to the front or rear of the tires that rest on the ground.

They prevent the car from rolling when the other end of the tire is lifted to apply the brakes.

Even when the parking brake is engaged, wheel chocks provide an additional layer of safety, as brake systems can sometimes slip or lose grip, specially when working on calipers or lines.

Proper wheel chocking locks the wheels in place and ensures the car remains completely stationary during repairs.

3. Wearing Gloves and Eye Protection

Wearing gloves and eye protection protects you from brake dust, sharp edges, rust particles and brake fluid splashes.

Brake fluid can irritate the skin and cause damage if it gets into the eyes and gloves help prevent this by creating a protective shield.

Safety glasses protect your eyes from dust or rust that may enter the eyes when removing calipers or loosening bolts.

These simple safety devices protect you from common injuries and help you work without fear of sudden dangers.

4. Safe Handling of Brake Fluid

Brake fluid must be handled with care because it is corrosive and absorbs moisture quickly.

It can corrode car paint in seconds and cause skin irritation if it comes into direct contact.

Keeping brake fluid away from painted surfaces, open flames, or hot parts helps prevent accidents.

Using clean containers and keeping the bottle sealed when not in use maintains the quality of the fluid, as moisture in the air lowers its boiling point.

Safe operation ensures strong hydraulic pressure and prevents contamination of the brake system.

5. Ensuring Proper Position of Jack Stands

Proper jack stand position is important because the stands support the vehicle’s entire weight when working under or around the wheels.

Jack stands should be placed under strong lift points, such as the frame rails or manufacturer-recommended jacking points.

The jack should raise the vehicle high enough so that the stands are securely locked and the car rests firmly on the stands, not on the jack.

When the stands are in the correct position, the vehicle remains stable and does not fall or move, providing you with a safe working area around the brake assembly.

How to Prepare the Vehicle for Caliper Removal

Preparing the vehicle before caliper removal is a very important step as it lays the foundation for a safe and smooth repair.

This process involves loosening the wheel hardware, raising the vehicle steadily and ensuring the work area is open and clean.

The brake caliper is attached to heavy components such as the rotor, hub and suspension, so the vehicle must be fully supported and stable before starting.

Proper preparation helps prevent tools from slipping, wheels falling and sudden shifts in the vehicle’s weight.

It also provides clear access to the brake system so you can see the caliper, hoses, brackets and surrounding components.

When each step is done properly, the overall repair becomes easier, faster and safer for both beginners and experienced mechanics.

1. Loosening the Lug Nuts

Loosening the lug nuts while the vehicle is on the ground helps prevent the wheel from spinning when the wrench is turned.

Lug nuts are typically tightened tightly, sometimes over 100 foot-pounds, so loosening them quickly relieves the tension and stabilizes the car.

This step only requires a slight loosening, not a complete removal, as the wheel should remain in place until the vehicle is lifted.

Doing this while the car is in the air makes the wheel removal process safer and easier.

2. Raising the Vehicle

Raising the vehicle with a proper jack gives you enough space to remove the wheel and access the brake caliper.

The jack should be placed under a sturdy lifting point, usually recommended by the vehicle manufacturer, so that the weight of the car is lifted evenly.

Raising the car high enough ensures that the wheel can be removed without getting stuck in the ground or fender.

A slow and steady lift allows you to check for any movement or shift, ensuring the vehicle remains centered at a safe height on the jack.

3. Securing the Vehicle on Jack Stands

After lifting the car, placing it on jack stands ensures that it remains stable and does not fall during repairs.

Jack stands are designed to support the vehicle’s weight for long periods of time, while jacks are only for lifting.

The stands must be placed on solid support points to distribute the load evenly.

Once the car is fully resting on the stands, you should check for strong connections and ensure that the car does not move or wobble.

This step provides a safe working environment and prevents accidental vehicle movement.

4. Removing the Wheel

Removing the wheel exposes the brake system and provides easy access to the calipers, pads and rotors.

As the lug nuts are already loose, you can easily remove them now that the wheel is off the ground.

The wheel should come straight off the hub and keeping it nearby allows it to be reinstalled later without having to search for parts.

Removing the wheel also helps you check for any damage, leaks, or worn parts around the brake area before working on the caliper.

5. Inspecting the Brake Area

Inspecting the brake area helps you understand the condition of the caliper, rotor, pads and brake hoses before removing them.

You can check for signs such as fluid leaks, uneven pad wear, corrosion, or damaged hardware.

This inspection makes it easier to identify why the caliper is failing and whether other parts also need attention.

Inspecting the area beforehand helps avoid unexpected incidents during repairs and gives you a clear idea of which parts need to be replaced or cleaned.

A simple but careful inspection improves the quality of the entire job and helps ensure safe braking performance after the repair is complete.

How to Remove the Old Brake Caliper

Removing the old brake caliper is one of the most important steps in brake repair, as this component is responsible for applying pressure to the brake pads and safely stopping the vehicle.

A worn or stuck caliper can cause uneven braking, lateral friction, overheating and accelerated brake pad wear.

Therefore, performing this step correctly ensures that the new system will function properly.

When removing the caliper, the goal is to separate the caliper from the bracket, prevent brake fluid leaks and carefully detach all connected parts without damaging the brake line or rotor.

Each action requires attention and patience, but dividing it into clear steps simplifies the process.

1. Identifying the Caliper Bolts

The first step is to locate the main bolts that hold the caliper in place.

These bolts are usually found on the back of the caliper and may be covered by a rubber boot or dust cap.

Identifying the correct bolts can prevent accidentally loosening the caliper bracket bolts, which are often overtightened and not necessary for normal caliper removal.

Taking the time to find the correct bolts allows for easy caliper removal without unnecessary effort.

2. Removing the Caliper Slide Bolt

After locating the correct bolt, loosen and remove the slide bolts to separate the caliper from the mounting bracket.

Slide bolts allow the caliper to move slightly when braking, so they are designed to be removed with moderate torque.

Removing them evenly prevents the caliper from sticking or twisting.

Once these bolts are removed, the caliper is free enough to separate from the rotor.

3. Safely Disconnecting the Brake Hose

Before completely removing the caliper, carefully disconnect the brake hose attached to it.

The brake hose provides hydraulic pressure from the master cylinder, so disconnecting it will drain brake fluid.

Using the correct flare-nut wrench and holding the hose steady prevents the fitting from becoming bent or damaged.

A clean, controlled disconnection helps maintain the brake system and reduces the risk of future leaks.

4. Plugging or Capping Brake Lines to Prevent Leaks

As soon as the brake hose is removed, fluid may begin to drip from exposed brake lines.

It is important to plug or cap the brake line immediately to prevent fluid loss and air from entering the system.

Brake fluid contamination or air bubbles can weaken braking power, so sealing the line protects the hydraulic system.

A rubber plug, plastic cap, or even a temporary line clamp can be used to stop the flow.

5. Removing the Old Caliper from the Rotor

After removing the bolts and disconnecting the brake line, the old caliper can be removed from the rotor.

Sometimes it may be stuck due to rust or debris, but a gentle wiggle will loosen it.

Cleanly removing the caliper prevents accidental scratches on the rotor surface.

At this stage, the braking area is exposed for inspection before installing the new caliper.

6. Removing Brake Pads If Necessary

Sometimes, brake pads are left inside the old caliper when it is removed.

If the pads are to be reused or replaced, they should be removed now.

Removing the pads allows you to check their wear pattern and thickness.

A proper inspection helps confirm whether the old pads are still secure or whether new pads need to be installed with the caliper for better braking performance.

How to Prepare the New Brake Caliper

Preparing the new brake caliper is a crucial step because a properly configured caliper ensures smooth braking, even pad wear and reliable hydraulic pressure every time the driver presses the brake pedal.

Before installation, several checks and adjustments are necessary to ensure the caliper is in perfect working condition and correctly aligned with the vehicle.

This step also helps prevent brake noise, piston sticking and premature wear of the new pads.

Taking a few minutes to properly prepare the caliper increases its lifespan and ensures a safer braking system overall.

1. Inspecting the Piston Condition

The first step is to check the piston inside the new caliper to ensure it is rotating freely and is undamaged.

The piston is responsible for pushing the brake pads against the rotor, so it should glide smoothly without sticking or leaking.

A quick inspection for smooth edges, clean seals and proper lubrication confirms that the piston will apply the correct pressure when braking.

This simple check helps prevent future brake drag and uneven pad wear.

2. Ensuring Caliper Bracket Matching

The next step is to ensure that the caliper bracket is the correct size and shape for the vehicle’s rotor and mounting points.

Different cars use different caliper designs and even slight differences can cause alignment issues.

Matching the bracket ensures that the caliper remains straight on the rotor and applies even pressure during braking.

Proper matching also prevents vibration, noise and premature wear of brake components.

3. Brake Pad Transfer – If Applicable

If the new caliper does not already have pads fitted, the existing or new pads should be transferred.

This step ensures that the pads seat correctly inside the caliper without movement during braking.

Correct pad placement is crucial because it ensures full contact with the rotor surface and reduces the risk of uneven braking.

Checking that the pads are firmly and smoothly seated helps the brake system respond quickly and consistently.

4. Applying Proper Brake Grease to Pins and Contact Points

Before installation, it’s important to apply the correct brake grease to the slide pins and all metal-to-metal contact areas.

This grease helps the caliper move naturally during braking and prevents sticking, noise and rust.

Proper lubrication reduces friction and heat buildup, increasing the lifespan of the brake pads and caliper.

Applying grease to the necessary parts ensures quiet, smooth and long-lasting braking performance.

How to Install a New Brake Caliper

Installing a new brake caliper is one of the most important steps in restoring proper braking performance, as correct positioning, tightening and assembly of the caliper are essential for safe operation of the hydraulic system.

A new caliper, equipped with proper alignment and correctly tightened hardware, will apply even pressure to the brake pads, allowing the vehicle to stop smoothly and predictably.

During installation, it is important to pay attention to hose connections, torque values and sealing points so that the brake system can generate and maintain the correct hydraulic pressure.

This step ensures that the new caliper works in conjunction with the rotor, pads and brake fluid to provide safe and reliable braking in everyday driving.

1. Caliper Position

The new caliper should be placed on top of the brake rotor in the exact same position from which the old one was removed.

Correct positioning ensures that the pistons are perfectly aligned with the brake pads and that the pads sit evenly on both sides of the rotor.

When the caliper is in the correct position, braking force is distributed evenly across the rotor surface, reducing vibration, noise and wear.

Ensuring this alignment also helps prevent friction or uneven braking, which can generate heat and damage other brake components.

2. Reattaching the Caliper to the Bracket

Once in the correct position, the caliper must be mounted on the bracket that holds it in place.

This bracket is essential because it stabilizes the caliper during braking and prevents unnecessary movement.

Correctly reattaching the caliper ensures that the pads remain centered and do not move even under hard braking.

A secure bracket connection helps maintain consistent stopping power and reduces the likelihood of brake noise or misalignment over time.

3. Tightening the Slide Pin to the Torque Specification

The slide pin should be tightened to the manufacturer’s recommended torque level so that the caliper moves smoothly but remains firmly attached.

These slide pins allow the caliper to move slightly during braking, ensuring that both pads apply equal pressure to the rotor.

Tightening them too loosely can cause rattling or uneven braking, while overtightening them can hinder acceleration and cause the brakes to jam.

Using the correct torque ensures long-lasting reliability and smooth brake operation.

4. Reconnecting the Brake Hose

The brake hose must be securely reconnected so that brake fluid can flow from the master cylinder to the caliper without leakage.

This hose carries the hydraulic pressure that propels the piston, so a proper connection is essential for safe braking.

When reconnecting the hose, it is important to ensure that the copper washers or sealing surfaces are clean and properly seated to create a strong seal.

A proper connection prevents air from entering the brake system and maintains strong and consistent braking power.

5. Check for Leaks or Loose Connections

After all connections have been made, the entire area should be inspected to ensure there are no leaks or loose parts.

Even a small leak can cause air to enter the braking system, leading to a loss of pressure and a soft brake pedal.

Careful inspection also ensures that all fittings are properly tightened and that brake hoses are not bent or stretched.

This final check confirms that the braking system is ready for bleeding and ensures that the new caliper will operate safely under pressure.

Read More:

How to Bleed the Brake System

Bleeding the brake system after installing a new caliper is a crucial step because it removes air trapped in the brake lines and restores full hydraulic pressure.

Air in the brake system is dangerous because air is easily compressed, while brake fluid is not.

This means that even a small amount of air can make the pedal soft or spongy and significantly reduce the brakes’ stopping power.

Bleeding ensures that only clean brake fluid is filled in the lines so that the caliper pistons can operate with full force when the brake pedal is pressed.

A proper bleeding system improves pedal feel, reduces braking distance and helps the brake system operate smoothly and reliably, specially during sudden stops.

1. Purpose of Bleeding

The main purpose of bleeding the brake system is to remove air bubbles that may have become trapped when the brake hose was disconnected.

Air bubbles cause inconsistent braking because they interfere with the pressure sent to the calipers by the master cylinder.

Removing this air ensures a firm brake pedal feel, quick response from the calipers and even distribution of braking force across all wheels.

It also protects internal brake components from corrosion and uneven wear caused by improper fluid pressure.

2. Manual Bleeding Method

Manual bleeding is the most common method and involves depressing the brake pedal while someone opens and closes the bleeder valve on the caliper.

This method removes fluid and air from the system at a controlled speed using the pedal.

It is simple and effective, but requires two people and should be done slowly to avoid damaging the master cylinder.

Manual bleeding is often preferred because it provides direct feedback on how much air is being removed and improves pedal feel.

3. Gravity Bleeding Method

Gravity bleeding uses the natural downward flow of brake fluid to remove air from the system.

Once the bleeder valve is opened, brake fluid slowly flows out, carrying air bubbles with it.

This method is simple and does not require pumping the brake pedal, making it less effective on older brake systems.

Although gravity bleeding may take longer than other methods, it is still a good option when working alone or removing a small amount of air.

4. Vacuum or Pressure Bleeding

Vacuum and pressure bleeding use specialized equipment to speed up and simplify the bleeding process.

Vacuum bleeders draw fluid from the system using suction, while pressure bleeders push fluid out of the master cylinder.

Both methods are very effective at removing air quickly and are often used by professional mechanics.

They help prevent fluid contamination and reduce the risk of introducing new air during the bleeding process.

These tools are specially useful when replacing multiple calipers or when brake lines are completely empty.

5. Correct Bleeding Order

Using the correct bleeding order is important because it ensures that air is removed from the longest brake lines first.

In most vehicles, bleeding starts with the wheel farthest from the master cylinder and ends with the wheel closest to it.

Following the proper order prevents air from getting trapped in certain lines and ensures uniform pressure throughout the system.

The correct order also helps maintain consistent braking performance and reduces the chance of having to repeat the process.

6. Refilling Brake Fluid During Bleeding

During bleeding, it is important to keep the master cylinder reservoir filled to the proper level to prevent new air from entering the system.

The fluid level should be checked after every few cycles, specially during manual bleeding, as fluid drains quickly.

Keeping the reservoir full ensures a continuous flow of clean brake fluid and prevents the need to restart the bleeding process.

Once all the air has been removed, the final fluid level must be within the manufacturer’s recommended range for the system to operate safely and efficiently.

How to Reassemble and Final Checks

Reassembly and final checks are essential steps to ensure the brake system is safe, stable and ready for actual driving after a caliper replacement.

This step involves returning all components to their proper positions and verifying that everything is secure and functioning properly.

Minor mistakes, such as loose lug nuts or spilled brake fluid on painted surfaces, can cause safety hazards or long-term damage.

Carefully completing these final tasks ensures that the new caliper operates smoothly, the wheel turns freely and hydraulic pressure is fully restored.

When reassembly is done correctly, the driver can expect a firm brake pedal, strong stopping power and a reliable brake system that responds quickly in all driving conditions.

Even, caliper sticking can appear suddenly after months of little or no use, which is why you need to clean it, give it proper anti-corrosion treatment and replacement is needed for badly corroded pins or pistons as it is the part of any caliper replacement.[¹]

1. Cleaning Spilled Brake Fluid

Before reinstalling any part, it is important to clean up spilled brake fluid, as brake fluid is corrosive and can damage paint, rubber and electrical components.

Wiping and rinsing the area with water helps prevent long-term damage.

Clean surfaces also make it easier to detect leaks during final inspection.

Ensuring the workspace is clean removes contamination and prevents chemical damage to surrounding parts.

2. Reinstalling the Wheel

Reinstalling the wheel involves placing it back on the hub in the same direction it was removed.

The wheel must be snug against the hub so it rotates evenly and doesn’t wobble.

Installing the wheel correctly ensures that the tire maintains full contact with the road and that braking force is effectively transmitted.

A properly positioned wheel also prevents vibration during driving and prevents unnecessary stress on the brake assembly.

3. Lowering the Vehicle

Lowering the vehicle from jack stands should be done slowly and carefully to avoid sudden changes in load.

Once the jack supports the vehicle again, the stands can be removed and the vehicle can be fully lowered to the ground.

This step stabilizes the vehicle so that the lug nuts can be tightened with the correct torque.

Lowering the vehicle correctly helps maintain balance and prevents accidental damage to the suspension or underbody.

4. Tightening the Lug Nuts to the Proper Torque

Once the vehicle is securely on the ground, tighten the lug nuts to the manufacturer’s recommended torque specification.

This ensures that the wheel is securely in place, but do not overtighten.

Proper torque prevents the wheel from loosening during driving and prevents the brake rotor from warping due to uneven pressure.

Adhering to the recommended torque also helps maintain uniform wear on the wheel studs and keep the wheel properly aligned.

5. Pumping the Brake Pedal to Restore Pressure

Before driving, pump the brake pedal several times to rebuild hydraulic pressure in the newly installed caliper.

This forces the brake pads to press against the rotor and expels any remaining air pockets near the caliper.

Pumping the pedal ensures immediate braking while the vehicle is moving.

A firm, consistent tap on the pedal confirms that the caliper is functioning properly and the bleeding process was successful.

6. Final Check of Brake Fluid Level

The final step is to check the brake fluid level in the master cylinder to ensure it is within the recommended standard.

Any drop in fluid level after bleeding and pumping may indicate that air has been released or that the new caliper has been overfilled.

Topping up the fluid ensures the system has enough volume to operate safely under heat and pressure.

A correct final level helps maintain consistent braking performance and prevents warning lights or pressure-related problems while driving.

How to Test Drive and Post-Installation Inspection

A test drive and post-installation inspection are essential steps to ensure that the new brake caliper is functioning correctly under actual driving conditions.

Even if everything appears perfect during installation, only a real road test can truly reveal how the caliper responds to speed, heat, pressure and repeated braking.

This step helps you verify that the system generates and maintains hydraulic pressure, the pedal feels firm and the vehicle stops smoothly without strain or unusual noises.

It also ensures that there are no leaks from the hose connections or bleeder valve, which can only be seen when the system is at full pressure.

By taking a careful test drive and monitoring the brake behavior during the first few miles, you can ensure that the new caliper is installed properly and that the entire braking system remains safe, reliable and consistent.

1. Slow-Speed Brake Test

Slow-speed brake testing helps confirm that the new caliper is gripping the rotor evenly and that the vehicle responds as expected when the brake pedal is pressed.

At low speeds, typically 5 to 10 mph, you can test the brakes without applying pressure to the new parts.

This gentle test ensures there is no drag on one side, no grinding noise and no uneven stopping force.

It also helps the brake pads make smooth and even contact with the rotor surface.

2. Checking Pedal Response

Checking pedal response is important because a healthy brake system should provide a firm, consistent pedal feel that doesn’t sink or throb.

After installing the new caliper, the pedal should respond quickly and pressurize without any sponginess.

A soft pedal usually means there’s still air trapped in the system or that fluid is leaking under pressure.

A responsive pedal confirms that hydraulic pressure is working properly and the caliper pistons are operating smoothly.

3. Checking for Leaks After the Drive

After completing a brief test drive, inspecting the caliper area for leaks helps ensure that the brake hoses, banjo bolts, bleeder valves and sealing washers are all properly tightened and sealed.

Sometimes, connections may remain leak-free when the vehicle is stationary, but leaks may occur when the system warms up or pressure increases during braking.

Checking the area for wet spots, fluid drips, or damp hoses helps you detect any problems early, before they affect braking performance or cause air to re-enter the system.

4. Monitoring Braking Performance for the First Few Miles

Monitoring braking performance for the first few miles helps you ensure that the new caliper, brake pads and rotor are adjusting smoothly.

During this time, you should pay attention to any unusual sounds, vibrations, or changes in pedal feel.

It’s normal for new pads or calipers to feel a little different initially, but braking should soon become even and smooth.

Monitoring performance over several miles confirms that the system is stable, the calipers are functioning properly and the brakes will remain reliable during daily driving.

Conclusion – How to Replace Brake Caliper

Yes, it is true that when you actually understand fully that how a caliper actually works and why every bolt and drop of fluid matters to it, then you can easily get all the things and processes and will be able to regain the strength and stability it was designed for.

Therefore, by identifying the symptoms of a malfunction, gathering the right tools and carefully following each installation and bleeding step, you can restore hydraulic pressure and mechanical grip, allowing your vehicle to stop smoothly and predictably.

A properly installed caliper ensures that the brake pads remain in even contact with the rotor, preventing uneven wear, preventing fluid leaks and maintaining a firm brake pedal under all driving conditions.

This repair also helps protect other brake system components, such as the master cylinder, brake hoses and ABS, from the stress caused by a faulty caliper.

Completing the job with a careful test drive, leak inspection and constant monitoring ensures that the brake system functions correctly and provides reliable braking performance for thousands of miles.

With patience, precision and the right information, replacing a brake caliper becomes not only easy but also a highly rewarding way to increase your vehicle’s safety and restore braking confidence.

As well as, you can ask the unsolved questions in the comment section below this guide.

Frequently Asked Questions

Q1. How do I know if my brake caliper is bad?

Answer: Brake calipers usually give obvious signs when they’re starting to wear out. You might feel the car pull to one side when braking, meaning one caliper is gripping harder than the other. You might notice uneven wear on the brake pads because the stuck caliper isn’t disengaging properly. Sometimes, you might notice brake fluid leaking near the wheel, which is a clear sign that the caliper piston or seal is worn out. A burning smell or overheating of the wheel after driving also indicates that the caliper is sticking and causing constant friction. If the brake pedal feels soft or spongy, it could mean air has entered the system due to a leaking caliper. Any of these symptoms should be checked immediately, as a bad caliper can affect the vehicle’s braking safety.

Q2. Is it safe to drive with a bad brake caliper?

Answer: Driving with a bad brake caliper is unsafe because it reduces braking power and makes the vehicle unpredictable. A stuck caliper can press the brake pads against the rotor, generating heat, damaging the rotor and increasing stopping distance. A leaking caliper can let air into the brake lines, causing the pedal to soften and pressure to decrease. This can cause delayed braking or even complete brake failure. Although the car continues to run, there’s a greater risk of losing control during a sudden stop, so it’s always better to have a bad caliper repaired or replaced as soon as possible.

Q3. How long does it take to replace a brake caliper?

Answer: For someone familiar with basic tools, replacing a brake caliper typically takes about one to two hours. This includes removing the wheel, disconnecting the brake hose, replacing the caliper, installing new brake pads if needed, bleeding the brake system and taking a test drive. A professional mechanic can complete this job quickly, sometimes within 30 to 45 minutes, as they have the right equipment and experience. If the parts are rusted, the brake hose is clogged, or the system needs further bleeding, the time may increase.

Q4. Should I replace both brake calipers at once?

Answer: Replacing both calipers isn’t necessary, but it’s often recommended for uniform braking performance. When one caliper is new and the other is old, braking force can become unbalanced because the old caliper doesn’t operate as smoothly. Replacing both calipers ensures the brake pads, pistons and sliders work evenly, maintaining smooth and consistent braking. However, if only one caliper is leaking or sticking, you can replace only that one, provided the other caliper is inspected and confirmed to be in good condition.

Q5. Do I need to bleed the brakes after replacing a caliper?

Answer: Yes, it’s important to bleed the brakes every time you remove a caliper or disconnect a brake hose. Replacing a caliper introduces air into the brake lines, reducing hydraulic pressure because it compresses easily. Bleeding removes this trapped air and makes the brake pedal firmer. Without bleeding, the brakes may feel soft or rough, specially during sudden stops. Bleeding ensures that the lines contain only brake fluid, which is essential for strong and consistent braking.

Q6. Can I replace a brake caliper at home?

Answer: Yes, if you have basic mechanical skills and the right tools, such as a wrench, jack, jack stands and brake bleeding equipment, you can replace a brake caliper at home. The process involves removing the wheel, disconnecting the brake hose, replacing the caliper, installing the pads, tightening the bolts and bleeding the system. While it’s a simple task, it requires patience and attention to details such as torque settings and fluid levels. If you’re unsure or don’t have the right tools, a professional mechanic is a safe bet.

Q7. How much do new brake calipers cost?

Answer: The cost of new brake calipers depends on the type of vehicle and the quality of the replacement part. Most standard passenger cars cost between $40 and $150 per caliper. Premium, heavy-duty, or performance calipers can cost $200 or more. Labor costs vary, but a mechanic can charge $80 to $150 to install a caliper. The total replacement cost for most cars typically ranges from $150 to $300.

Q8. What if a brake caliper gets stuck?

Answer: A stuck brake caliper keeps the brake pads pressed against the rotor even when you’re not pressing the brake pedal. This causes constant friction, which generates heat, warps the rotor, wears out the pads faster and reduces fuel efficiency. You may smell a burning smell, hear a grinding noise, or the car may slow down on its own. Over time, this can damage the wheel bearings and other components near the overheating part. A stuck caliper should be repaired immediately to avoid major damage and safety risks.

References:

[1] Corrosion Stiction in Automotive Braking Systems

https://air.uniud.it/retrieve/9855ea0d-d6e9-4f5b-a805-3eae252a169a/materials-16-03710-v2.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.