Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

It is true that even a small leak in the power steering pump that can actually drop system pressure instantly, that makes your vehicle very harder to control or it can lead to some costly steering rack damage as well.

Literally, a power steering pump is very important parts of your car’s steering system as it creates the hydraulic pressure that helps you to turn the wheel with the almost no effort.

As well as, in most of the vehicles: the pump moves around 1,000 to 1,500 psi of hydraulic pressure, so even a small failure in that can make the steering wheel feel really stiff, jerky or noisy as hell.

And, there’s a studies in automotive maintenance that shows that over 70% of the steering-related problems are actually linked to low fluid levels, worn hoses or a failing pump as well: and all of which can be easily prevented when you timely replace them.,

So, whenever a pump starts to fail, then it often produces whining sounds, leaks or you can actually feel difficulty in steering at the low speeds: which is the clear signs that it cannot maintain the pressure that your steering system actually needs.

Now, this is the guide that shows How to Replace Power Steering Pump, so that you can easily restore that smooth and safe steering function.

Tools

| Tool / Material | Simple Description | Why It Is Needed |

|---|---|---|

| Socket Set and Wrenches | A set of metal tools used to loosen or tighten bolts. | Removing and installing the bolts that hold the power steering pump. |

| Screwdrivers | Basic hand tools with flat or cross tips. | For removing small screws and hose clamps. |

| Pulley Removal Tool / Power Steering Pulley Puller | A special tool that safely removes the pulley from the old pump. | This is needed because on many new pumps the pulley has to be removed and reused. |

| Drain Pan | A shallow container for holding liquids. | Collecting old power steering fluid when draining the system. |

| Replacement Power Steering Pump | A new pump that will replace the old, worn out pump. | This is the main part to be installed to restore proper steering pressure. |

| New Power Steering Fluid | Fresh hydraulic fluid as recommended by the vehicle manufacturer. | Filling the system after installation and ensuring the pump operates smoothly. |

| Safety Gloves and Goggles | Protective gear for your hands and eyes. | To protect against sharp edges, hot parts and splashes of liquids. |

| Torque Wrench (Recommended) | A wrench that tightens bolts to a specific force. | This ensures that the bolts are tightened correctly without damaging the parts. |

What are The Safety Precautions That Needs to Be Done

1. Park the vehicle on level ground and engage the parking brake.

Ensuring your car is parked on a flat, level surface is the first and most crucial safety step as it prevents any movement while you work.

A secure and stable position keeps the vehicle balanced, reducing the risk of slipping or shifting while lifting components or applying force.

Engaging the parking brake adds another layer of safety by locking the rear wheels, providing you with a stable and controlled workspace during repairs.

2. Disconnect the battery.

Disconnecting the battery is essential as it prevents accidental electrical sparks or short circuits when working near metal tools, wires and moving engine parts.

Even a small electrical surge can damage sensors, power steering components, or the vehicle’s electronic systems.

By removing the negative battery cable, you eliminate the risk of unexpected cranking, electric shocks, or damage to sensitive wiring around the steering assembly.

3. Allow the engine to cool down.

Allowing the engine to cool down prevents burns, heat-related injuries and damage to surrounding components.

The power steering system is located near belts, hoses and metal surfaces that can become extremely hot.

Working while the engine is still hot can also lead to unexpected surges in fluid pressure.

Allowing the engine to cool ensures that metal parts, pulleys and hydraulic lines are at a safe temperature before beginning any repairs or inspections.

4. Wear appropriate safety gear.

Wearing appropriate safety gear protects you from sharp edges, slipping tools and exposure to hydraulic fluid.

Safety gloves protect your hands from cuts, burns and chemical irritation, while safety goggles protect your eyes from fluid splashes and falling debris.

Because power steering fluid is slippery and can irritate the skin, wearing the right gear helps you work with better grip, comfort and confidence during the repair process.

5. Keep your workspace clean to prevent contamination of the hydraulic components

A clean workspace is crucial because the power steering system relies on clean hydraulic fluid to function properly.

Dirt, dust, or small metal particles can cause serious internal damage if they get into the pump or hoses.

Keeping your tools, parts and surrounding area clean maintains the purity of the fluid and prevents blockages within the system.

A clean workspace also helps you stay organized, minimize errors and ensure that all parts fit correctly during reassembly.

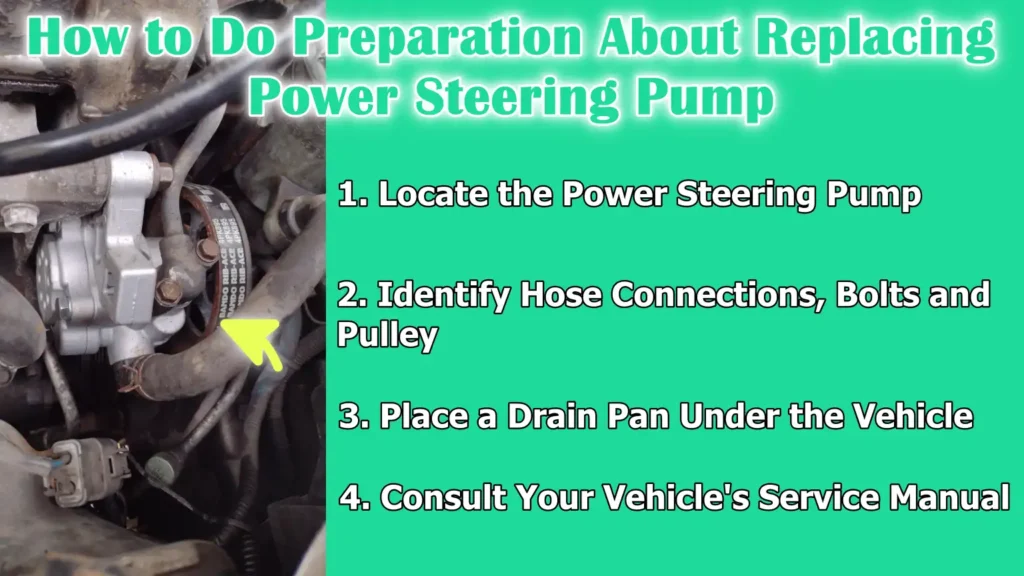

How to Do Preparation About Replacing Power Steering Pump

1. Locate the Power Steering Pump

Before you begin, locate the power steering pump in your vehicle’s engine bay.

In most vehicles, the pump is located at the front of the engine and is driven by the serpentine belt or a separate accessory belt.

Identifying its exact location will give you an idea of how much working space you have and will make the entire repair easier and safer.

This simple step also allows you to inspect surrounding components, such as the belts, fluid reservoir and nearby hoses.

2. Identify Hose Connections, Bolts and Pulley

Once you’ve located the pump, take a moment to identify all the hose connections, mounting bolts and the pulley attached to it.

The pump typically has a high-pressure line that carries fluid to the steering rack and a low-pressure return hose.

Identifying these beforehand helps prevent confusion during removal and reduces the likelihood of mixing them up.

This also gives you an opportunity to check for any damaged seals, cracked hoses, or loose mounting bolts that may need attention during the repair.

3. Place a Drain Pan Under the Vehicle

Placing a drain pan under the vehicle is a crucial step because power steering fluid will leak once the hoses are disconnected.

This fluid is oily and can stain your driveway or garage floor.

A proper drain pan will safely collect the used fluid and keep your workspace clean, preventing spills and messes.

It also allows you to properly dispose of the old fluid, as power steering fluid should never be poured down a drain or into the sewer system.

4. Consult Your Vehicle’s Service Manual

Consulting the service manual for your specific vehicle model will provide you with accurate information regarding bolt locations, torque specifications, fluid type and other important details.

The layout of each car may be slightly different and the manual will help you understand what a good quality model should look like.

The manual may also include diagrams and suggested steps that save you time and prevent damage to the parts.

Start with a clear plan before attempting to understand these details and you’ll have everything you need to guide your entire team.

How to Replace Power Steering Pump – Complete Guide

1. Drain the Power Steering Fluid

Draining the power steering fluid is the first step as it prevents spills and minimizes mess when removing the pump.

To begin, loosen the clamp on the return hose to allow the fluid to drain easily, as the return hose typically carries the old fluid back to the reservoir.

Once the clamp is loose, allow the fluid to drain completely into a pan placed beneath the vehicle to prevent spills on the ground.

If the reservoir is obstructing access or hindering proper drainage, removing it can simplify the process and help ensure all the old fluid is removed.

This step is crucial as residual fluid can contaminate the new pump or cause pressure issues after installation.

2. Remove the Belt or Serpentine Belt

After the fluid has been drained from the system, the next step is to remove the belt or serpentine belt that drives the power steering pump.

First, locate the belt tensioner, which is a spring-loaded pulley designed to keep the belt taut.

Using a wrench on the tensioner, you can release the tension and gently move it to the side, allowing the belt to become loose enough to be removed.

Once the tension is released, remove the belt from the pump pulley and carefully set it aside, away from the work area.

Removing the belt prevents damage to it and provides clear access to the bolts, hoses and pump assembly.

3. Disconnect the Hoses

With the belt removed, you can now disconnect the hoses connected to the power steering pump.

Begin by disconnecting the high-pressure line, which typically has a threaded fitting designed to handle the high hydraulic pressure generated by the pump.

Next, remove the low-pressure return line, which is usually secured with a clamp.

After disconnecting both lines, it’s crucial to cap or plug them to prevent dirt, dust, or moisture from entering the system.

Clean hydraulic lines help maintain proper fluid flow and protect the new pump from contamination damage.

4. Remove the Mounting Bolts

Next, remove the bolts that hold the power steering pump in place.

Support the pump with one hand while loosening the bolts to prevent it from falling.

Loosen each bolt in a specific sequence to keep the pump balanced and prevent stress on the mounting bracket.

Once all the bolts are removed, gently lift the pump out of the engine bay.

Carefully removing the pump helps prevent damage to surrounding components such as hoses, brackets, or the serpentine belt system.

5. Remove the Pulley – If reusing

If the pulley from the old pump is to be reused, it’s essential to remove it correctly to prevent bending or damage.

Use a pulley removal tool specifically designed for power steering pulleys, as other tools can apply uneven pressure and warp the pulley.

Securely attach the tool and slowly rotate it until the pulley separates from the old pump.

After removal, inspect the pulley for signs of wear, such as cracks, wobbling, or rough edges.

A worn pulley should not be reused, as it can cause belt noise, uneven rotation, or damage to the new pump.

How to Install the New Power Steering Pump

1. Attach the Pulley to the New Pump

Attaching the pulley to the new power steering pump is an important step, as the pulley helps secure the pump to the engine belt.

To do this correctly, use a pulley puller tool rather than force it into place, as this tool applies even pressure and prevents damage to the pump shaft.

Carefully align the pulley to the pump so that it sits straight, as even slight misalignment can cause vibration, noise, or premature belt wear.

Tighten the pulley slowly until it reaches the correct seating depth specified by the manufacturer, as overtightening or undertightening can affect the pump clearance and damage the belt.

Correct and timely installation of the pulley ensures a stable, secure and long-lasting connection.

2. Install the new pump

Once the pulley is attached, place the new pump in its mounting position in the engine bay.

Ensure there are no obstructions from hoses, wiring, or other nearby components.

Loosen the mounting bolts first, as this will allow you to adjust the pump to fit snugly and align with the serpentine belt path.

Once the pump is in place, tighten each bolt evenly to avoid excessive tension on one side.

Finally, tighten the bolts to the torque specifications provided by the vehicle manufacturer, as undertightening can cause loosening and overtightening can cause damage.

3. Reconnect the hoses

Once the pump is securely mounted, reconnect the power steering hoses to ensure proper fluid circulation in the system.

Start by attaching the high-pressure line, ensuring the fittings are clean and properly tightened to prevent leaks.

Reconnect the return line, which returns fluid to the reservoir and secure it with a plastic tie to prevent air from entering the system.

Check all O-rings and seals and replace any that appear broken, flat, or worn, as these small parts prevent leaks and play a vital role in maintaining proper system integrity.

A clean, sealed connection ensures that the new pump operates smoothly and reliably.

4. Reinstall the Serpentine Belt

The final step is to reinstall the serpentine belt, which drives the new power steering pump along with other engine accessories.

Follow the diagram provided under the hood or in the service manual to ensure it runs in the correct direction.

Use the belt tensioner to loosen the belt, then place the belt on the power steering pump pulley and release the tensioner to its normal position.

Once the belt is in place, carefully check its alignment to ensure it sits properly on all pulleys without any bends or knots.

Proper alignment can prevent noise, belt wear and damage to the new pump.

Read More:

How to Refill and Bleed the System

1. Add New Power Steering Fluid

Adding new power steering fluid is a crucial step because the pump requires clean, fresh hydraulic fluid to generate the necessary pressure for smooth steering.

Initially, fill the reservoir to the “cold” or minimum mark indicated on the side, as these marks help prevent overfilling before the system is fully circulated.

It’s essential to use only the fluid recommended by the vehicle manufacturer, as different fluids have varying chemical properties, viscosity levels and additives.

Using the wrong fluid can lead to pump noise, seal damage, or reduced steering performance.

Fresh fluid also helps protect the new pump from wear, keeps internal parts lubricated and allows the system to operate at the correct pressure.

Taking the time to properly fill the reservoir lays the foundation for a safe and effective bleeding process.

2. Bleed the System

Bleeding the system is vital because trapped air can cause whining noises, jerky steering and poor hydraulic pressure.

Begin the process with the engine off by slowly turning the steering wheel from lock to lock, allowing the fluid to circulate through the lines without stressing the pump.

After a few turns, check the fluid level in the reservoir, as the system will typically begin drawing fluid into the pump, cylinder and hoses.

Next, start the engine and repeat the lock-to-lock steering motion, allowing the fluid to circulate under normal hydraulic pressure.

Carefully observe the reservoir for bubbles, as bubbles indicate that there is still air trapped in the system.

Continue the bleeding process until the fluid is completely smooth and free of foam or bubbles, which indicates that all the air has been removed and the pump can operate at full efficiency.

A properly bled system protects the new pump, reduces noise and ensures smooth, consistent steering during everyday driving.

How to Perform Final Inspection

1. Check for Leaks Around Hoses and Pump

Checking for leaks is a crucial final step, as even a small fluid leak can compromise documentation and lead to system failure.

After repressurizing and bleeding the system, carefully inspect all hose connections, fittings and the area around the pump to ensure there are no fluid leaks.

Power plant systems operate at high pressures and leaks are often caused by faulty O-rings, loose fittings, or improperly installed hoses.

Early detection of leaks can prevent damage to the new pump and ensure safe, smooth operation.

A clean, dry surface around the components indicates that the system is properly sealed.

2. Check Belt Alignment and Tension

Checking belt alignment and tension is essential to ensure the serpentine belt is properly installed, as misalignment can cause noise, vibration, or premature belt wear.

Ensure the belt is seated correctly on all pulleys and that there are no twists or gaps.

Correct tension is also critical; a loose belt can slip and reduce pump lifespan, while a belt that is too tight can put excessive stress on the bearings and shorten their lifespan.

Proper belt alignment and tension ensure the power plant system operates efficiently and minimizes the risk of future problems.

3. Listen for Unusual Noises

Listening for unusual noises can quickly indicate whether the pump and system are functioning correctly.

Sounds such as whining, groaning, or grinding are signs of trapped air, low fluid levels, misaligned pulleys, or a failing pump.

When the system is operating correctly, the sound should be smooth and quiet at all speeds and operating angles.

Paying attention to early signs of noise can help you fix minor problems before they become major and expensive.

4. Checking Fluid Levels After Driving for a While

Fluid levels should be checked after driving for a while because normal driving allows air to be purged from the system due to fluid circulation.

The fluid level usually stabilizes after the pump has been running for a few minutes and the steering wheel has been turned several times.

Checking the reservoir at this stage ensures that the system has the correct amount of fluid, preventing the pump from running dry and reducing wear and tear.

A properly filled reservoir contributes to longer component life, smoother operation and lasting repair control.

What are The Common Mistakes That You Should Avoid

1. Overtightening the Pulley

Overtightening the pulley is a common mistake that can significantly damage a new power steering pump.

When excessive force is applied during installation, the pulley can be pressed too far onto the pump shaft, leading to misalignment, increased friction, or even pump failure.

A pulley that is overtightened beyond the manufacturer’s specifications can also cause premature wear of the serpentine belt or slippage during operation.

Following the correct torque guidelines and using the proper installation tools ensures the pulley is seated at the correct depth, allowing the pump to rotate freely and operate at its intended efficiency.

2. Using the Wrong Type of Fluid

Using the wrong type of fluid is another mistake that can quickly damage a power steering system.

Power steering fluids are formulated with different additives, lubrication properties and chemical compositions and using a fluid not approved for your vehicle can lead to seal degradation, reduced lubrication, or foaming within the system.

These issues can result in noisy steering, pump overheating, or complete pump failure.

Always checking the owner’s manual or reservoir cap for the correct fluid type protects internal components and ensures reliable pump operation.

3. Forgetting to Bleed the System

Forgetting to bleed the system after installing a new pump can trap air in the hydraulic lines, resulting in stiff, jerky, or noisy steering.

Air pockets reduce hydraulic pressure, preventing the pump from operating at full capacity and potentially causing a whining noise when turning the wheel.

Over time, air can enter the system, leading to uneven fluid flow and increased wear on the internal parts of the pump.

Properly bleeding the system removes these air pockets, ensuring smooth and consistent steering performance.

4. Reusing Worn Hoses or Clamps

Reusing worn hoses or clamps can lead to leaks and pressure problems shortly after installing a new pump.

Old hoses may have cracks, weak spots, or hardened rubber, making them more susceptible to failure under pressure.

Faulty clamps may not seal properly, allowing fluid leaks or air to enter the system.

These issues can result in noisy steering, reduced pump lifespan, or even sudden fluid loss while driving.

Inspecting the hoses and clamps during installation and replacing any parts showing signs of wear ensures that the power steering system remains sealed, reliable and long-lasting.

When You Should Consult to the Professional or Mechanic

As well as, there’s a documented case that shows that more than one out of five hydraulic pumps had to be returned because of the input-shaft seal leakage, also engineers traced the cause not to a bad seal, but to the subtle internal damage in the pump’s rotating assembly, so after redesigning the manufacturing process, the failure rate actually dropped under 1%, so it is an important reminder that correct installation may not always be enough if the design or build quality is actually flawed.[¹]

1. If the Pump Pulley is Jammed or Damaged

If the pulley is jammed or damaged, it’s a strong indicator that you should seek professional help, as removing or installing the pulley requires specialized tools and skills.

Forcing a bent, broken, or seized pulley off an old pump, even with the correct removal tool, can damage the pump shaft or result in improper installation of the new pulley.

Professional mechanics have specialized hydraulic and press tools that safely remove tightly seized pulleys without damaging surrounding components.

Because the pulley must rotate perfectly straight for the steering system to function correctly, any mistakes during removal or installation can lead to belt noise, pump failure, or improper steering operation.

2. If the Hydraulic Lines are Corroded or Leaking Excessively

Corroded or excessively leaking hydraulic lines should also be addressed by a professional, as these lines contain high-pressure fluid that must remain completely sealed.

Corrosion weakens the metal lines and can lead to cracks or sudden ruptures, potentially causing a sudden loss of power steering assist while driving.

Replacing these lines often requires precise bending, flaring, or specialized fittings to ensure leak-free connections.

Professionals have the correct tools and experience to safely repair or replace hydraulic lines according to factory specifications, preventing future leaks and maintaining proper hydraulic pressure.

3. If the Steering Remains Stiff After Installation

If your steering remains stiff after installing a new pump and bleeding the system, it could indicate a larger problem that requires a trained technician.

Persistent tightness in the steering wheel can be caused by trapped air that is difficult to remove, a faulty steering rack, blocked hoses, or incorrect pump pressure output.

A mechanic can perform a pressure test, inspect the steering rack and identify underlying problems that may not be apparent with just a pump replacement.

It’s crucial to address these issues promptly, as driving with tight steering can be unsafe and can also damage other parts of the system.

Conclusion – How to Replace Power Steering Pump

It is true that the power steering pump really affects everyday driving, which is why installation should be correct and it also helps you to maintain long-term vehicle health as well.

The power steering pump helps maintain the correct hydraulic pressure within the system, allowing for easy turning of the steering wheel.

When this pump begins to fail, the steering becomes stiff, noisy, or unpredictable, making driving unsafe.

By carefully following the steps, using the correct tools, checking for leaks and refilling with the proper type of power steering fluid, you can restore steering performance and prevent unnecessary stress on other components of the steering system.

It’s crucial to work systematically, double-check every connection and listen for any unusual noises after the job is complete.

Proper installation not only improves the vehicle’s handling but also prevents costly repairs in the future.

It’s equally important to know when to stop and seek professional help, as some problems, such as severe hydraulic line damage or a seized pulley, require the expertise of a trained mechanic.

Overall, this repair empowers you to maintain your vehicle yourself and ensures your steering system remains reliable and smooth for many miles to come.

Now, you can comment down below for more information about this guide.

Frequently Asked Questions

Q1. What are the signs of a bad power steering pump?

Answer: A failing power steering pump typically exhibits clear warning signs, such as a whining or groaning noise when turning the steering wheel, stiff or heavy steering, fluid leaks under the front of the car, or a burning smell due to low or leaking fluid. Sometimes the steering may feel jerky or erratic because the pump isn’t maintaining consistent pressure. If these symptoms appear, it’s best to have the pump checked immediately to prevent damage to other steering components.

Q2. Is replacing a power steering pump difficult for a novice?

Answer: Replacing a power steering pump is manageable for anyone with basic mechanical aptitude, patience and the right tools. It involves removing the old pump, transferring or reinstalling the pulley, properly connecting the hoses and filling the system with the correct fluid. The most challenging part for novices is usually removing and installing the pulley, which requires a special tool. As long as you carefully follow the instructions and take your time, it can be safely done at home.

Q3. How long does it take to replace a power steering pump?

Answer: This job typically takes one to three hours, depending on your vehicle’s design, your experience level and how easily the pulley or bolts come off. Some vehicles have easily accessible pumps, while others require removing additional components like engine covers or serpentine belt tensioners. If it’s your first time, giving yourself extra time helps prevent mistakes and makes the repair less stressful.

Q4. Does the power steering system need to be bled after installing a new pump?

Answer: Yes, bleeding the system is crucial as it removes trapped air from the hydraulic lines. Air bubbles in the system can cause noise, jerky steering, or damage to the new pump. Bleeding is typically performed after filling the fluid reservoir to the correct level and turning the steering wheel from lock to lock. Several turns may be necessary to remove all the air. Skipping this step is one of the most common reasons for premature failure of a new pump.

Q5. What type of power steering fluid should I use after replacing the pump?

Answer: The correct fluid type depends on your vehicle’s make and model specifications. Some cars use standard power steering fluid, while others require ATF (Automatic Transmission Fluid) or synthetic hydraulic fluid. Using the wrong fluid can damage seals, cause pump noise, or result in poor steering response. Always consult your owner’s manual or the label under the hood to determine the correct fluid for your vehicle.

Q6. Why is the pulley so important when replacing a power steering pump?

Answer: The pulley is responsible for driving the pump using the serpentine or accessory belt. If the pulley is not properly aligned or is overtightened, it can damage the belt or cause premature pump failure. A pulley puller tool is necessary to safely remove and install the pulley without bending it. Proper alignment ensures the belt runs smoothly and the pump rotates at the correct speed.

Q7. What should I do if the steering still feels stiff after replacing the pump?

Answer: If the steering is still stiff, you may need to bleed the system again, as air may be trapped in the lines. You should also check the belt tension, fluid level and inspect the hydraulic hoses for leaks or blockages. In some cases, the problem might not be the pump but the steering rack, which can make steering heavy if it’s worn or jammed. If the problem persists after checking everything, it’s best to have the system inspected by a professional.

Q8. Can I drive with a bad power steering pump?

Answer: Driving with a faulty pump is dangerous because you could suddenly lose power assist, making steering very difficult and unsafe, specially at low speeds or when making sharp turns. A faulty pump can also overheat and leak fluid, potentially causing further damage to the belts and hoses. If you notice symptoms of a bad pump, it’s better to get it repaired rather than continuing to drive and risking a breakdown.

Q9. Do I need to replace the hoses or clamps when replacing the pump?

Answer: It’s not always necessary, but it’s advisable to carefully inspect all hoses and clamps. If they appear cracked, swollen, loose, or weak, it’s a good idea to replace them at the same time. Old hoses can leak under pressure and damage the new pump. Installing a new pump with old, weak hoses can shorten the lifespan of the repair.

References:

[1] Mitigating High Steering Effort in Power Steering Pumps through Manufacturing Process Improvement

https://www.citedrive.com/en/discovery/mitigating-high-steering-effort-in-power-steering-pumps-through-manufacturing-process-improvement/

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.