Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Did you know that?: most of the time speedometer problems starts with a bad sensor or loose wire and it gets worsen if you ignore it there.

And, a car speedometer is really important instruments on the vehicle’s dashbaord, as it literally tells the driver how fast the car is actually travelling in real time.

As well as, there’s road safety agencies that tells that: driving without having the knowledge of your correct speed can increase the risk of speeding violations, accidents and even you can loss the vehicle control as well, which is really scary thing in heavy traffic or poor weather conditions.

Now-a-days, modern cars uses electronic speed sensors which is directly connected to the transmission and engine control unit (ECU); other than this the older vehicles relies on the mechanical cables which is linked to the gearbox.

So, whenever any of these components fails like: it can be faulty vehicle speed sensor, damaged wiring, blown fuse or instrument cluster problems; then literally speedometer can stop working as well, that’s how it leads to showing you incorrect readings or behaves erratically.

That’s why, we have come up with this guide on How to Fix a Car Speedometer, so that you can diagnose them easily and restore your vehicle’s accurate speed readings to stay legal in the road as well.

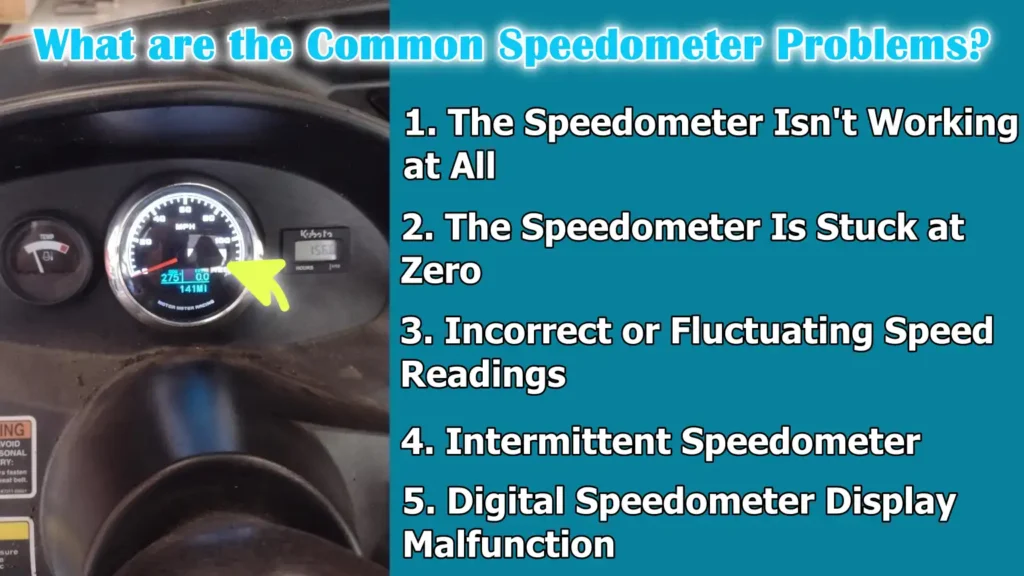

What are the Common Speedometer Problems?

1. The Speedometer Isn’t Working at All

When the speedometer doesn’t work at all, it usually means that the system that sends speed information to the dashboard has completely failed.

In modern vehicles, this is often caused by a faulty vehicle speed sensor, a blown fuse, faulty wiring, or a problem with the instrument cluster itself.

In older cars with mechanical speedometers, the speedometer cable may be broken or disconnected.

When the speedometer fails completely, drivers can’t tell how fast they’re going, increasing the risk of speeding, unsafe driving and legal fines.

In many cases, this problem also affects other systems, such as cruise control and automatic transmission shifting, as they rely on the same speed data.

2. The Speedometer Is Stuck at Zero

When the speedometer remains stuck at zero even after the vehicle is in motion, this is a very common problem, specially with electronic speedometer systems.

This typically occurs when the vehicle speed sensor stops sending signals to the engine control unit or dashboard.

Dirt buildup, a faulty sensor, broken wiring, or loose connectors are common causes.

In some vehicles, a faulty gear sensor inside the transmission can also prevent speed data from being generated.

Although the car may run normally, the lack of speed information can cause delayed gear shifts, cruise control failure and improper fuel management in modern vehicles.

3. Incorrect or Fluctuating Speed Readings

Incorrect or fluctuating speed readings often indicate intermittent signal transmission rather than a complete failure.

This problem may be caused by a partially faulty speed sensor, poor wiring, weak electrical connections, or a tire size change that hasn’t been recalibrated to the vehicle’s system.

Research in automotive diagnostics shows that even minor disruptions in the electrical signal can cause erratic fluctuations in the speedometer needle or digital reading.

This can confuse drivers, make it difficult to maintain a consistent speed and increase the risk of unintentionally speeding or engaging in unsafe driving behavior.

4. Intermittent Speedometer

Intermittent speedometers may sometimes work correctly and other times malfunction, often making the problem difficult to diagnose.

This problem is usually associated with loose wiring connections, broken solder joints within the instrument cluster, or sensors failing when exposed to heat or vibration.

As the vehicle warms up or is driven on rough roads, electrical connections may temporarily break and reconnect.

Intermittent speedometer problems are early warning signs that should not be ignored, as they often lead to complete failure if left uncorrected.

5. Digital Speedometer Display Malfunction

Digital speedometer malfunctions are more common in modern vehicles with electronic dashboards and digital displays.

These malfunctions may include a blank screen, frozen numbers, dim lights, or delayed speed updates.

Common causes include software errors, a faulty display module, a bad circuit board, or power supply problems within the instrument cluster.

In some cases, a simple system reset or software update may resolve the issue, while in others, the cluster may need to be repaired or replaced.

Because digital speedometers are entirely electronic, even minor voltage or communication problems can prevent the display from functioning properly.

Understand, How a Car’s Speedometer Works

1. Mechanical Speedometers – Older Cars

Older cars typically used mechanical speedometers, which operated using simple physical movement rather than electronics.

In this system, a flexible metal cable is connected to the car’s transmission.

As the car moves, the transmission rotates this cable and the speed of rotation increases with the car’s speed.

Inside the dashboard, the rotating cable spins a magnet that pulls on a needle on the speed dial.

The faster the cable spins, the higher the speed displayed on the gauge.

Because this system relies on moving parts, it can wear out over time.

Common problems include broken cables, dry or kinked cables and worn gears, which often cause the speedometer to stop working or give noisy and inaccurate readings.

2. Electronic Speedometers – Modern Cars

Modern cars use electronic speedometers that rely on sensors and electrical signals instead of mechanical cables.

In this system, the car’s speed is measured electronically and displayed on the dashboard as a needle or digital numbers.

Electronic speedometers are more accurate and reliable because they have fewer moving parts.

They also allow for sharing speed data with other vehicle systems such as cruise control, anti-lock braking systems and stability control.

However, because these systems rely on electronics, problems such as sensor failure, faulty wiring, or software glitches can lead to inaccurate speed readings or complete speedometer failure.

3. The Role of the Vehicle Speed Sensor – VSS

The vehicle speed sensor, commonly referred to as the VSS, is the main component that measures how fast the vehicle is moving.

It is typically located on the transmission or near the wheel hub, depending on the vehicle’s design.

The sensor works by detecting the rotational speed of a gear or shaft and converting that movement into an electrical signal.

This signal represents the vehicle’s speed and is sent to the car’s computer.

If the speed sensor becomes dirty, damaged, or stops working altogether, the speedometer may stop working, display an incorrect speed, or behave erratically.

A faulty VSS can also affect transmission shifting, fuel efficiency and the operation of the cruise control.

4. The Relationship Between the Speedometer, ECU and Transmission

In modern cars, the speedometer doesn’t operate in isolation.

The transmission generates the physical movement, the vehicle speed sensor measures that movement and the engine control unit, or ECU, processes the data.

The ECU receives speed information from the sensor, verifies its accuracy and then sends it to the speedometer display.

The ECU also uses this speed data to control gear shifting, engine performance and safety systems.

If there’s a problem anywhere in this communication chain such as: a faulty sensor, damaged wiring, or a malfunction in the ECU, then the speedometer may display incorrect information or stop working entirely.

This close connection explains why speedometer problems are often accompanied by transmission or engine performance issues.

Tools

| Item / Topic | Purpose and Helpful Details |

|---|---|

| OBD Scanner | An OBD scanner reads error codes from a car’s computer. It helps diagnose problems related to the speed sensor, ECU, or instrument cluster. This tool saves time by pinpointing the faulty part. |

| Multimeter | A multimeter checks the voltage, resistance and continuity of wires. It helps confirm whether the speed sensor or wiring is working correctly. This tool is essential for finding hidden electrical problems. |

| Screwdrivers | A screwdriver will be needed to remove the dashboard panel and sensor cover. This allows safe access to the instrument cluster and wiring. Using the correct size screwdriver prevents damage to the screws and panel. |

| Safety Gloves | Gloves protect your hands from sharp edges and hot surfaces. They also reduce the risk of electric shock. Wearing gloves improves grip and control while working. |

| Safety Steps Before Repair | Always park the vehicle on a level surface and engage the parking brake. Turn off the engine and remove the key before starting any work. Allow the engine to cool down to avoid burns. |

| Battery Disconnection | Disconnect the battery when working on electrical parts or the dashboard. This prevents short circuits and protects the electronic components. Always remove the negative terminal first. |

| Vehicle Service Manual | A service manual provides correct repair procedures and wiring diagrams. It helps in identifying sensor locations and torque values. Using the manual reduces errors and saves time. |

How to Diagnose Speedometer Problems

1. Checking Dashboard Warning Lights

Dashboard warning lights are often the first indication of a speedometer problem.

When the check engine light, ABS light, or traction control light illuminates, it can indicate a malfunction related to the vehicle speed sensor or communication between the ECU and the instrument cluster.

Modern vehicles use speed data to control numerous systems, so even a minor issue with the speed signal can trigger warning lights.

Paying attention to these lights helps drivers detect speedometer-related problems early, before they lead to more significant engine or transmission issues.

2. Scanning the Vehicle for Error Codes

Scanning the vehicle for error codes is one of the most accurate ways to diagnose speedometer problems in modern cars.

An OBD scanner connects to the car’s computer and reads stored fault codes related to the speed sensor, signal loss, or instrument cluster failure.

These codes provide clear indications of which component is malfunctioning, saving time and preventing unnecessary parts replacements.

Even when the speedometer appears to be working normally, stored error codes can reveal hidden or intermittent problems.

3. Checking Fuses Related to the Instrument Cluster

Fuses protect the vehicle’s electrical system from damage caused by power surges or short circuits.

A blown fuse connected to the instrument cluster can cause the speedometer to stop working entirely or behave erratically.

Checking the fuses is a simple yet crucial step, as blown fuses are common and easy to fix.

Replacing a blown fuse with one of the correct rating can sometimes instantly resolve the speedometer problem without any further repairs.

4. Visual Inspection of Wiring and Connectors

A visual inspection of the wiring and connectors helps identify physical problems that diagnostic tools may not immediately detect.

Loose connectors, damaged wires, corrosion, or melted insulation can disrupt the speed signal traveling from the sensor to the ECU and speedometer.

These problems are often caused by heat, moisture, vibration, or rodent damage.

Carefully inspecting the wiring harnesses and connections can help pinpoint the root cause of speedometer failure and prevent future electrical issues.

How to Fix Mechanical Speedometer Problems

1. Checking the Speedometer Cable

The speedometer cable is the main component that transmits motion from the transmission to the speedometer in older vehicles.

Over time, this cable can wear out, loosen, or kink due to heat and vibration.

Checking the cable involves inspecting both ends, where it connects to the transmission and the back of the speedometer.

A loose or damaged cable can cause the needle to fluctuate, make clicking noises, or stop working altogether.

Timely inspection can prevent complete cable failure and sudden loss of speed readings.

2. Replacing a Damaged or Broken Cable

When the speedometer cable breaks or becomes excessively worn, replacement is the only reliable solution.

A broken cable typically causes the speedometer to stop working completely, even if the car is running normally.

Replacing the cable restores smooth rotation and accurate speed display.

Proper installation of the new cable and avoiding sharp bends are crucial, as incorrect installation can shorten its lifespan and lead to recurring malfunctions.

3. Checking the Transmission Gear Connection

Mechanical speedometers rely on a small gear inside the transmission to drive the speedometer cable.

If this gear is worn, damaged, or dislodged, the cable will not rotate properly, resulting in inaccurate or no speed readings.

Checking the transmission gear connection ensures that motion is being transmitted correctly from the transmission to the cable.

This step is particularly important in older vehicles where plastic gears can wear down over time due to heat and friction.

4. Lubricating or Adjusting the Speedometer Cable

Proper lubrication helps the speedometer cable rotate smoothly within its housing.

Without lubrication, friction increases, causing the speedometer needle to jump or make noise while driving.

Applying the correct lubricant reduces wear and extends the cable’s lifespan.

Adjusting the cable alignment can also prevent sticking and uneven rotation, helping to maintain accurate and stable speed readings while driving.

How to Fix Electronic Speedometer Problems

1. Locating and Inspecting the Vehicle Speed Sensor – VSS

The vehicle speed sensor is the main component that measures how fast the car is going and sends this information to the car’s computer and speedometer.

It’s typically located on the transmission or near the wheel hub, depending on the vehicle’s design.

Inspecting the sensor involves checking for dirt buildup, physical damage, or loose mounting.

Because the sensor is exposed to heat, moisture and road debris, it can fail over time.

A faulty or loose sensor can cause the speedometer to stop working, display incorrect speeds, or behave erratically.

2. Cleaning or Replacing a Faulty Speed Sensor

Dirt, metal particles and oil residue can accumulate on the tip of the speed sensor and interfere with its ability to accurately read speed.

Cleaning the sensor with a suitable electrical cleaner can sometimes restore normal operation.

If the sensor is internally damaged or defective, replacement is necessary.

Replacing a faulty speed sensor often fixes not only the speedometer but also other related issues such as gear shifting problems, non-functioning cruise control and warning lights on the dashboard.

3. Checking the Wiring Harness and Connectors

Electronic speedometers rely on clean and stable electrical signals.

The wiring harness and connectors carry the speed data from the sensor to the ECU and instrument cluster.

Over time, these wires can become loose, frayed, or corroded due to heat, vibration, or moisture.

Inspecting the wiring helps identify broken or damaged connections that can disrupt the speed signal.

Repairing damaged wires or securing loose connectors can restore proper speedometer function without requiring the replacement of larger components.

4. Resetting the ECU After Repair

After repairing or replacing speedometer-related components, resetting the engine control unit (ECU) helps the system relearn the correct speed data.

The ECU stores error codes and temporary data that can affect performance even after the problem is fixed.

Resetting clears these stored errors and allows the vehicle to operate with updated sensor information.

In many cases, a simple reset restores normal speedometer operation and turns off any associated warning lights.

How to Solve Instrument Cluster Problems

1. Diagnosing a Faulty Instrument Cluster

The instrument cluster is the panel on the dashboard that displays the speedometer and other essential gauges.

When the cluster malfunctions, the speedometer may stop working, stick, flicker, or display incorrect readings, even if the vehicle’s speed sensor is functioning correctly.

Diagnosing a cluster problem involves checking if other gauges or warning lights are also behaving erratically.

If multiple displays fail simultaneously, it usually points to a cluster problem rather than a sensor issue.

Electrical testing and scan tool data help confirm that the cluster is receiving speed information but is unable to display it correctly.

2. Repairing Loose Solder Joints

Inside the instrument cluster are circuit boards containing small solder joints that connect the electronic components.

Over time, heat and vibration can cause these joints to crack or become loose, leading to intermittent or complete speedometer failure.

Loose solder joints often cause problems that come and go, such as gauges working sometimes and failing at other times.

Carefully resoldering these connections restores proper electrical flow and often fixes the problem without requiring the replacement of the entire cluster.

This repair requires precision but can significantly extend the life of the cluster.

3. Replacing Stepper Motors – For Analog Gauges

Analog speedometers use small stepper motors to move the needle on the speed dial.

When these motors wear out or fail, the needle may stick, move erratically, or display incorrect speeds.

In many older electronic instrument clusters, stepper motor failure is a common occurrence and a known cause of inaccurate gauge readings.

Replacing a faulty stepper motor restores smooth and accurate needle movement.

This repair is often more cost-effective than replacing the entire instrument cluster.

4. Instrument Cluster Replacement or Reprogramming

When the instrument cluster is severely damaged or internally faulty, replacement may be the only solution.

Modern clusters are often integrated with the vehicle’s ECU and safety systems, meaning they must be programmed to match the vehicle.

Reprogramming ensures correct speed readings, mileage display and system communication.

In some cases, installing a new or refurbished cluster resolves persistent speedometer problems that cannot be fixed by sensor or wiring repairs.

Proper programming is essential to maintain accurate data and legal compliance.

How to Calibrate the Speedometer After Repair

Plus, there’s study in Transportation Research Part F that shows that a “distance-speedometer” interface is designed to display the distance and the speed together and the results showed that the drivers who are using this interface actually maintained more consistent speeds and really better spacing behind the other vehicles, so that literally shows that the way speed data is presented and having the correct speed data directly affects the driver behaviour and safety, for their obvious reasons.[¹]

1. Why Calibration is Necessary

Speedometer calibration is essential to ensure that the speed displayed on the dashboard matches the vehicle’s actual road speed.

After repairs involving sensor replacement, instrument cluster work, or transmission modifications, speed data can become inaccurate if not properly calibrated.

An uncalibrated speedometer may display a speed higher or lower than the actual speed, leading to problems such as speeding violations, unsafe driving and malfunctions in systems like cruise control and automatic transmission shifting.

Calibration ensures that the vehicle’s computer correctly interprets the speed signal and displays accurate information to the driver.

2. Using Diagnostic Tools for Calibration

Modern vehicles utilize diagnostic tools to adjust and verify speedometer accuracy.

These tools connect to the vehicle’s ECU and allow technicians to compare sensor data with actual speed values.

Diagnostic calibration helps align the speed signal with the correct vehicle settings stored in the computer.

This process ensures seamless communication between the speed sensor, ECU and instrument cluster.

Proper use of diagnostic tools allows for quick correction of speedometer display errors without replacing additional parts.

3. Adjusting for Tire Size or Gear Ratio Changes

Changes in tire size or gear ratio can directly affect speedometer accuracy.

Larger tires cover more distance per rotation, causing the speedometer to display a speed lower than the actual speed, while smaller tires can cause the speedometer to display a higher speed.

Changes in gear ratios within the transmission also alter how speed signals are generated.

Adjusting the speedometer settings after these modifications ensures that the vehicle displays the correct speed.

This step is particularly important for modified vehicles and helps maintain safe and legal driving conditions.

4. Test Driving for Accuracy Verification

After calibration, it’s essential to test drive the vehicle to confirm that the speedometer is functioning correctly.

Comparing the speedometer reading to a GPS-based speed display helps verify accuracy under real-world driving conditions.

The test drive also ensures that the speed readings remain consistent at different speeds and that no warning lights illuminate.

This final check assures drivers that the repair and calibration were successful and that the vehicle is safe to drive.

When You Should Consult to the Professional

1. Signs Indicating the Need for Advanced Diagnostics

Some speedometer problems cannot be fixed with basic tools or simple checks.

When a speedometer malfunctions, specially if accompanied by multiple warning lights, sudden transmission issues, or inaccurate data on diagnostic scans, advanced testing is usually required.

These signs often indicate deeper electrical or computer-related malfunctions that necessitate professional diagnostic equipment.

Ignoring these symptoms can allow the problem to spread to other vehicle systems, making repairs even more difficult and expensive.

2. Issues Related to the ECU or CAN Bus System

Modern vehicles rely on the Engine Control Unit (ECU) and CAN bus system to share speed data between sensors, the instrument cluster and safety systems.

If communication fails within this network, the speedometer may stop working, even if all sensors are functioning correctly.

Diagnosing ECU or CAN bus problems requires specialized tools and technical expertise.

Because these systems control critical vehicle functions, professional repair is essential to avoid accidental damage or incorrect programming.

3. Estimated Repair Costs Based on the Type of Problem

Repair costs vary depending on the cause of the speedometer problem.

Simple fixes, such as replacing a speed sensor or repairing wiring, are typically inexpensive, while instrument cluster repairs or ECU-related issues are more costly.

Software programming and cluster replacement can significantly increase costs due to labor and equipment requirements.

Understanding these cost differences helps vehicle owners determine when professional service is the most appropriate option.

4. Risks of Driving with a Malfunctioning Speedometer

Driving with a malfunctioning speedometer increases the risk of speeding, traffic violations and accidents.

Without accurate speed information, drivers may unknowingly exceed legal speed limits or fail to adjust their speed according to road and weather conditions.

Inaccurate speed data can also affect transmission shifting, cruise control and stability systems, potentially leading to unsafe driving behavior.

Promptly addressing speedometer problems ensures the safety of both the driver and others on the road.

Read More:

How to Maintain the Correct Working of Speedometer

1. Regular Inspection of Sensors and Wiring

Regular inspection of speed-related sensors and wiring can catch problems before they become serious.

A vehicle’s speed sensors and their wires are exposed to heat, dirt, water and vibration, which can cause gradual damage.

Checking for loose connections, damaged insulation, or dirt buildup can prevent signal loss and inaccurate speed readings.

Early detection reduces the likelihood of sudden speedometer failure and ensures consistent vehicle performance.

2. Protecting the Electrical System from Damage

Protecting the vehicle’s electrical system is crucial for speedometer reliability.

Improper jump-starting, installing low-quality aftermarket electronics, or exposing wiring to moisture can damage sensitive components.

Electrical surges and short circuits can affect the instrument cluster, sensors and ECU.

Taking precautions when replacing the battery and performing electrical modifications helps prevent costly and avoidable speedometer problems.

3. Keeping Software Updated in Modern Vehicles

Modern vehicles rely on software to process speed data and display accurate information.

Manufacturers release software updates to fix bugs, improve accuracy and enhance system communication.

Outdated software can lead to inaccurate readings or system malfunctions, even if all hardware components are functioning correctly.

Keeping your vehicle’s software updated ensures the smooth operation of the speedometer and related safety systems.

4. Early Warning Signs to Watch For

Minor changes in speedometer behavior often precede major malfunctions.

Flickering displays, delayed speed updates, erratic needle movement, or warning lights are common early indicators.

Paying attention to these symptoms allows drivers to address problems while they are still minor.

Taking immediate action helps avoid expensive repairs and ensures safe, confident driving.

Conclusion – How to Fix a Car Speedometer

Literally, when you fix a speedometer then it is not just about showing the correct numbers and all; but it is all about restoring the trust between the you and the vehicle itself.

That’s why this guide explains, speedometer problems can stem from a variety of causes, including faulty mechanical parts, defective sensors, damaged wiring, software errors, or a malfunctioning instrument cluster.

Also, when you properly understand how the speedometer works and how each component communicates with the vehicle’s computer helps drivers identify problems quickly and avoid unnecessary repairs.

In the modern vehicles, accurate speed data is used by multiple systems, meaning that fixing the speedometer also helps maintain the overall performance of the vehicle.

Now, that’s all about this guide and you can comment down for more information related to this guide.

Frequently Asked Questions

Q1. Why does a car’s speedometer stop working?

Answer: A car’s speedometer typically stops working due to a malfunction in the speed measurement system. Common causes include a faulty vehicle speed sensor, damaged wiring, a blown fuse, or problems within the instrument cluster itself. In older vehicles, a broken or worn speedometer cable is often the main culprit. In modern cars, software glitches or communication problems between the sensor and the car’s computer can also cause the speedometer to fail.

Q2. Can I drive my car if the speedometer isn’t working?

Answer: You can drive a car with a malfunctioning speedometer, but it’s not safe and often not legal. Without knowing your correct speed, you might unknowingly drive too fast or too slow, increasing the risk of accidents and traffic fines. In modern vehicles, a faulty speedometer can also affect systems like cruise control, transmission shifting and stability control. It’s best to have the problem fixed as soon as possible.

Q3. How do I know if my vehicle speed sensor is bad?

Answer: A faulty vehicle speed sensor often causes the speedometer to stop working, display incorrect speeds, or show erratic speed readings while driving. You might also notice warning lights on the dashboard, poor gear shifting, or a non-functional cruise control. In many cars, scanning the vehicle with a diagnostic tool will reveal error codes related to speed signal problems, confirming a faulty sensor.

Q4. Is it expensive to fix a speedometer problem?

Answer: The cost of fixing a speedometer depends on the cause of the problem. Minor repairs, such as replacing a speed sensor, fuse, or damaged wiring, are usually inexpensive. Repairs involving the instrument cluster, ECU programming, or CAN bus communication can be more costly due to labor and specialized tools. Addressing the problem promptly often keeps costs down and prevents further damage.

Q5. Can a blown fuse cause the speedometer to malfunction?

Answer: Yes, a blown fuse can cause the speedometer to stop working. The instrument cluster and speed sensor circuit are protected by a fuse to prevent damage from electrical surges. If the fuse blows, the speedometer may lose power completely. Checking and replacing the fuse with the correct rating is one of the easiest and quickest troubleshooting steps.

Q6. Does changing tire size affect speedometer accuracy?

Answer: Yes, changing tire size can directly affect speedometer readings. Larger tires cover more distance per rotation, causing the speedometer to display a speed lower than the actual speed. Smaller tires can cause the speedometer to display a higher speed. After changing tire size, speedometer calibration is necessary for accurate speed readings and safe driving.

Q7. Do modern cars require speedometer recalibration after repairs?

Answer: Most modern cars require speedometer recalibration after sensor replacement, instrument cluster repair, or transmission work. The vehicle’s computer needs to correctly match the speed data with the vehicle’s settings. Without calibration, the speedometer may display incorrect readings, even if all parts are functioning. Recalibration ensures proper communication between the sensor, ECU and display.

Q8. Can speedometer problems affect transmission performance?

Answer: Yes, speedometer problems can affect transmission performance, specially in automatic vehicles. The transmission uses speed data to determine when to shift gears. Inaccurate or incomplete speed information can lead to delayed shifts, abrupt shifting, or poor fuel efficiency. Fixing speedometer problems often improves driving smoothness.

References:

[1] Visualizing distances as a function of speed: Design and evaluation of a distance-speedometer

https://www.sciencedirect.com/science/article/abs/pii/S1369847818308283

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.