Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

It is not just about the smoothness that you have to maintain with the shock absorbers, but it also keeps your tires glued to the road and that means it improves the safety and control over the vehicle.

Plus, the shock absorbers are really one of the most important but it is often overlooked parts of a vehicle’s suspension system, but it also affects the steering, braking and overall safety.

As well as, according to the National Highway Traffic Safety Administration: the worn suspension parts can increase the stopping distance by up to 20% which is very bad for the safety.

Not only this, unlike the springs which only supports the weight of the vehicle, but shock absorbers actually control the movement of the suspension and that prevent the excessive bouncing after hitting bumps or potholes.

And studies also shows that most of the shocks starts to lose their effectiveness gradually after about 50,000 miles of driving, even if they don’t show any kind of visible damage.

Additionally, it is true that bad shocks can cause uneven tire wear, that reduce the fuel efficiency and makes it difficult handling during the emergency.

Which is why, this guide is only focuses about How to Check a Shock Absorber, so that you can extend the life of your tires and suspension of course.

The Basic Symptoms of Worn Shock Absorbers

1. Uneven tire wear

One of the most common symptoms of worn shock absorbers is uneven tire wear, often called “cupping” or “scalloping.

” This happens because weak shock absorbers are unable to firmly hold the tires to the road, causing them to bounce excessively.

As a result, some parts of the tire wear out faster than others.

Studies by tire manufacturers show that vehicles with worn shock absorbers can have up to 25% less tire life, which not only costs more money to replace them but also reduces traction and safety on wet or slippery roads.

2. Nose-diving when braking

If the front of your vehicle tilts forward sharply when you brake, this is called nose-diving.

This happens because the shock absorbers are unable to control the transfer of weight when braking.

Lack of control increases stopping distance and can make sudden stops unsafe, specially at high speeds.

Automotive safety studies show that worn shock absorbers can increase stopping distance by as much as 20%, which can mean the difference between stopping safely and being hit.

3. Excessive body roll on turns

Worn shock absorbers often appear when the car leans too much on a turn.

Normally, shock absorbers keep the vehicle stable by controlling side-to-side motion, but when their effectiveness is reduced, the car feels unstable or “top heavy” during turns.

This excessive body roll not only makes driving uncomfortable, but also reduces steering precision, which can be dangerous during emergency maneuvering or at highway speeds.

In fact, poor suspension control is associated with a higher risk of rollover in vehicles with a high center of gravity, such as SUVs and trucks.

4. Longer stopping distances

Shock absorbers play a direct role in braking performance by pressing the tires firmly to the road.

When they wear out, the tires lose contact during braking, increasing stopping distances.

This problem is specially noticeable on wet or uneven surfaces, where road grip is already low.

NHTSA statistics show that vehicles with worn suspension systems have a significantly higher risk of crashing due to reduced traction during emergency stops.

This makes it clear that shock absorbers aren’t just for comfort—they’re a vital part of your braking system.

5. Abnormal sounds (rattling, rattling)

Another clear warning sign of shock absorber wear is strange noises coming from the suspension area.

Rattling, knocking, or rattling noises are often a sign that the shock absorbers or their mounting components, such as bushings or bolts, are worn or loose.

These sounds are more audible when driving on uneven, potholed or rough roads.

Ignoring them can lead to further damage not only to the shock absorbers, but also to other parts of the suspension system.

Regularly listening and checking for such sounds helps to detect problems early, avoid costly repairs and ensure safe driving.

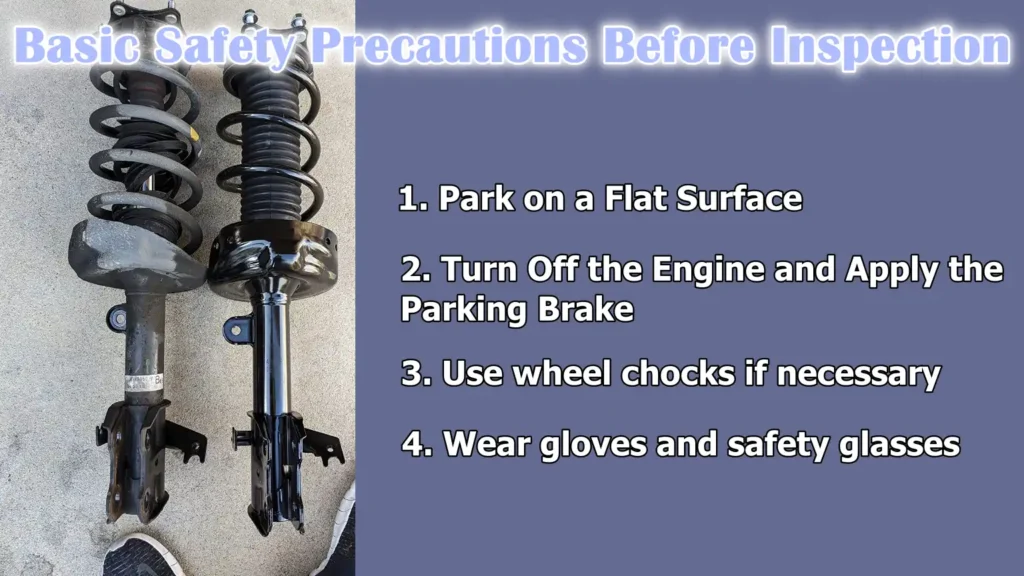

Basic Safety Precautions Before Inspection

1. Park on a Flat Surface

Before you begin inspecting your shock absorbers, it is important to park your car on a flat and level surface.

This ensures that the vehicle remains stable and does not move suddenly during the suspension check.

A flat surface also gives you a more accurate view of the car’s stance and suspension condition.

Mechanics and safety experts recommend avoiding sloping driveways or uneven ground, as this can increase the risk of the car rolling or tilting slightly when pressure is applied during tests such as the bounce test.

2. Turn Off the Engine and Apply the Parking Brake

Once the vehicle is properly parked, the next step is to turn off the engine and firmly apply the parking brake.

This prevents any accidental movement near the wheels or underneath the vehicle.

Although modern cars have advanced braking systems, it is always advisable to use the parking brake as a second level of safety during maintenance checks.

Reports from automotive safety organizations show that forgetting this simple step during a vehicle inspection at home is one of the most common causes of accidents.

3. Use wheel chocks if necessary

Wheel chocks are small wedges that are placed on the tires to prevent the car from rolling.

These are specially important when you are working on a slight slope or when there is extra stress on the car during inspection.

Professional mechanics use wheel chocks as a standard procedure when lifting a vehicle or doing suspension work.

Using them at home provides an extra layer of protection, ensuring that the car stays firmly in place even if there is any movement during the inspection.

4. Wear gloves and safety glasses

Safety equipment should never be overlooked, not even for a simple inspection.

Wearing gloves helps protect your hands from dirt, sharp edges and potential cuts from suspension parts.

Safety glasses protect your eyes from dust, rust particles or any small debris that may come out during inspection.

Automotive health and safety guidelines always recommend personal protective equipment, as even small particles coming out from under the car can cause eye injuries.

By using gloves and goggles, you not only make the inspection safer, but also more comfortable and efficient.

Visual inspection of the shock absorber

1. Check for oil or fluid leaks on the shock body

A healthy shock absorber should stay dry, but when the seals inside the unit wear out, hydraulic fluid can begin to leak from the shock body.

Even a small leak can reduce the shock’s ability to dampen vibrations and control suspension movement.

Automotive studies show that a leaking shock absorber can lose up to 50 percent of its effectiveness, which directly impacts braking distance and vehicle stability.

When inspecting, check for dark, greasy stains or moisture around the shock housing.

If fluid is present, this usually means that the internal seals are worn out and the shock absorber must be replaced, as it cannot function properly without its hydraulic fluid.

2. Check for dents, rust or physical damage

The outer surface of the shock absorber should be smooth and free of dents or heavy rust.

Any physical damage can interfere with the movement of the pistons inside the shock, which can reduce its performance or cause it to wear out completely.

Corrosion, specially deep corrosion, weakens the structure and can cause cracks over time.

Environmental conditions such as road salt, mud and moisture in the winter accelerate this process.

Research conducted by suspension manufacturers shows that corrosion damage is one of the leading causes of premature shock failure in harsh climates.

By identifying dents and corrosion early, you can prevent dangerous breakdowns and avoid costly suspension repairs.

3. Check for looseness or wear in mounting bolts, bushings and brackets

Shock absorbers are held in place by mounting bolts, bushings and brackets and all of these must be strong for the shock absorber to function properly.

Loose bolts can cause rattling sounds, while worn rubber bushings can cause excessive looseness and reduced stability.

Over time, these parts wear out from constant motion and exposure to dirt and heat.

Studies on suspension systems show that even if shock absorbers are in good condition, worn mounts and bushings can reduce performance by more than 30 percent, causing vibration, noise and poor handling.

A careful inspection includes checking that all bolts are tight, bushings are not cracked or worn and brackets are not bent or broken.

Replacing these small parts when necessary ensures that the entire shock absorber system continues to function safely and effectively.

Bounce Test (Basic Functional Test)

1. Press hard on the hood or trunk of the vehicle

The bounce test is the easiest way to check if your shock absorbers are working properly and it can be performed without any special tools.

First, press hard on the hood or trunk of your vehicle, applying enough force to compress the suspension.

This action mimics the effect of hitting a bump or pothole in the road.

Automotive experts recommend applying steady, firm pressure rather than a quick tap, as this gives the shock absorber and spring a chance to react more like normal driving conditions.

2. Release and watch the rebound

After pressing, release your hands and watch carefully how the vehicle reacts.

A healthy shock absorber will handle the rebound immediately, allowing the car to return smoothly to its normal position without delay.

Shock absorbers are designed to absorb the energy from the spring’s motion and prevent it from oscillating.

If the car lifts and stabilizes at a controlled speed, this usually indicates that the shock absorbers are still doing their job properly.

Automotive training manuals emphasize that this simple observation is one of the most effective preliminary checks that can be done at home.

3. If the vehicle bounces more than 1-2 times, the shock absorbers may be worn out

When a vehicle continues to bounce more than once or twice after being released, it usually means that the shock absorbers are worn out and no longer able to control the movement of the suspension.

Excessive bouncing indicates that the shock absorbers have lost their internal resistance, usually caused by fluid leakage or worn internal valves.

Studies on suspension performance confirm that shock absorbers lose their damping ability, which leads to increased stopping distances, reduced cornering stability and tire wear.

If this test detects frequent bouncing, it is a strong indication that the shock absorbers must be inspected more thoroughly or replaced to restore safe handling and comfort.

Road Testing for Performance

1. Driving over speed bumps or rough roads

One of the most practical ways to test shock absorbers is to drive the car over speed bumps or rough roads for a while.

Shock absorbers are designed to keep the car stable and the tires firmly attached to the ground, even if the road is rough.

With good shock absorbers, the car should immediately come to a controlled position on a rough road.

However, when shock absorbers wear out, the car may constantly bounce or feel unstable.

Automotive research shows that poor suspension response on rough roads is one of the first obvious signs of a decrease in shock absorber effectiveness.

This makes speed bumps and rough surfaces an excellent real-world test of their condition.

2. Check for excessive bouncing, poor handling or instability

During the road test, carefully observe how the car handles turns, lane changes and stops.

If the car shakes excessively, feels unstable, or continues to bounce after rough roads, the shock absorbers may be worn out.

Shock absorbers play a key role in maintaining traction by pressing the tires firmly to the road surface and without proper traction, handling performance degrades rapidly.

Studies conducted by suspension manufacturers show that worn shock absorbers can reduce vehicle stability by up to 30 percent, making emergency maneuvers more difficult and dangerous.

If you notice your car drifting, wobbling, or taking longer to stabilize after bumps, this is a clear sign that the shock absorbers need further inspection or replacement.

3. Listen for rattling sounds on rough surfaces

Another useful observation during a road test is to pay attention to unusual sounds when driving over rough roads or potholes.

Rattling, crunching or knocking sounds often indicate that the shock absorbers or their mounting components, such as bushings or bolts, are loose or damaged.

These sounds mean that the shock absorbers are unable to hold the suspension firmly in place, which can lead to more wear on other parts such as control arms, springs and tires.

Research on vehicle maintenance patterns shows that ignoring suspension sounds can turn small, inexpensive problems into costly repairs.

Paying attention to these sounds during a road test helps detect problems early and ensures that your car remains safe and comfortable to drive.

Measuring Tire Wear Patterns

1. Check the Tread for “Cupping” or Scalloped Wear

One of the most reliable signs of worn shock absorbers can be seen directly on the tires.

When the shock absorbers lose their ability to keep the tires pressed firmly to the road, the tires begin to bounce slightly when the car moves.

This constant up-and-down motion creates uneven pits in the tread, called “cupping” or “scalloped wear.

” Unlike normal, smooth tread wear, which occurs evenly across the surface, cupping appears as blotchy, wavy sections where the tread appears higher in some places and lower in others.

Tire safety research shows that cupped tires not only reduce traction, but also create additional road noise and vibration, making driving less comfortable and less safe.

Regularly checking for these abnormal wear patterns can help drivers know that shock absorbers may need to be replaced before other symptoms become apparent.

2. Uneven patterns often indicate shock absorber wear

Tires are designed to wear evenly on surfaces when the suspension system is working properly.

If you notice some tires wearing faster in certain spots, or one tire looks very different than another, it often means that the suspension system is unable to keep them balanced on the road.

Worn shocks are one of the most common causes of this problem because they are unable to control weight distribution when driving, braking and cornering.

According to studies done by tire and suspension manufacturers, poor shock performance can reduce tire life by up to 25 percent, which can lead to premature tire replacement and additional costs.

By paying attention to uneven wear patterns, drivers can detect shock failure early, extend tire life and maintain safe traction on all types of roads.

Professional Diagnostic Methods – Optional

1. Special equipment for suspension testing

Although basic methods such as bounce tests and visual inspections are useful at home, professional workshops use special equipment to measure the exact performance of shock absorbers.

One of the most accurate instruments is the shock dynamometer, which tests how well a shock absorber handles motion under simulated driving conditions.

This instrument measures resistance, damping force and response speed, providing accurate statistics that cannot be detected by a simple road test.

Another instrument used in advanced service centers is the suspension analyzer, which checks the behavior of the entire suspension system by measuring vibration levels, stability and contact of the wheels with the road.

Research conducted by automotive engineering institutes shows that electronic suspension testers can detect a reduction in shock efficiency by as much as 15-20 percent, which most drivers do not notice during everyday driving.

These diagnostic tools help confirm if shock absorbers need to be replaced and ensure that other suspension parts are still working properly.

2. When to Consult a Mechanic

Although drivers can perform many basic checks themselves, there are some situations where consulting a mechanic is the safest and most effective option.

If the car shows several warning signs, such as uneven tire wear, unusual noises, or poor handling during braking and cornering, a professional inspection is advisable.

Mechanics not only use advanced testing equipment but also have the experience to spot problems that may be missed in an at-home inspection, such as worn suspension bushings, bent control arms, or hidden fluid leaks.

Automotive safety reports emphasize that leaving suspension problems untreated can affect not only comfort but also critical functions such as braking distance and steering stability.

It’s specially important to seek expert advice before long trips, when transporting heavy loads, or if the vehicle has been driven more than 50,000 to 100,000 miles without a suspension service.

Trusting a mechanic ensures an accurate diagnosis and can prevent minor suspension problems from turning into costly or dangerous issues.

Read More:

When to Replace Shock Absorbers

1. Recommended Replacement Interval

Shock absorbers usually do not wear out suddenly; rather, they wear out slowly over time.

Most automotive experts and manufacturers recommend replacing shock absorbers between 50,000 and 100,000 miles, depending on driving conditions and the type of vehicle.

For example, cars that frequently drive on rough roads, carry heavy loads, or travel in areas with extreme weather may need to be replaced sooner than vehicles used primarily for smooth highway driving.

Research by suspension manufacturers shows that by the time 60,000 miles are reached, many shock absorbers have lost a significant portion of their damping ability, even if they are not visibly damaged.

Delaying too long in replacing worn shock absorbers can increase stopping distances, reduce tire life and affect vehicle stability, so following mileage guidelines is an important part of preventive maintenance.

2. Replace in pairs for balanced handling

When replacing shock absorbers, it’s important to replace them in pairs—either both front or both rear—rather than replacing just one.

This keeps handling and stability balanced, as mismatched shock absorbers can cause uneven control and unpredictable behavior when braking or cornering.

For example, if one front shock absorber is new and the other is worn, the vehicle may pull to one side during a sudden stop, increasing the risk of accidents.

Automotive safety studies show that balanced suspension components provide more predictable handling and reduce driver fatigue because the vehicle reacts consistently to road conditions.

Replacing shock absorbers in pairs also helps prevent uneven wear on tires and suspension parts, ultimately saving money in the long run while maintaining the highest levels of safety.

Conclusion – How to Check a Shock Absorber

Yes, you can easily forget about the vehicle’s suspension, until and unless they fails. As shock absorbers are actually silently guards the stability of your vehicle and when you replace them on time that can literally prevent lots of possible accidents and costly repairs later on.

If you see that there’s patchy ‘cupping’ on the tires then just don’t ignore them: but rather inspect the shocks and other suspension parts as well. As the tire makers note that this kind of wear pattern often starts when tire actually lose consistent road contact from weak damping. So, you have to restore the proper shock performance first and then replace or re-true tires so that you can recover grip and ride quality again.[¹]

These aren’t just comfort parts that smooth out a ride—they’re essential safety devices that directly affect braking distances, steering stability and tire life.

Studies conducted by organizations such as the National Highway Traffic Safety Administration confirm that worn shock absorbers can increase stopping distances by as much as 20 percent, which can be the difference between surviving a crash and being involved in one.

Regular inspections, such as visual checks, bounce tests, road tests and tire wear analysis, give drivers an easy way to keep track of their suspension’s health.

Professional diagnostic methods provide another level of accuracy, ensuring that even hidden problems are found before they become dangerous.

Replacing shock absorbers at the correct intervals—usually every 50,000 to 100,000 miles, depending on driving conditions—and always in pairs ensures that the vehicle remains stable and safe on the road.

By taking these steps, drivers not only ensure their safety but also extend the life of their tires, reduce repair costs and maintain fuel efficiency.

Ultimately, shock absorber care is a simple but effective way to keep a car performing at its best mile after mile.

So, now you can comment down below for more information about this guide.

Frequently Asked Questions

Q1. How often should I check my shock absorbers?

Answer: It’s a good idea to have your shock absorbers checked at least twice a year, usually during routine servicing or tire rotation. Shock absorbers wear down gradually, so you may not notice changes right away. However, after about 50,000 miles, most shock absorbers begin to lose their strength, even if they look fine from the outside. If you frequently drive on rough roads, carry heavy loads, or live in an area with bad weather, you should have them checked more often, as shock absorbers can wear out more quickly in these conditions.

Q2. What if I drive with bad shock absorbers?

Answer: Driving with bad shock absorbers is not only uncomfortable, but can also be unsafe. Worn shock absorbers make your car bounce more, reduce cornering stability and increase stopping distances. In fact, studies have shown that vehicles with weak shock absorbers can take up to 20 percent longer to stop in an emergency. They can also cause uneven tire wear, which shortens the life of your tires and increases costs. Over time, worn shock absorbers put extra stress on other suspension components, making them more expensive to repair.

Q3. How can I tell if my shock absorbers are worn?

Answer: There are several signs to tell if my shock absorbers are worn. If your car lurches forward when you brake, leans too much on turns, or bounces repeatedly on rough roads, the shock absorbers are likely weak. Another obvious sign is uneven tire wear, where the tire tread looks patchy or worn. You may also hear rattling or squeaking noises from suspension components. A simple bounce test, where you press down on the hood or trunk of the car and see how many times it bounces, can also help confirm if the shock absorbers are weak.

Q4. Do I have to replace all the shock absorbers at once?

Answer: You don’t always have to replace all four shock absorbers at once, but you should replace them in pairs, either the front two or the rear two. This keeps the car balanced and stable. If you replace just one shock absorber, handling becomes uneven, which can make braking and cornering unpredictable. Replacing them separately keeps your tires wearing evenly and the suspension working properly. Many mechanics recommend checking all four shock absorbers when replacing them to make sure the whole system stays balanced and safe.

Q5. How long do shock absorbers usually last?

Answer: The lifespan of shock absorbers depends on how and where you drive. On average, they last 50,000 to 100,000 miles. If you drive on a highway with mostly flat roads, your shock absorbers may last longer. But if you often drive on rough roads, carry heavy loads, or live in an area with a lot of potholes, your shock absorbers will wear out faster. Even if your shock absorbers don’t have any visible leaks or damage, their performance gradually decreases over time, so it’s important to follow the mileage guidelines.

Q6. Can I check my shock absorbers at home?

Answer: Yes, there are easy ways to check your shock absorbers at home. The bounce test is the easiest way. Press hard on your car’s hood or trunk, release it and see how it reacts. If it bounces more than once or twice, the shock absorbers may be worn out. You can also check for oil leaks, rust, dents or damaged mounting parts. Listening for unusual noises while driving over rough roads is also a simple home test. However, mechanics use special equipment for a more accurate check.

Q7. Why do shock absorbers affect tire wear?

Answer: Shock absorbers keep your tires firmly pressed to the road. When shock absorbers are weak, tires bounce and lose stable contact, causing an uneven wear pattern called cupping or scalloping. This not only shortens the life of your tires but also reduces traction, especially on wet or slippery roads. Studies show that worn shock absorbers can reduce tire life by up to 25 percent, making regular shock absorber inspections important for both safety and saving money.

Q8. If I suspect bad shock absorbers, should I see a mechanic?

Answer: Yes, if you notice any warning signs like bouncing, poor handling, strange noises or uneven tire wear, it’s best to visit a mechanic. Although simple checks can be done at home, professionals use equipment like suspension analyzers or shock dynamometers that measure the exact performance of shocks. A mechanic can also check related parts like bushings, control arms and mounts, which often wear out along with the shock itself. Getting a professional inspection ensures an accurate diagnosis and can prevent further damage.

References:

[1] Tire Cupping: Causes, Problems and Prevention

https://www.bridgestonetire.com/learn/maintenance/tire-cupping/

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.