Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Basically, the car bushings are flexible joints that keeps your suspension moving safely, plus it also responsible for maintaining car’s comfort and stability which is very much dependent on them as well.

Also, these small rubber or polyurethane components actually acts as cushions between the suspension parts such as: control arms, sway bars and shock mounts as well.

And their main job is to absorb the road shocks, reduce the vibrations and it keeps the metallic components from rubbing against each other.

So, it is also true that over the period of time and usage, due to the constant movement, heat and exposure to dirt or road salts, the bushings naturally wear out or crack up a little.

And if the bushings are worn out then it can cause clunking noises, poor steering response, uneven tire wear and even it is not safe as it results to the unsafe handling as well.

You should know that according to the automotive maintenance data, most of the bushings last between 80,000 to 100,000 miles, even this lifespan can be shorten in rough driving conditions.

Which is why you should understand about early signs of wear before they affect alignment of your car, tire life or ride comfort as well, so this is the guide that shows you How to Check Suspension Bushings.

Tools

| Tool / Material | Purpose / Why It’s Needed | Helpful Tips for Use |

|---|---|---|

| Jack and Jack Stands / Hydraulic Lift | It is used to raise your car off the ground and hold it securely so you can easily access the suspension parts. | Always lift from the correct jack point specified in your car’s manual. Never rely solely on the jack—use stands for safety. |

| Flashlight or Inspection Light | This allows you to clearly see the bushes and small cracks or wear under the vehicle. | A bright LED light or headlamp makes it easier to work without hands. Check from different angles for better visibility. |

| Pry Bar or Large Screwdriver | Used to gently shake suspension parts and test for looseness in bushings. | Apply slow, steady pressure—don’t press too hard. Pay attention to the movement between the metal parts and the rubber bushing. |

| Safety Gloves and Goggles | Protect your hands and eyes from dirt, rust, or debris when inspecting under the car. | Choose comfortable gloves for better grip and comfort. Always wear goggles when working under the vehicle. |

| Torque Wrench (Optional) | It is used to tighten bolts correctly if you loosen or reinstall a part. | Check the torque value in your car’s service manual to avoid over-tightening. |

| Service Manual (Vehicle Guide) | Provides accurate diagrams, torque details and bushing locations for your car model. | Keep it with you while you work – it saves time and prevents mistakes. |

Let’s Take Safety Precautions

Checking suspension bushings requires you to work underneath your vehicle, so safety should always be the top priority.

Taking the correct safety steps not only prevents injuries but also ensures your inspection goes smoothly and correctly.

Below are the most important safety precautions, explained in simple terms to make each step clear and easy to understand.

1. Park the Vehicle on a Level, Stable Surface and Engage the Parking Brake

Before doing anything, ensure your car is parked on a level and solid surface, such as a driveway or garage floor.

This helps prevent the vehicle from rolling or shifting while you’re working underneath it.

Fully engage the parking brake to securely hold the car in place.

Avoid working on uneven ground, soft soil, or sloped areas, as the vehicle can easily shift or slide when lifted.

A solid and level surface keeps your car stable and safe during the inspection.

2. Use Wheel Chocks to Prevent Rolling

Wheel chocks are small wedges that you place behind or in front of the tires to prevent any unwanted movement.

Even with the parking brake engaged, the car can still roll slightly when lifted.

Placing chocks on the wheels that remain on the ground provides an extra layer of safety.

You can use rubber or metal wheel chocks and if you don’t have them, sturdy wooden blocks can serve as a temporary alternative.

This simple step can make a big difference in preventing accidents.

3. Safely Lift the Vehicle Using the Manufacturer’s Specified Jack Points

Every car has specific jack points designed to safely handle the weight.

You can find these points in your vehicle’s owner’s manual.

Always place the jack under these designated locations – never under thin metal parts, body panels, or suspension arms.

Lifting your vehicle from the wrong place can damage it and make it unstable.

Lift the car slowly and steadily and constantly check that it remains balanced as you lift it.

4. Always support the vehicle with jack stands before performing any work

Once the car is lifted, never rely solely on the jack to hold it up.

A hydraulic jack is for lifting, not for prolonged support.

After lifting the vehicle, securely place the jack stands under the correct support points and gently lower the car onto them.

Before proceeding, gently shake the vehicle to ensure it is stable.

Jack stands are strong, stable and specifically designed to safely support the vehicle while you work.

This is one of the most important steps for your safety.

How to Check Suspension Bushings – Full Method

Carefully checking your suspension bushings helps you understand the true condition of your vehicle’s suspension system.

Bushings are designed to absorb road shocks and reduce vibrations, but over time they can dry out, crack, or wear down.

A detailed inspection ensures you identify problems early, before they affect steering, ride comfort, or safety.

The first and most crucial part of the inspection process is a visual check, which helps you identify any visible signs of damage or deterioration.

How to Inspect it Visually

The first and most crucial step in checking your car’s suspension bushings is a visual inspection.

This helps you assess the extent of wear or damage and determine if replacement is necessary.

As bushings connect and cushion various suspension components, early detection of their condition can prevent further problems such as noise, vibration, or poor handling.

1. Locating the Suspension Bushings

Before beginning the inspection, it’s essential to know where the bushings are located.

In most vehicles, suspension bushings are found in the control arms, sway bars, trailing arms and shock or strut mounts.

These bushings act as flexible joints that allow the parts to move freely while absorbing shocks and vibrations from the road.

Understanding their location helps you thoroughly inspect each one and ensures you don’t miss any during the inspection.

When locating them, use your vehicle’s service manual or a suspension diagram for guidance.

This helps confirm the correct locations for your specific car model, as bushing locations may vary slightly between front and rear suspension systems.

2. Lighting and Visibility During Inspection

Proper lighting is crucial for a clear and safe inspection.

Use a bright flashlight or a small inspection light to illuminate the dark areas under the car.

As bushings are often hidden behind suspension arms or near the frame, direct lighting makes it easier to see subtle changes in the surface.

A portable LED light or headlamp can free up both hands for better precision.

Clear visibility helps you notice signs of damage that might be missed in poor lighting.

3. Inspecting the Condition of the Bushings

Once you have a clear view, carefully examine the surface of each bushing.

A healthy rubber or polyurethane bushing should appear smooth, flexible and slightly firm to the touch.

If you see cracks, tears, or missing pieces, it’s an indication of material degradation.

Even minor surface cracks suggest that the bushing is beginning to age and lose its flexibility.

Deep cracks or missing material usually mean the bushing can no longer properly cushion and should be replaced soon.

Also, look for any looseness, distortion, or uneven shape.

A bushing that appears out of place or shifted from its metal sleeve may indicate wear or misalignment due to repeated stress or improper installation.

4. Identifying Signs of Dry Rot and Brittleness

Over time, exposure to heat, sunlight, moisture and road salt can cause rubber bushings to dry out and harden.

This process is called dry rot.

When the rubber loses its natural oils, it becomes stiff and brittle and often develops small surface cracks.

You can detect dry rot by gently pressing on the bushing’s surface.

If it feels hard or makes a cracking sound, it has likely lost its flexibility.

Dry or brittle bushings can no longer properly absorb road vibrations, resulting in a rough or noisy ride.

5. Checking for Oil or Fluid Contamination

Another common cause of bushing failure is contamination from engine oil, power steering fluid, or transmission fluid.

Rubber and petroleum-based fluids don’t mix well – prolonged contact can cause the rubber to swell, soften, or dissolve.

During the inspection, look for any wet or shiny surfaces near the bushings.

If you see signs of oil leakage around the suspension area, it’s best to first clean the area and fix the source of the leak.

Contaminated bushings should be replaced immediately, as the rubber can weaken and fail under stress.

How to do Physical Movement Test

The physical movement test is the second crucial part of inspecting your suspension bushings.

While a visual inspection reveals visible wear and tear, this test helps you confirm how the bushing behaves under pressure and movement.

Suspension bushings are designed to absorb vibrations and provide controlled flexibility between parts.

When they wear out, they lose their elasticity, causing the connected components to move excessively or make noise.

Performing a movement test helps you feel and hear signs of looseness that aren’t always visible during a visual check.

1. Using a Pry Bar or Large Screwdriver

To begin, use a sturdy pry bar or a large flat-head screwdriver to gently apply pressure to the suspension arm or the part connected to the bushing.

The goal here isn’t to forcefully move the part, but rather to observe how much movement the bushing allows.

Carefully insert the tool between the suspension arm and a sturdy mounting point and then gently push or pull.

Observe how the rubber or polyurethane bushing reacts to this pressure.

A good bushing will flex slightly but return immediately to its original position when the pressure is released.

This slight movement indicates that the material is still elastic and performing as it should.

2. Looking for Excessive Movement or Separation

As you move the suspension component, observe the area where the bushing meets the metal parts.

Excessive movement, noticeable looseness, or visible gaps between the metal and the bushing are strong indicators of wear.

In a properly functioning bushing, the metal sleeve should remain firmly in place with only slight flexing of the rubber.

If you see the metal parts touching or separating from the bushing, it means the inner material has deteriorated or separated from its mount.

This separation can cause a loose and unstable suspension, leading to steering problems, uneven tire wear and poor alignment.

When inspecting, check both sides of the suspension arm if possible, as sometimes the damage is only visible on one side of the bushing while the other side appears fine.

Testing multiple points of the suspension will give a more accurate assessment of its overall condition.

3. Listening for Knocking or Unusual Noises

Noise is another important indicator of bushing health.

While applying pressure with a pry bar, listen carefully for any knocking, rattling, or creaking sounds.

These noises are typically caused by metal parts coming into direct contact due to a worn rubber layer.

A dull knocking sound is one of the most common symptoms of a completely worn bushing.

You may also hear a creaking sound if the bushing has dried out and lost its flexibility.

These noises are often similar to those heard when driving on rough roads or turning corners, confirming that the bushings are no longer providing proper cushioning.

4. Understanding the Test Results

If the bushings only exhibit slight flexing and return to their normal shape, they are likely still in good condition.

However, if you feel looseness, separation, or hear knocking noises, replacement is necessary.

Worn bushings can lead to handling issues, premature tire wear and increased stress on other suspension components.

A physical movement test clearly shows how well your suspension system performs under load and helps prevent more serious mechanical problems in the future.

How to Have the Road Test Confirmation

The road test confirmation is the final and most practical step in checking the condition of your suspension bushings.

While visual inspection and physical testing reveal how the bushings look and react when the car is stationary, the road test shows how they perform under actual driving conditions.

Suspension bushings are designed to cushion every movement of the car – from steering and cornering to braking and accelerating.

When they wear out, these everyday movements can feel rough, noisy, or unstable.

Driving the car for a short period and listening carefully will help you confirm the symptoms that indicate worn or damaged bushings.

1. Listening for Noises Over Bumps

As you begin the road test, pay attention to the sounds your vehicle makes when it goes over bumps, potholes, or uneven surfaces.

Healthy bushings quietly absorb shocks, keeping the suspension stable and smooth.

However, when bushings become loose or cracked, they allow metal parts to collide, resulting in knocking, rattling, or creaking noises.

A light thud when going over a bump usually indicates a loose control arm bushing, while a continuous creaking often means the bushing has become dry or stiff.

Listen for noises from both the front and rear of the vehicle, as multiple bushings can wear at different rates.

This sound check will help you pinpoint which part of the suspension needs attention.

2. Feeling for Instability and Vibrations in the Steering

Next, pay attention to how your steering feels, specially at higher speeds or when taking turns.

Worn bushings can no longer hold suspension components firmly in place, allowing for movement that translates directly to the steering wheel.

If the steering feels loose, shaky, or unresponsive, it could be a sign that one or more bushings have lost their integrity.

You might also feel vibrations in the steering wheel or through the floorboard, which occurs when the suspension is no longer properly absorbing road vibrations.

This vibration often increases with speed and is a key indicator that your bushings have hardened or separated from their mounts.

A stable steering feel is a sign of good suspension health, so any unusual movement should be taken seriously.

3. Observing Unusual Handling or Vehicle Pulling to One Side

During your drive, pay attention to whether your car handles evenly when turning or driving straight.

A vehicle that pulls to one side, feels unbalanced, or leans excessively when turning may have bushings that are more worn on one side than the other.

Because bushings play a role in maintaining alignment and geometry, uneven wear can cause suspension arms to shift out of place.

This not only affects handling but also leads to accelerated tire wear and puts added stress on other parts like ball joints and struts.

Try driving on a smooth, straight road and gently release the steering wheel to see if the car drifts to one side.

If it clearly pulls to one side, it could indicate misalignment due to worn bushings or damaged mounts.

4. Understanding the Results of the Road Test

After completing the drive, take note of any noises, vibrations and handling behaviors you experienced.

If you hear knocking noises, feel looseness in the steering, or experience uneven handling, it’s likely that one or more bushings are worn or damaged.

A vehicle with good bushings should run quietly, the steering should turn smoothly and it should maintain balance even on rough roads.

If these symptoms persist, it’s best to have a professional mechanic inspect the suspension to determine which bushings need replacing.

Read More:

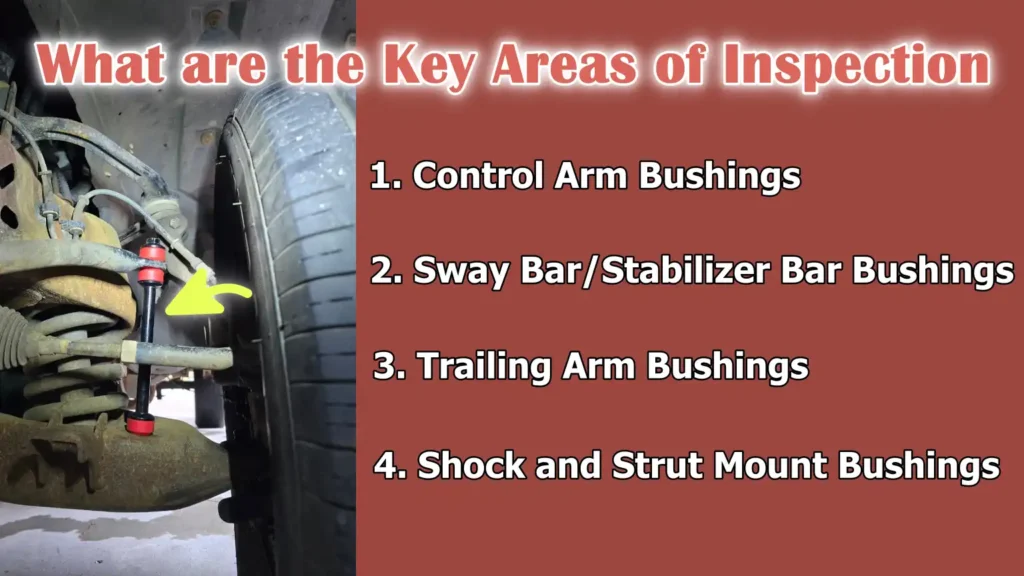

What are the Key Areas of Inspection

When inspecting suspension bushings, it’s crucial to understand that not all bushings wear out at the same time or in the same way.

Some parts of the suspension system experience more movement, stress and heat than others, making certain bushings more prone to premature failure.

Knowing which areas to focus on helps you inspect efficiently and identify problems before they escalate into major suspension issues.

Key areas of inspection include control arm bushings, sway bar bushings, trailing arm bushings and shock or strut mount bushings.

Each of these plays a specific role in your vehicle’s handling, ride and response to road conditions.

1. Control Arm Bushings

Control arm bushings are often among the first to fail because they handle the most movement and load in the suspension system.

These bushings connect the control arms to the vehicle’s frame and help maintain proper wheel alignment.

When in good condition, they keep the wheels stable and in the correct position as the suspension moves up and down.

Over time, constant stress and exposure to road debris can cause them to crack, tear, or become loose.

Worn control arm bushings often result in steering instability, vibrations during acceleration and uneven tire wear.

You may also hear a knocking sound when braking or turning as the arm is no longer held tightly in place.

Regularly inspecting these bushings can prevent steering and alignment problems that affect driving safety and tire life.

2. Sway Bar/Stabilizer Bar Bushings

Sway bar bushings, also known as stabilizer bar bushings, play a crucial role in minimizing body roll when your car turns or corners.

These bushings securely hold the sway bar to the chassis, allowing it to twist and balance the car’s weight from side to side.

When they wear out, the sway bar can move loosely within its mounts, causing rattling or knocking noises, specially when driving on rough roads or uneven surfaces.

You might also notice the car leaning more than usual on sharp turns or feeling less stable when changing lanes.

As these bushings are typically made of rubber or polyurethane, they can dry out or shrink over time.

Keeping them in good condition ensures better cornering stability and overall driving comfort.

3. Trailing Arm Bushings

Trailing arm bushings are found in the rear of many vehicles and help control the fore and aft movement of the rear wheels.

Their main purpose is to keep the rear suspension aligned and stable, while also maintaining a smooth ride, even on bumpy roads.

When these bushings wear out, the vehicle may wander or sway slightly when driving in a straight line.

You might feel a looseness or sloppiness in the rear of the car, specially when accelerating or braking.

Worn trailing arm bushings can also lead to uneven wear on the rear tires and a decrease in ride comfort, as they can no longer properly absorb road vibrations.

Inspecting these bushings is specially important for vehicles that frequently travel on rough roads or carry heavy loads, as they are constantly subjected to vertical and horizontal forces.

4. Shock and Strut Mount Bushings

Shock and strut mount bushings cushion the connection between the suspension struts or shocks and the vehicle’s body.

They are crucial for reducing road noise and vibrations before they reach the cabin.

When these bushings wear out, the most common symptoms include a knocking sound when driving over bumps and a noticeable decrease in ride comfort.

You may also experience increased vibrations inside the vehicle because the shocks are no longer properly isolated.

In severe cases, worn strut mount bushings can lead to uneven suspension movement, affecting both handling and braking performance.

Replacing worn mount bushings restores smoothness and allows the suspension system to absorb shocks more effectively.

When to Replace Suspension Bushings

Knowing when to replace your suspension bushings is just as important as knowing how to inspect them.

Bushings are designed to last for many miles, but like any wear-and-tear component, they eventually lose their flexibility and effectiveness.

Their lifespan depends on driving conditions, weather, vehicle load and maintenance habits.

Typically, suspension bushings can last 80,000 to 100,000 miles under normal driving conditions, but they can wear out much faster in vehicles driven on rough or unpaved roads.

Replacing worn bushings at the right time can prevent costly suspension damage, improve steering stability and restore ride comfort.

Below are the key signs and conditions that clearly indicate it’s time to replace your suspension bushings.

1. Cracks Extending More Than Halfway Through the Rubber

Rubber bushings naturally develop small surface cracks over time due to constant flexing and exposure to heat, moisture and road debris.

However, when these cracks extend more than halfway through the rubber or across the entire surface, the bushing can no longer properly absorb vibrations.

Deep cracks mean the material has become weak and brittle, allowing suspension components to move more freely than intended.

This can lead to noise, vibrations and uneven wear on surrounding parts.

If you see large chunks or missing pieces of rubber during inspection, replacement is necessary as the bushing’s ability to cushion and stabilize the suspension has been compromised.

2. Visible Metal-to-Metal Contact

One of the most serious warning signs is visible metal-to-metal contact between the suspension arm and its mounting point.

Bushings act as a soft barrier separating these metal components.

When the rubber layer wears down or completely breaks, the metal parts come into direct contact with each other.

This not only causes knocking or grinding noises but also damages the suspension brackets and control arms.

Prolonged metal-on-metal contact can wear down the mounting points and affect the vehicle’s overall alignment.

If you see shiny metal marks or scratches where the bushing used to provide cushioning, it means the rubber has completely failed and should be replaced immediately to prevent structural damage.

3. Excessive Play or Movement During Inspection

During a physical movement test, if the suspension arms or other components move more than a few millimeters or feel loose when pressure is applied, the bushings are worn out.

Excessive play occurs when the rubber can no longer properly grip the metal sleeve.

This looseness allows the suspension to be affected by bumps and steering inputs, making the car feel unstable or imprecise.

Even if the bushing looks fine from the outside, excessive movement means the inner core has deteriorated or separated from the outer shell.

Replacing the bushings restores proper alignment and reduces unnecessary flex in the suspension system, directly improving handling and comfort.

4. Unstable or Noisy Ride Despite Other Parts Being in Good Condition

If your vehicle still feels unstable, bouncy, or noisy even after replacing other suspension parts like shocks, struts, or tie rods, worn bushings could be the hidden cause.

Worn bushings can make the entire suspension feel loose and disconnected, leading to vibrations, rattling noises, or excessive body roll when cornering.

As bushings support and connect almost every suspension component, even a single worn bushing can affect the performance of the entire system.

When the rest of the suspension appears to be in good condition but the ride quality is still poor, it’s a strong indication that the bushings have lost their effectiveness and need to be replaced.

How to Maintenance Suspension Bushings

Proper maintenance of suspension bushings is the most effective way to extend their lifespan and maintain your vehicle’s comfort, stability and performance.

Although bushings are small and often overlooked, they play a crucial role in keeping the suspension system quiet and responsive.

Regular care can prevent premature wear, cracking and deterioration caused by harsh conditions, dirt, or improper maintenance.

Adopting a few simple habits during vehicle servicing can make a significant difference in how long your bushings last and how well your suspension performs over time.

Plus, the tests also shows that the most of the bushings actually fail from the repeated but small loads rather than one big hit, that is why drivers sometimes notices gradual noise or looseness after many miles, as the material slowly accumulates damage until the movement becomes very big.[¹]

1. Keeping Bushings Clean and Inspecting Them Regularly

Dirt, road grime and salt can accumulate around suspension components and gradually degrade the bushings.

Periodically cleaning them during oil changes or tire rotations helps maintain flexibility and protects the surface from damage.

When cleaning, use mild soap and water instead of harsh chemicals, as strong cleaners can dry out the rubber and reduce its elasticity.

During inspections, look for cracks, swelling, or uneven wear, which may indicate underlying problems such as misalignment or a faulty suspension component.

It’s best to inspect the bushings at least twice a year or whenever you hear any new noises from your suspension.

Regular inspections ensure you can identify wear early and replace the bushings before they damage other parts.

2. Avoiding Contamination from Oils, Greases and Solvents

One of the primary causes of premature bushing failure is exposure to oils, greases, or automotive fluids.

Petroleum-based substances can soften or dissolve the rubber material, causing it to swell, crack, or completely lose its structural integrity.

When changing oil, performing brake service, or doing any undercarriage work, be careful not to drip fluids onto the suspension bushings.

If there is a leak near the suspension area, such as from a valve cover gasket or power steering system, it should be repaired immediately to prevent fluids from soaking into the rubber.

Polyurethane bushings are more resistant to chemicals, but they can also degrade if constantly exposed to oil or solvents.

Keeping the area clean and dry helps maintain the bushings’ ability to dampen vibrations and reduce noise.

3. Using OEM-Quality or Performance-Grade Replacements

When it’s time to replace the bushings, the quality of the replacement parts makes a significant difference in performance and durability.

Original Equipment Manufacturer (OEM) bushings are designed to match the exact specifications and flexibility of the factory-installed components, ensuring proper ride comfort and handling.

Cheaper aftermarket bushings may fit, but they often use lower-grade rubber that degrades quickly or alters the suspension geometry.

For those who prefer sporty handling or drive performance vehicles, performance-grade polyurethane bushings offer greater durability and longevity, although they may result in slightly more road noise.

Choosing the right type for your driving style and conditions ensures your suspension continues to perform as intended without compromising comfort or safety.

Conclusion – How to Check Suspension Bushings

It is true that the condition of your vehicle’s suspension bushings actually becomes deciding factor that your car feel old or solid, that level of impact it makes as suspension bushings prevents annyoing noise and poor steering control as well.

Bushings may seem small and simple, but they perform a crucial function: they isolate vibrations, absorb shocks and keep suspension components properly aligned.

When they start to wear out, you might experience loose steering, clunking noises over bumps, or uneven tire wear.

Over time, neglected bushings can put excessive stress on control arms, sway bars and shocks, leading to costly repairs that could have easily been avoided with timely inspection.

Performing visual checks, physical movement tests and road confirmations allows you to identify problems long before they become major issues.

Whether you’re a professional mechanic or a car owner who likes to perform basic maintenance, knowing how to inspect bushings helps you better understand your vehicle’s handling and identify problems early.

Replacing worn bushings promptly restores smooth handling, reduces noise and maintains proper alignment.

Now, you can ask questions and unsolved queries in the comment section of this guide.

Frequently Asked Questions

Q1. What are suspension bushings and what do they do?

Answer: Suspension bushings are small rubber or polyurethane components that are installed between the metal parts of your vehicle’s suspension system, such as control arms, sway bars and shock mounts. Their job is to absorb vibrations, reduce noise and allow for flexible movement between parts. Without bushings, your ride would be rough and noisy because the metal components would be in direct contact with each other. They also help maintain proper wheel alignment, resulting in smoother handling and less tire wear.

Q2. How do I know if my suspension bushings are bad?

Answer: You can usually tell if your suspension bushings are going bad when you start to feel vibrations in the steering wheel, hear knocking or creaking noises when driving over bumps, or if your car feels unstable when turning or braking. Sometimes, you might also notice uneven tire wear or poor alignment. During an inspection, visible cracks, gaps, or missing pieces in the rubber are clear signs that the bushings are failing. If your ride feels loose or your steering doesn’t feel precise, that’s a strong indication that your bushings need attention.

Q3. Can I check my suspension bushings at home?

Answer: Yes, you can check your suspension bushings at home if you have some basic tools and carefully follow safety procedures. You will need a jack, jack stands, a flashlight and a pry bar. Once the car is safely lifted and supported, you can visually inspect the bushings for cracks, wear, or oil stains. You can also gently wiggle the suspension arms or components with a pry bar to check for excessive play. However, if you feel uncertain or uncomfortable working under the car, it’s always best to have a professional mechanic inspect it.

Q4. How long do suspension bushings typically last?

Answer: The lifespan of suspension bushings can vary depending on driving conditions, climate and the quality of the materials used. On average, rubber bushings can last anywhere from 50,000 to 100,000 miles. However, poor road conditions, extreme temperatures, or exposure to oil and road salt can cause them to deteriorate much faster. Polyurethane bushings typically last longer than rubber bushings but may result in slightly more road vibration. Regular inspections and maintenance can help you detect wear and tear early and extend their lifespan.

Q5. What happens if I continue driving with worn suspension bushings?

Answer: Driving with worn suspension bushings can lead to several problems over time. It can cause loose steering, uneven tire wear and poor handling, making your vehicle difficult to control, specially at high speeds. It can also cause other suspension parts, such as control arms or sway bars, to wear out prematurely due to increased movement and vibration. Ultimately, this can lead to costly repairs and unsafe driving conditions. Replacing worn bushings promptly can prevent these problems and keep your car running smoothly.

References:

[1] Fatigue life prediction of rubber suspension bushings based on virtual road load spectrum pulses

https://www.sciencedirect.com/science/article/pii/S2590123024009484

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.