Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Basically head gasket is just like a car’s invisible shield, as it keeps the engine oil and coolant from mixing while it seals the cylinders and in that way it produces the smooth power and even a small leak in the head gasket can actually make your engine overheat, that reduces the fuel efficiency and it causes the long-term damage as well.

Plus, the head gasket is one of the most critical components in car’s engine which is sitting between the engine block and cylinder head.

So, whenever the head gasket fails, then it often referred to as a “blown head gasket” and it can even lead to the serious engine problems such as: overheating, loss of power and even complete engine failure as well if it didn’t addressed quickly.

Yes, there’s are several signs of a blown head gasket which may include white smoke from the exhaust, milky oil, unexplained coolant loss or engine misfires as well.

Now, let’s understand about these warning signals early with this guide on How Can You Tell if a Head Gasket Is Blown.

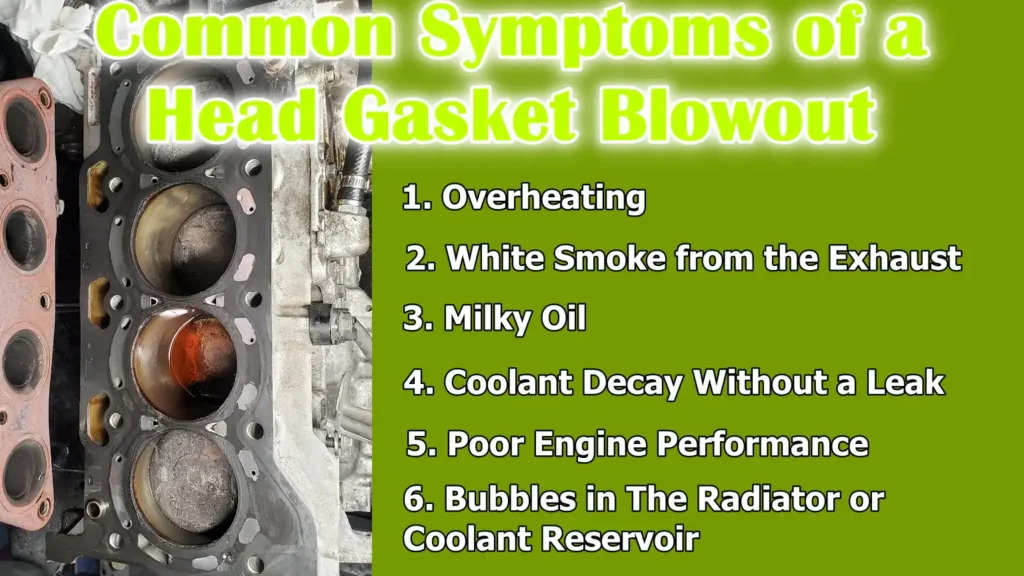

Common Symptoms of a Head Gasket Blowout

1. Overheating

One of the earliest symptoms of a blown head gasket is the engine overheating frequently.

The head gasket is responsible for maintaining the proper flow of coolant between the engine block and the cylinder head.

When it wears out, coolant can leak in or out, causing it to not circulate properly.

This reduces the engine’s ability to stay cool, causing temperatures to rise rapidly even under normal driving conditions.

Continuing to run an overheated engine can cause serious damage, including warping of the cylinder head or cracking of the engine block.

2. White Smoke from the Exhaust

Another telltale sign of a blown head gasket is white smoke coming out of the exhaust pipe.

This happens when coolant leaks into the engine’s combustion chamber.

As the coolant burns with the fuel, it creates thick white smoke that is easily recognizable, specially when the engine is cold or has just been started.

Ignoring this symptom can cause major damage to the engine, as coolant loss continues and internal parts begin to overheat or wear out prematurely.

3. Milky Oil

If the engine oil appears milky, foamy or creamy, it’s a sure sign that coolant is getting into the oil due to a blown head gasket.

The head gasket’s job is to keep oil and coolant separate, so this contamination affects the oil’s ability to properly lubricate the engine.

Driving with milky oil can increase wear on critical engine parts like pistons, bearings and the crankshaft, ultimately leading to costly repairs or engine damage.

4. Coolant Decay Without a Leak

Sometimes the coolant level drops even if there’s no visible leak outside the engine.

This happens when coolant leaks from the inside, often into the cylinders or oil passageways, due to a damaged head gasket.

Drivers may need to refill coolant frequently, but there is no puddle underneath the car.

If left unattended, this internal decay can lead to engine overheating, poor engine performance and serious damage to engine parts.

5. Poor Engine Performance

A blown head gasket can also affect the engine’s overall performance.

The engine may experience misfiring, sluggish running, a loss of power or slow acceleration.

This happens because the engine cylinders are not sealing properly, leading to incomplete combustion and uneven pressure.

Poor performance can be gradual and subtle at first, making it easy to overlook the problem until it becomes severe.

6. Bubbles in The Radiator or Coolant Reservoir

Exhaust gases escaping into the cooling system are another symptom of a blown head gasket.

These gases create bubbles in the radiator or coolant reservoir, which can sometimes be visible when the engine is running.

The presence of bubbles indicates that combustion gases are entering the cooling system, reducing its efficiency and potentially causing overheating.

Early detection is important to prevent further damage to the engine.

How to Perform Diagnostic Tests

1. Check the Oil Cap

An easy way to check for a blown head gasket is to inspect the oil cap.

When the head gasket is worn, coolant can mix with the engine oil, causing it to have a milky, foamy, or creamy color.

Removing the oil cap and checking for this residue can quickly identify a worn gasket.

This test is easy and doesn’t require any special tools, so it’s a good first step for car owners who want to identify potential problems before serious damage occurs.

2. Inspect the Exhaust Smoke

Inspecting the exhaust smoke is another practical diagnostic method.

A blown head gasket can cause coolant or oil to enter the combustion chamber, producing smoke of different colors when burned.

White smoke usually indicates that coolant is leaking into the cylinder, blue smoke indicates that oil is burning and black smoke indicates excessive fuel.

Paying attention to changes in the color and density of exhaust smoke can help detect problems early and prompt further investigation.

3. Cooling System Pressure Test

The cooling system pressure test helps identify leaks that are not externally visible.

By applying pressure to the radiator or coolant system with a hand pump, car owners can see if the pressure in the system is dropping, which is a sign of a possible internal leak caused by a blown head gasket.

This test is effective in detecting leaks between the engine block and the cylinder head, which are common areas affected by a bad gasket.

It provides a more accurate understanding of the condition of the engine than just a visual inspection.

4. Compression Test

The compression test measures the pressure inside each cylinder to ensure they are sealing correctly.

When the head gasket is blown, the leak can cause some cylinders to lose pressure, resulting in uneven compression readings.

This test requires a compression gauge, but it provides valuable information about the engine’s health, helping to determine which cylinder or cylinders may be affected.

Early detection of low or inconsistent compression can prevent serious engine damage.

5. Chemical Testing (Block Testing)

The chemical test, also called the block test, is designed to detect exhaust gases in the coolant.

Special test fluids change color when exposed to combustion gases, indicating that the head gasket is leaking.

This test is highly reliable and can confirm a blown gasket even when other symptoms are subtle or invisible.

It is an important diagnostic tool for those who are serious about accurately identifying the problem without disassembling the engine.

How to Perform Professional Diagnosis

1. Why Professional Confirmation Is Often Necessary

Although self-testing can help detect early symptoms of a blown head gasket, confirming the problem often requires the expertise of a professional mechanic.

Head gasket failure can be a sign of other engine problems such as cracks in the engine block, warped cylinder heads, or even a simple coolant leak.

Professional diagnosis ensures that the correct problem is identified before costly repairs begin.

Mechanics can also assess the severity of the damage and suggest whether the gasket can be repaired or the engine needs more extensive repairs.

2. Tools and Tests Used by Professionals

Professional mechanics use special tools and tests to accurately diagnose a blown head gasket.

A compression test checks for proper pressure in each cylinder and identifies leaks.

A leak-free test is a more accurate method that determines where compression is being lost.

Mechanics can also perform a visual inspection for cracks or damage in the cylinder head and gasket area using a borescope, a small camera inserted into the engine.

In addition, chemical tests, also known as block tests, confirm internal leaks by detecting exhaust gases in the coolant.

These professional tools and techniques provide reliable results that go far beyond DIY methods, helping car owners make informed repair decisions.

What are The Consequences of Ignoring a Broken Head Gasket

1. Engine Overheating

The most immediate and serious consequence of ignoring a broken head gasket is engine overheating.

When the gasket wears out, coolant can leak into the cylinders or out of the engine, reducing its ability to effectively regulate temperatures.

Continued overheating can damage engine components such as pistons, valves and the cylinder block.

If the engine temperature rises too high, it can lead to a complete breakdown, causing the vehicle to stop working and damaging other systems such as the radiator and hoses.

2. Bent or Cracked Cylinder Head

A broken head gasket can distort or even crack the cylinder head.

The cylinder head is right above the gasket and faces extreme heat and pressure.

If the gasket wears out, the uneven pressure and overheating can cause the cylinder head to distort or even crack.

A bent or cracked cylinder head affects engine sealing, compression and overall performance and is far more costly and time-consuming to fix than replacing a gasket.

3. Expensive repairs or complete engine replacement

Ignoring a blown head gasket can quickly lead to increased repair costs.

Minor gasket leaks may initially only require a gasket replacement, but prolonged neglect can often lead to serious engine damage, including damage to pistons, valves and the cylinder head.

In severe cases, engine repair may be completely impossible, requiring the entire engine to be replaced.

This can cost thousands of dollars, so timely detection and repair are essential for both safety and economical reasons.

Preventive Maintenance Tips

1. Regular Coolant Flushes

Performing regular coolant flushes is one of the most effective ways to prevent head gasket failure.

Over time, coolant can become contaminated with rust, dirt or debris, reducing its ability to absorb heat and protect the engine.

Flushing the cooling system removes these contaminants and ensures that fresh coolant continues to circulate efficiently, helping to maintain engine temperature and reduce stress on the head gasket.

Following the manufacturer’s recommended intervals for coolant replacement is essential to the long-term health of the engine.

2. Monitoring Engine Temperatures

Keeping a close eye on engine temperatures is a simple but important preventive measure.

Overheating is a major cause of head gasket failure and early detection of rising temperatures can prevent serious damage.

Car owners should regularly check the temperature gauge while driving and pay attention to warning lights.

If the engine begins to heat up more than normal, it is important to stop immediately and investigate the cause rather than continue driving, as this can cause further damage to the gasket and other engine parts.

3. Ensuring Proper Torque on Head Bolts

The head bolts play a critical role in keeping the cylinder head and head gasket tightly sealed.

If the bolts are not torqued correctly during maintenance or repair, this can lead to uneven pressure, leaks and ultimately gasket failure.

Using a torque wrench to tighten the bolts according to the manufacturer’s specifications ensures a proper seal, prevents the cylinder head from warping and extends the life of the head gasket.

4. Using the Correct Coolant and Oil Mixture

Using the correct type of coolant and engine oil is essential to protecting the head gasket and the overall health of the engine.

Different engines require specific coolant formulations and oil grades to maintain proper lubrication and cooling.

Mixing incompatible fluids or using low-quality products can reduce gasket durability, increase engine wear and increase the risk of overheating.

Following the car manufacturer’s recommendations for both coolant and oil ensures optimal performance and longevity of engine parts.

Read More:

Conclusion – How Can You Tell if a Head Gasket Is Blown

Whenever you find if there’s any change in engine such as: there’s milky oil or unusual kind of smoke is seen, then it literally means you are ignoring warning lights on your car’s lifespan.

Not only this, engineering studies also shows that most of the head-gasket damage happens because of there’s a problem with their cooling system, which is why you should schedule the coolant flushes and fix if there’s any overheating problem is happening.[¹]

From overheating and white smoke to milky oil and poor engine performance, these symptoms are clear signs that immediate attention is needed.

Early detection through simple DIY tests and professional diagnosis when needed can prevent minor issues from becoming major problems.

Maintaining your vehicle with regular coolant flushes, proper torque on head bolts and the right oil and coolant mixture not only protects the head gasket, but also ensures the engine runs efficiently for a long time.

By being vigilant and proactive, you can save both money and stress while keeping your car reliable and safe on the road.

Now, you can comment down below for more information about this guide.

Frequently Asked Questions

Q1. How can I tell if my head gasket is blown?

Answer: You can tell if your head gasket is blown by looking for several obvious signs. Common symptoms include white smoke coming from the exhaust, milky or foamy oil, unexplained coolant leaking without an obvious cause, engine overheating, engine stalling, misfires and decreased engine performance. Sometimes, you may also see bubbles in the radiator or coolant reservoir, which means exhaust gases are getting into the cooling system. Checking for these symptoms in a timely manner can prevent serious damage to your engine.

Q2. Can a blown head gasket be repaired without replacing the engine?

Answer: Yes, in many cases a blown head gasket can be repaired without replacing the entire engine. If the damage is discovered in time, mechanics can remove the cylinder head and replace the gasket and check for any wear or damage to the engine components. However, if the engine has overheated or the cylinder head is cracked or bent, it may require additional repairs or the entire engine may need to be replaced. Early diagnosis is important to avoid major expenses.

Q3. Is it safe to drive with a blown head gasket?

Answer: It is generally not safe to drive with a blown head gasket. Driving can worsen the damage as coolant and oil may leak out, causing the engine to overheat or jam. Even short trips can increase the risk of bent cylinder heads, damaged pistons, or other internal engine problems. It is best to stop driving immediately if symptoms appear and have the car checked by a professional mechanic.

Q4. How much does a blown head gasket repair cost?

Answer: The cost of repairing a blown head gasket can vary depending on the make and model of your car, the extent of the damage and labor costs. On average, replacing the gasket alone can cost several hundred to a thousand dollars. If the cylinder head is bent, cracked, or other engine components are damaged, repair costs can be much higher, sometimes requiring the entire engine to be rebuilt or replaced. Early detection and repair usually saves a lot of money compared to waiting until the problem is serious.

Q5. Can regular maintenance prevent a blown head gasket?

Answer: Yes, regular maintenance can prevent a blown head gasket. Regular coolant flushes can remove rust and debris that can affect the cooling system. Checking the engine temperature and responding promptly to overheating problems can reduce the stress on the gasket. Ensuring that the head bolts are torqued properly and that the right type of oil and coolant is used also helps keep the engine healthy. Regular care and monitoring can increase the life of the head gasket and reduce the chance of sudden engine failure.

Q6. How long can a car run with a blown head gasket?

Answer: How long a car can run with a blown head gasket depends on the severity of the damage. Some minor leaks may allow the car to run for a short time, but most engines begin to overheat, lose power or suffer internal damage after only a few miles. Continuing to drive a car with a blown gasket can cause irreversible damage to the engine, so it is advisable to stop using the car and have it repaired immediately.

Q7. What is the difference between a blown head gasket and a cracked engine block?

Answer: A blown head gasket is caused by a breakdown of the seal between the cylinder head and the engine block, allowing coolant, oil or combustion gases to leak out. On the other hand, a cracked engine block causes actual physical damage to the metal of the engine. While both can cause the engine to overheat and perform poorly, a cracked block is usually more serious and often requires the entire engine to be replaced. A professional mechanic can differentiate between the two using diagnostic tests such as a compression test, chemical tests and visual inspection.

Q8. Can I check for a blown head gasket at home?

Answer: Yes, there are several DIY tests that can indicate a blown head gasket. You can check for a milky residue in the oil cap, inspect the exhaust smoke for unusual colors, monitor the coolant level for unexplained loss and check for bubbles in the radiator. Other home tests include a compression check or the use of a chemical block test kit to detect exhaust gases in the coolant. While these tests can help you identify problems early, confirming a blown head gasket usually requires professional diagnosis for accurate results.

References:

[1] Analysis of Causes of Engine Overheating due to Cooling System Failure Using Pareto Principle

https://www.ijettjournal.org/2016/volume-36/number-5/IJETT-V36P245.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.