Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Yes, the paint protection film literally works like a transparent armor that provides protection to your car’s paint from small stones, harmful sunlight and dirt as well, as these things have the capability to slowly damage the car paint.

Shockingly, it was first developed for the military use, as to provide protection to the helicopter’s blades from debris; and today it is widely famous and used on the modern cars to keep the paint safe and new-looking.

Plus, it is true that PPF actually helps by guarding the car against stone chips, possible light scratches, road debris, insect stains, bird droppings, UV rays and other harsh weather conditions as well.

Even, you would be pleased to know that most of the high-quality PPF are made from the advanced flexible materials that can absorb the impact and return to their original shape as well, which literally helps it to reduce the visible marks over the period of time.

So, whenever you apply it in the clean and fully prepared surface, then you’ll see that PPF formed a tight bond with the paint without damaging it anyhow.

Now, this guide is to show you the correct way on How to Apply Paint Protection Film on Car, so that you can easily preserve the resale value.

Moreover, this paint also slow down paint fading, reduces the risk of the rust which is caused by the chipped paint and even it keeps the factory finish truly intact.

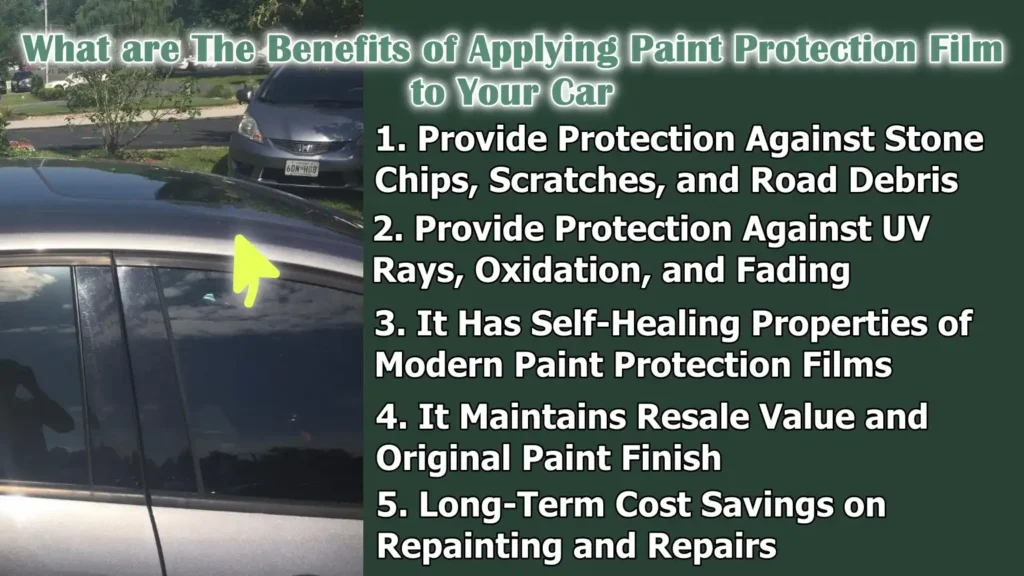

What are The Benefits of Applying Paint Protection Film to Your Car

1. Provide Protection Against Stone Chips, Scratches and Road Debris

Paint protection film creates a strong yet flexible layer over the car’s paint, absorbing the impact of small stones, gravel, sand and other road debris.

When driving on highways or rough roads, small stones are often kicked up by other vehicles, which can chip the paint and expose the underlying metal.

PPF helps mitigate this damage by absorbing the impact itself instead of the paint.

It also protects against minor scratches from car washes, tree branches, keys, or everyday contact.

By covering high-impact areas such as the hood, bumpers, mirrors and doors, the film helps keep the paint surface smooth and new-looking for longer.

2. Provide Protection Against UV Rays, Oxidation and Fading

Sunlight is one of the biggest causes of car paint fading over time.

Ultraviolet (UV) rays gradually break down the paint’s clear coat, leading to a loss of shine, fading and discoloration.

Paint protection film acts as a barrier that blocks or reduces the amount of UV rays reaching the paint surface.

This slows down the oxidation process, preventing the paint from losing its luster and vibrancy.

By minimizing sun damage, PPF helps the car maintain its original color and glossy finish even after years of being parked outdoors and driven regularly.

3. It Has Self-Healing Properties of Modern Paint Protection Films

Many modern paint protection films are designed with a self-healing feature, meaning they can automatically repair minor scratches on the surface.

Small scratches and swirl marks from washing or wiping often disappear when the film is exposed to the heat of sunlight or warm water.

This is because the film’s top layer is flexible and can return to its original shape.

As a result, the car remains clean and smooth without requiring frequent polishing or repairs.

This feature is specially beneficial for vehicles used daily, which are subject to regular wear and tear.

4. It Maintains Resale Value and Original Paint Finish

The original factory paint is one of the most crucial factors affecting a car’s resale value.

Cars with damaged, faded, or scratched paint often appear old and poorly maintained, which can significantly reduce their market value.

Paint protection film helps preserve the original paint by preventing damage before it occurs.

When the film is properly removed, the paint underneath often looks brand new.

This makes the car more attractive to potential buyers and allows owners to receive a better resale or trade-in value.

5. Long-Term Cost Savings on Repainting and Repairs

While paint protection film has an initial cost, it can save money in the long run.

Repairing stone chips, repainting panels, or fixing deep scratches can be expensive and may not always perfectly match the original factory finish.

PPF reduces the need for frequent touch-ups, repainting and paint correction work.

By protecting the paint from everyday damage, the film lowers maintenance costs over time and helps car owners avoid costly paint repairs in the future.

What are The Types of Paint Protection Film Available

1. Clear Paint Protection Film

Clear paint protection film is the most common and widely used type of PPF.

It is designed to be virtually invisible once applied, leaving the car’s original paint color, gloss and finish unchanged.

This type of film is ideal for car owners who want robust protection without altering the vehicle’s appearance.

Clear PPF protects against stone chips, minor scratches, road debris, insect splatters and minor chemical stains.

Because it blends seamlessly with the paint, it is often used on high-impact areas such as the front bumper, hood, mirrors and door edges, preserving the car’s factory look.

2. Matte and Satin Finish Paint Protection Film

Matte and satin finish paint protection films are designed for car owners who desire both protection and a distinctive visual style.

These films reduce glare and give the paint a smooth, muted look, while still providing the same level of protection as clear PPF.

Matte PPF is commonly used on cars with factory matte paint to prevent uneven gloss and damage, while satin PPF offers a balanced look between matte and glossy finishes.

These films help protect the paint from scratches, fading and stains, while maintaining a consistent finish that is difficult to achieve with repainting alone.

3. Pre-Cut Paint Protection Film Kits vs Bulk Roll Film

Pre-cut paint protection film kits are computer-designed to match specific car models and body panels.

They offer precise coverage with minimal trimming, reducing the risk of cutting into the paint during installation.

These kits are often easier for beginners and provide consistent results.

Bulk roll film, on the other hand, comes in large sheets that must be measured and cut during installation.

This option offers greater flexibility and can provide more seamless coverage, specially on custom or complex panels.

However, it requires more skill and experience to achieve a clean and secure finish.

4. Thermoplastic Polyurethane/TPU vs Older Film Types

Most modern paint protection films are made from thermoplastic polyurethane, known for its flexibility, durability and impact resistance.

TPU-based films can stretch and conform to curved surfaces while absorbing the impact of small stones and debris.

Older types of films, often made from basic plastic materials, were more rigid and more prone to yellowing, cracking, or peeling over time.

TPU films also offer better clarity, a longer lifespan and superior resistance to heat and environmental damage, making them more reliable for long-term paint protection.

5. Thickness Levels and Their Impact on Protection

Paint protection films come in varying thickness levels, which directly impacts their level of protection.

Thicker films offer better protection against stone chips and deep scratches because they can absorb more impact before the damage reaches the paint.

Thinner films still provide protection against light scratches and environmental damage, but may not be as effective against heavier impacts.

Choosing the right thickness depends on driving conditions, road quality and the level of protection desired by the car owner.

A balanced thickness is often preferred as it provides robust protection while maintaining a smooth and natural appearance on the car’s surface.

Tools

| Tool / Material Name | What It Is | Main Purpose During Installation |

|---|---|---|

| Paint Protection Film (Pre-Cut or Bulk) | A transparent or finish-type protective sheet designed to be adhered over a car’s paint. | It protects and protects the painted surface from damage. |

| Slip Solution | A water-based mixture that allows the film to be easily applied over the paint. | Helps to position and align the film before sticking. |

| Tack Solution | A strong water-based mixture with superior hold. | This helps the edges and corners adhere firmly to the paint. |

| Spray Bottles | Handheld bottles are used to spray liquids evenly. | Anti-slip and adhesive solutions can be easily applied. |

| Microfiber Towels | Soft, lint-free cleaning cloths. | This keeps the surface clean and prevents water from entering during installation. |

| Soft-Edge Squeegee | A flat tool with a flexible and soft edge. | This allows water and air to escape from under the film. |

| Heat Gun or Hair Dryer | A device that blows hot air. | This softens the film so it can stretch and fit into curved shapes. |

| Precision Knife | A sharp cutting tool with a thin blade. | This cuts off the excess film around the edges and panels. |

| Knife Blade Safety Practices | Safe methods are used when cutting the film. | This prevents damage to the paint and prevents injury to the hands. |

How to Prepare the Car’s Surface Before Applying Paint Protection Film

1. Thorough Washing to Remove Dirt and Contaminants

Before applying paint protection film, the car should be thoroughly washed to remove loose dirt, dust, mud and road grime.

Even small particles of dirt on the surface can get trapped under the film and create visible bumps or imperfections.

Washing helps clean areas like panel edges, badges and gaps where dirt often hides.

A clean surface helps the film lay flat on the paint and reduces the risk of bubbles or poor adhesion.

This step is crucial because the paint protection film adheres directly to the paint and any dirt can weaken the bond and affect the final appearance.

2. Using a Clay Bar to Remove Bonded Contaminants

After washing, some dirt and contaminants may still be bonded to the paint and cannot be removed with soap alone.

These bonded particles often come from brake dust, industrial fallout, tree sap, or road tar.

Using a clay bar helps gently lift these particles from the paint surface, leaving the surface smooth to the touch.

A smooth surface is important because the paint protection film requires direct and even contact with the paint to adhere properly.

If these particles are not removed, they can create raised spots under the film and compromise both the appearance and durability.

3. Paint Correction to Remove Swirl Marks and Scratches

Paint protection film does not hide paint imperfections; instead, it can make them more noticeable.

Swirl marks, light scratches and dull areas should be corrected before applying the film.

Paint correction involves polishing to restore the paint’s shine and smoothness.

This step helps ensure the paint looks clean and uniform before the film is applied.

As PPF is designed to remain on the car for years, correcting the paint beforehand helps maintain a better-looking finish and results in a better overall outcome.

3. Degreasing the Surface for Proper Adhesion

Even after washing and polishing, oil, wax residue, or polishing compounds can remain on the paint surface.

These substances can prevent the film from adhering properly.

Degreasing the surface removes these invisible layers and allows the adhesive side of the paint protection film to bond directly to the paint.

Proper adhesion is crucial to prevent edges from lifting, peeling, or the film failing prematurely.

A clean and oil-free surface helps the film stay secure and last longer.

4. The Importance of Working in a Dust-Free Environment

A clean and dust-free environment is essential for applying paint protection film.

Dust particles in the air can settle on the paint or film during installation and become trapped underneath.

Once trapped, these particles cannot be removed without removing the film.

A controlled indoor environment minimizes the chance of contamination and helps achieve a smooth and professional finish.

Working in a clean environment improves the clarity, adhesion and longevity of the paint protection film.

How to Apply Paint Protection Film on Car – Easy Process

1. Measuring and Positioning the Film Correctly

The first step in applying paint protection film is to measure the film so that it precisely covers the desired panel.

Accurate measurements help ensure that the film reaches all exposed areas, leaving no gaps or requiring excessive trimming later.

When applying the film to the car, it should be gently placed on the surface to check alignment with the body lines and edges.

Correct positioning at this stage minimizes errors, prevents overstretching the film and helps achieve a clean and natural look once the film is fully applied.

2. Spraying Slip Solution to Enhance Film Mobility

Before application, a slip solution is sprayed onto both the paint surface and the adhesive side of the film.

This solution creates a thin layer of moisture that allows the film to slide easily on the paint.

This ability to reposition the film is crucial as it provides ample time to adjust placement and correct alignment without the film immediately adhering.

Without the slip solution, the film can stick too quickly, making repositioning difficult and increasing the risk of wrinkles or uneven coverage.

3. Aligning the Film with Body Panels and Edges

Once the film is on the surface, careful alignment is necessary to match the contours of the car’s panels.

The film should follow the natural body lines, curves and edges to ensure complete and uniform coverage.

Proper alignment helps prevent visible seams and reduces tension in the film.

Taking the time to properly align the film improves both the aesthetics and durability, as a poorly aligned film can lift at the edges or wear unevenly over time.

4. Using a Squeegee to Remove Air Bubbles and Moisture

After alignment, a soft-edged squeegee is used to press the film onto the paint and expel any trapped air and moisture.

This process starts from the center of the panel and moves outward towards the edges.

Removing air and water is crucial because trapped moisture can weaken the adhesive and cause bubbles.

Proper squeegee technique helps keep the film flat against the paint, resulting in a smooth, seamless finish that blends seamlessly with the car’s surface.

5. Applying Heat to Stretch and Shape the Film

Heat is applied using a heat gun or hairdryer to soften the film, allowing it to stretch slightly and conform to the shape of curved or complex areas.

Gentle heat makes the film more pliable, enabling it to wrap smoothly around edges, corners and contours without creasing.

This step must be done carefully, as excessive heat can damage the film.

Using the correct amount of heat ensures the film perfectly fits the panel’s shape and maintains strong contact with the paint.

6. Securing Edges and Corners for Long-Lasting Durability

The final step focuses on securing the edges and corners of the film.

These areas are most vulnerable to peeling if not properly set.

A tack solution is often used to enhance adhesion in these areas.

Firmly pressing and sealing the edges helps prevent dirt and water from getting under the film.

Well-secured edges and corners extend the lifespan of the paint protection film and keep it looking clean and intact during daily driving and washing.

How to Apply Paint Protection Film to Different Car Panels

1. Hood and Front Bumper Installation Tips

The hood and front bumper are the most vulnerable to damage from rocks, insects and road debris, making them the most challenging areas for paint protection film application.

The hood typically has a large, flat surface, requiring careful application of the film to avoid visible lines or uneven edges.

The front bumper is more complex, featuring curves, air vents and sharp edges.

Extra care is needed to gently stretch and heat-mold the film so it conforms perfectly without wrinkles.

Proper coverage on these panels minimizes the risk of paint damage and keeps the front of the car looking pristine for longer.

2. Fender and Side Mirror Installation Techniques

Fenders and side mirrors are frequently impacted by debris kicked up by tires and passing vehicles.

These panels are usually curved, meaning the film must be stretched evenly to avoid stress marks.

Side mirrors are small but intricate, requiring precise placement and controlled heat to ensure the film adheres smoothly around the edges.

Proper application in these areas helps protect against scratches from parking, narrow streets and roadside objects, which are common causes of paint damage.

3. Doors, Door Edges and Handle Cups

Doors are constantly in contact with hands, keys, shoes and adjacent vehicles, making them susceptible to scratches and scuffs.

Applying paint protection film to the door panels helps mitigate wear and tear from daily use.

Door edges benefit greatly from PPF, as they are easily scratched when opening doors in tight spaces.

Handle cups, the area behind the door handles, are often scratched by fingernails and rings.

Covering these areas with film ensures a clean and smooth finish even after regular use.

4. Considerations for the Roof and Trunk Lid

The roof and trunk lid are frequently exposed to harsh sunlight, bird droppings, tree sap and environmental debris.

Applying paint protection film to these panels helps minimize fading from prolonged sun exposure and protects against stains that can damage the clear coat.

These areas typically have flat surfaces, but proper alignment is still crucial to avoid visible seams.

Protecting the roof and trunk lid helps maintain a consistent paint condition across the entire car.

5. Headlight and Fog Light Protection

Headlights and fog lights are made of clear plastic that can become hazy or scratched over time due to exposure to road debris and UV rays.

Applying paint protection film to these surfaces helps prevent yellowing, pitting and minor cracks.

The film remains clear and allows light to pass through without reducing brightness.

Protecting the headlights and fog lights improves visibility, preserves the car’s appearance and helps avoid costly replacements or repairs in the future.

What are The Common Mistakes to Avoid When Applying Paint Protection Film

1. Applying the Film to Dirty or Damaged Paint

One of the most common mistakes when applying paint protection film is applying it to paint that hasn’t been properly cleaned or is already damaged.

Any dirt, dust, wax, oil, or polish residue left on the surface can get trapped under the film and remain visible even after application.

Scratches and swirl marks will not be hidden by the film and may even look worse after it’s sealed.

Proper cleaning and paint preparation are crucial because the film adheres directly to the paint and any imperfections present before application will remain for the entire lifespan of the film.

2. Overstretching the Film

Paint protection film is flexible, but overstretching it can lead to problems.

Overstretching thins the film in certain areas, reducing its ability to protect the paint.

This can also cause stress marks, an uneven appearance and premature peeling at the edges.

When the film is stretched beyond its limits, it can gradually shrink over time, causing corners and edges to lift.

Gentle stretching with controlled heat ensures the film adheres properly without compromising its protective strength.

3. Trapping Air Bubbles or Dust Particles

Air bubbles and dust particles trapped under the film can ruin the final look and compromise adhesion.

Dust can be introduced during application if the workspace is not clean or if the tools and hands are not properly prepared.

Once the film is applied, these particles cannot be removed without removing the film itself.

Air bubbles can also trap moisture, weakening the adhesive over time.

Taking the time to properly squeegee out air and water using the correct technique will result in a smooth and long-lasting finish.

4. Cutting the Film Directly on Painted Surfaces

Cutting paint protection film directly on the car’s painted surface is a risky mistake.

Even a slight slip of the blade can leave permanent scratches in the paint or cut through the clear coat.

These marks can diminish the car’s value and may require expensive repainting to fix.

Safer installation methods involve using pre-cut film or carefully trimming the film away from the paint.

Protecting the paint during the cutting process is just as crucial as applying the film itself.

5. Rushing the Curing Process

The curing process allows the adhesive on the paint protection film to fully bond with the paint.

Rushing this step, such as washing the car too soon, driving in heavy rain, or applying pressure to the film, can lead to problems like edge peeling and reduced durability.

Trapped moisture from the installation process needs time to evaporate naturally.

Allowing sufficient curing time ensures a strong bond, a clean look and long-lasting performance of the film.

Read More:

How to Dry, Cure and Perform Post-Installation Care of Paint Protection Film

1. Initial Curing Time and Temperature Requirements

After applying paint protection film, it needs time to dry and cure so that the adhesive fully bonds with the paint.

During this time, any trapped moisture beneath the film gradually evaporates and the film sets in its final position.

Warm and consistent temperatures aid the curing process as the adhesive performs best when it is neither too cold nor too hot.

In colder conditions, curing may take longer, while excessive heat can cause the film to shift if it hasn’t fully set.

Allowing the film to cure naturally helps prevent edge lifting and ensures a strong and uniform bond.

2. When Can the Car Be Driven After Installation?

In most cases, the car can be driven carefully after installation, once the film has set enough to remain in place.

Normal driving is usually safe, but aggressive driving, high speeds, or long highway trips should be avoided during the initial curing stage.

Wind pressure and road debris can affect newly applied film if it hasn’t fully adhered.

Driving gently for the first few days protects the film and reduces the risk of edge lifting or moisture trapping.

3. Proper Washing Techniques After Paint Protection Film Installation

Properly washing your car after paint protection film installation is crucial for its appearance and longevity.

It’s best to wait until the film is fully cured before washing the vehicle.

Once it’s safe to wash, gentle hand washing with clean water and a mild car shampoo helps keep the film clean without damaging it.

Soft washing tools minimize the chances of scratching the film’s surface.

Proper washing helps remove dirt, insects and road grime, keeping the film clean and smooth.

4. Avoid pressure washing near the edges initially.

High-pressure water can be damaging to newly applied paint protection film, specially around the edges and corners.

The forceful water can get under the film and weaken the adhesive before it has fully cured.

In the initial days after installation, it’s crucial to avoid directing a stream of water at the film’s edges.

This helps prevent lifting, peeling, or separation.

Once the film has fully adhered, it becomes more resistant to normal washing methods.

5. How long does paint protection film typically last?

The lifespan of paint protection film depends on the quality of the film, the installation method and how it is cared for.

High-quality films can last for many years, maintaining their clarity and protective properties.

Regular cleaning and proper care can prevent staining, discoloration and edge deterioration.

Over time, the film continues to protect the underlying paint and when removed correctly, the original paint is usually in good condition.

Proper care after installation plays a significant role in how long the film remains effective.

How to Maintain Tips to Extend the Life of Paint Protection Film

Additionally, there’s market research that shows that, the global paint protection film industry is actually expanding in the rapid way, as its demand is increasing from the automotive sector; also TPU-based films are actually leading this growth race as they have really balance impact resistance, flexibility and optical clarity as well, that makes them ideal for daily driving conditions.[¹]

1. Recommended Cleaning Products and Methods

Proper cleaning plays a crucial role in keeping paint protection film clean and effective for a long time.

Car wash soaps designed for automotive surfaces help clean the film without damaging its top layer.

Using clean water and soft washing tools minimizes the risk of scratching the surface.

Harsh chemicals and strong cleaners can gradually weaken the film and reduce its clarity.

Regular, gentle cleaning removes dirt before it accumulates, keeping the film smooth and transparent.

2. Removing Stains, Insect Splatter and Bird Droppings

Insect splatter, bird droppings and road tar can stain the film if left for too long.

These substances are often acidic and can damage the surface when exposed to heat and sunlight.

Cleaning them as soon as possible prevents permanent staining.

Using warm water and gentle cleaning methods softens dried residue, making it easier to remove without scratching the film.

Prompt removal of these stains preserves both the film’s appearance and protective qualities.

3. Preventing Yellowing and Edge Lifting

Yellowing and edge lifting are common problems when paint protection film is not properly maintained.

Constant exposure to sunlight, pollution and harsh chemicals can cause discoloration over time.

Keeping the film clean and avoiding strong chemical cleaners reduces this risk.

Edge lifting often occurs when dirt and moisture accumulate along the film’s edges.

Regular cleaning around the edges and avoiding aggressive washing methods ensures that the film remains securely adhered and looks clean.

4. Periodic Inspections and Touch-Ups

Regular inspections help identify minor issues before they escalate into major problems.

Checking for peeling edges, trapped debris, or surface blemishes allows for timely repairs.

Minor touch-ups or resealing the edges can extend the film’s lifespan.

Addressing problems promptly prevents further damage and ensures the film continues to protect the paint effectively.

Regular inspections are a simple habit with long-term benefits.

5. Combining Paint Protection Film with Ceramic Coating

Paint protection film can be safely combined with a ceramic coating for easier cleaning and a smoother surface.

Applying a ceramic coating over the film helps repel water, dirt and contaminants, making maintenance easier.

It also reduces staining and keeps the film cleaner for longer.

Using compatible products and following the correct curing times ensures that both layers work together without compromising protection or durability.

Know, Difference Between DIY Paint Protection Film Installation vs Professional Installation

1. Skill Level Required for DIY Installation

Installing paint protection film yourself requires patience, a steady hand and a good understanding of the installation process.

The film must be positioned correctly, aligned with the body panels and carefully stretched using controlled heat.

Minor mistakes, such as trapped dust, uneven stretching, or poor edge sealing, can affect both the appearance and durability.

DIY installation is more suitable for simple panels and smaller areas, but complex shapes like bumpers and mirrors can be challenging for beginners.

The process takes time to learn and the results often depend on practice and attention to detail.

2. Cost Comparison Between DIY and Professional Service

DIY paint protection film installation typically has a lower initial cost because you only pay for the film and basic tools.

However, mistakes during installation can lead to wasted material, requiring additional purchases or the removal and replacement of the film.

Professional installation costs more because it involves skilled technicians, specialized tools and a controlled environment.

While the initial cost is higher, professional work often reduces the risk of errors and rework, potentially saving money in the long run.

3. Differences in Quality, Warranty and Finish

Professional installation generally results in a cleaner finish with better alignment, smoother edges and fewer visible imperfections.

Trained installers work in a dust-free environment and follow proven techniques for long-lasting results.

Many professional services also offer warranties that cover issues such as peeling, bubbling, or discoloration.

DIY installation typically does not include a warranty and the final look can vary depending on the skill level.

The difference in finish quality can be significant, specially on larger or curved panels.

4. When is professional installation the better option?

Professional installation is often the better option for new cars, luxury vehicles, or when covering the entire body.

Difficult panels, sharp curves and intricate edges are easier to handle with experience and the right tools.

Choosing professional installation ensures that the paint is properly protected and there is no risk of damage during cutting or stretching.

For car owners who want long-lasting protection, a strong bond and a high-quality finish, professional installation offers greater reliability and peace of mind.

Basic Cost of Applying Paint Protection Film to a Car

1. Factors Affecting the Price of Paint Protection Film

The cost of applying paint protection film depends on several key factors.

The quality of the film plays a significant role, as thicker and more advanced films are typically more expensive.

The size and shape of the car also influence the price, as larger vehicles require more material and time.

Complex panels with curves, sharp edges and intricate shapes take longer to cover and increase labor costs.

The installation method, whether performed by a professional or as a DIY project, also impacts the final price.

A clean installation environment and skilled labor improve durability and appearance, adding to the value.

2. Partial Coverage vs Full-Body Coverage

Partial coverage focuses on high-impact areas such as the front bumper, hood, mirrors and fenders.

This option is less expensive and still provides robust protection to the areas most vulnerable to damage.

Full-body coverage protects every painted surface, offering maximum protection against scratches, chips and fading.

While full-body coverage is more expensive, it preserves the entire car’s paintwork in near-original condition.

The choice between partial and full coverage depends on driving habits, road conditions and how long the owner plans to keep the car.

3. Long-Term Value vs Initial Cost

Although the initial cost of paint protection film can be substantial, it can provide long-term value by reducing paint damage and repair expenses.

Repainting panels, fixing stone chips and repairing scratches can be costly and may diminish the car’s value if the original paint is altered.

PPF helps prevent this damage and preserves the factory finish.

Over time, the money saved on repairs and repainting can equal or exceed the initial investment in the film.

4. Typical Price Ranges for Different Car Sizes

The cost of paint protection film varies depending on the size of the vehicle and the level of coverage.

Smaller cars are generally less expensive because they require less film and labor.

Mid-size cars and sedans fall into the mid-price range, while larger vehicles such as SUVs and luxury cars are more expensive due to their size and complex panels.

Full-body coverage is significantly more expensive than partial coverage, but it provides complete protection.

Understanding these price differences helps car owners choose an option that suits both their budget and protection needs.

Conclusion – How to Apply Paint Protection Film on Car

It is true that, a car’s paint is always under attack when you drive them on the road, as there are small stones, chips, debris, water and insects that can scratch or dull the paint of your vehicle, which is why it becomes important to apply the PPF to prevent those paint damages.

As well as, in today’s driving conditions, vehicles are constantly exposed to a variety of risks, such as stone chips, road debris, sunlight, pollution and minor scratches that gradually damage the paint surface.

So, once the paint is damaged or faded, repairs can be expensive and often a factory-like finish cannot be fully restored.

Plus, paint protection film works by adding a clear, durable layer that absorbs everyday damage before it reaches the paint.

And, when you apply it to a properly prepared surface and maintained correctly, the film remains virtually invisible while providing continuous protection during driving, parking and washing.

Another major benefit of paint protection film is that it protects not only the vehicle’s appearance but also its value.

Original paint plays a significant role in resale and trade-in pricing.

Vehicles with clean, well-maintained paint often look newer and better cared for, increasing buyer confidence.

By preventing chips, scratches and fading, PPF helps keep the vehicle in a condition that reflects the owner’s meticulous care.

Over time, this protection can reduce the need for repainting, touch-ups and paint correction, helping to offset the initial installation cost.

Now, you can ask more related questions, by commenting below.

Frequently Asked Questions

Q1. What is paint protection film and how does it work?

Answer: Paint protection film is a transparent protective layer applied to a car’s painted surfaces. It works by absorbing damage from stone chips, minor scratches, road debris and environmental elements before they reach the paint. The film adheres directly to the paint and acts as a barrier, preserving the original finish while remaining virtually invisible. It’s designed to flex slightly upon impact and return to its original shape, minimizing visible marks.

Q2. Does paint protection film damage car paint?

Answer: When properly applied and removed, paint protection film does not damage car paint. In fact, it protects the underlying paint from daily wear and tear. When removed correctly, the paint beneath the film typically looks much better than paint of the same age that hasn’t been protected. Problems only arise if the paint is already damaged before installation or if the film is removed incorrectly.

Q3. How long does paint protection film last on a car?

Answer: The lifespan of paint protection film depends on the quality of the film, the quality of the installation and the maintenance. High-quality film, properly installed and well-maintained, can remain clear and effective for many years. Regular washing, avoiding harsh chemicals and checking the edges helps extend its lifespan. Over time, even as the film naturally ages, it continues to protect the paint.

Q4. Can paint protection film be applied to any car?

Answer: Paint protection film can be applied to almost any car, including new cars, older cars and even repainted vehicles. It works on sedans, SUVs, sports cars and luxury vehicles. The most important condition is that the painted surface must be clean and in good condition before application. Proper preparation ensures a strong bond and a good appearance.

Q5. Is paint protection film worth the cost?

Answer: Paint protection film is often worth the cost for car owners who want to protect their paint and reduce repair costs in the long run. Paint damage from stone chips and scratches can be expensive to repair and can decrease resale value. PPF helps prevent these problems before they occur. Over time, the savings on repainting and paint correction can offset the initial cost.

Q6. Can paint protection film self-heal scratches?

Answer: Many modern paint protection films have self-healing properties that allow them to repair minor scratches on the surface. When exposed to the heat of the sun or hot water, minor imperfections on the film’s surface disappear on their own. This feature helps keep the film looking clean and reduces the need for frequent polishing or replacement.

Q7. Does paint protection film change the look of the car?

Answer: Clear paint protection film is designed to be virtually invisible and does not alter the color or shine of the car’s paint. Matte or satin versions may change the look by reducing gloss, but clear film maintains the factory look. When properly applied, most people won’t even notice the film is there.

Q8. Can paint protection film be washed like normal paint?

Answer: Yes, paint protection film can be washed like normal car paint once it has fully cured. Gentle hand washing with a mild car shampoo is the safest method. Harsh washing methods and strong chemicals should be avoided, specially near the edges. Proper washing keeps the film clean and maintains its clarity.

Q9. Can paint protection film be removed later?

Answer: The paint protection film can be safely removed when needed. The removal process often involves using controlled heat, which softens the adhesive and allows the film to be removed without damaging the paint. When removed correctly, the paint underneath is usually in excellent condition and may even look newer than the exposed areas.

References:

[1] PAINT PROTECTION FILM MARKET SIZE AND SHARE ANALYSIS – GROWTH TRENDS AND FORECASTS (2025-2032)

https://www.coherentmarketinsights.com/industry-reports/paint-protection-film-market

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.