Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Basically, if the power steering system is properly bled then the fluid can flow in the free way, that keeps your steering wheel light, quiet and ideally responsive.

So, whenever air gets trapped inside the power steering system, as it can cause the irritating noises, jerky steering and even it can lead to the premature wear on the pump, which actually responsible for creating the hydraulic pressure that actually helps you to turn the wheel.

Also, there’s studies in automotive maintenance that shows that air bubbles can reduce hydraulic efficiency by up to the 25%, that makes the steering really harder and that puts more load on the components.

Not only this, most of the modern cars actually uses hydraulic power steering systems that circulate the fluid at the pressures between 800 to 2,000 psi, even a small amount of air can literally disrupt this pressure balance badly.

Yes, when you bleed the system at the regular time interval then it actually prevents damage to the pump and steering rack but also extends the life of the fluid as well, which can actually degrade from heat, contamination and moisture over the time.

Now, this is the guide on How to Bleed Power Steering Fluid that can truly restore smooth and truly reliable steering performance as well.

Tools

| Tool / Material | Simple Description (Easy Words) | Why It Is Needed |

|---|---|---|

| Power Steering Fluid (Recommended Type) | The special oil your car’s steering system uses. | Refills the system and replaces old or low fluid so the steering works smoothly. |

| Jack and Jack Stands | A jack lifts the car; jack stands keep the car safely raised. | Lifting the front wheels makes it easier to turn the steering wheel during bleeding. |

| Drain Pan | A wide container used to catch old fluid. | Prevents spills on the ground and keeps the workspace clean. |

| Turkey Baster or Fluid Extractor (Optional) | A simple hand tool that sucks out fluid from the reservoir. | Helps remove old, dirty fluid before adding fresh fluid. |

| Safety Gloves | Protective hand gloves. | Protects your skin from chemicals in the steering fluid. |

| Rags or Shop Towels | Cloth pieces used for wiping spills and keeping parts clean. | Helps clean accidental drips and keeps the work area safe. |

| Wrench Set | A set of tools for loosening or tightening nuts and bolts. | Needed if you must open a hose line, check clamps, or remove parts. |

What are The Basic Safety Precautions

1. Let the engine cool before starting.

It’s crucial to let the engine cool before working on the power steering system because the pump and reservoir can become very hot during driving.

Hot engine parts can easily cause burns and the steering fluid can reach temperatures exceeding 80–100°C, making it unsafe to open or check immediately.

Letting the engine cool also allows the fluid to settle, giving you a more accurate reading of the fluid level and preventing pressure buildup when you remove the reservoir cap.

Starting the engine when it’s cold can prevent injuries and provide more accurate results during the bleeding process.

2. Park the vehicle on a stable, level surface.

Working on a flat and stable surface is essential because it prevents the vehicle from rolling or rocking when you’re turning the steering wheel or working under the hood.

Power steering bleeding often involves turning the wheels left and right and if the car is jacked up, an uneven surface can tilt the car, rock it, or put excessive pressure on the jack stands.

A flat surface ensures proper weight distribution, safe wheel movement and more accurate fluid circulation.

This simple step reduces the risk of accidents and makes the entire process easier and safer.

3. Wear gloves to avoid skin irritation from the fluid.

Power steering fluid contains chemicals that can irritate the skin, cause dryness, or trigger an allergic reaction with prolonged contact.

Wearing gloves protects your hands from these chemicals and keeps your skin clean when handling hoses, caps and tools.

Many mechanics prefer nitrile gloves because they are oil-resistant and provide better grip.

Gloves also help prevent fluid from spilling onto interior or exterior car surfaces, which could damage or stain the paint.

Wearing gloves throughout the process protects your skin and allows you to work more comfortably.

4. Don’t run the engine dry without fluid in the reservoir.

Running the engine with little or no power steering fluid in the reservoir can seriously damage the pump, as it relies on fluid for both lubrication and cooling.

Without fluid, the pump can overheat, make a loud noise and suffer internal wear within minutes.

Air can also enter the system, causing stiff steering and requiring you to repeat the bleeding process.

Keeping the reservoir full throughout the process ensures the pump remains safe and hydraulic pressure remains stable.

This simple rule prevents costly repairs and keeps the system functioning properly.

How to Prepare the Vehicle First

1. Park the car on a level surface

Parking the car on a level surface is crucial because it ensures the vehicle remains stable and the weight is distributed evenly across all wheels.

When the ground is level, the power steering fluid inside the reservoir stays at its correct level, allowing you to get an accurate reading before bleeding the system.

A level surface also ensures the car doesn’t unexpectedly roll or shift while you’re turning the steering wheel from side to side during this process.

This simple step enhances safety, makes your work easier and helps the bleeding process function correctly because the fluid can flow through the system without tilting or accumulating in the wrong places.

2. Engage the parking brake

Engaging the parking brake adds another layer of safety by locking the rear wheels so the car cannot move while you are working.

Bleeding the power steering system often requires turning the steering wheel fully in both directions and this movement can cause slight forward or backward movement if the brake isn’t engaged.

The parking brake holds the car firmly in place, specially on slippery surfaces where tires might slide more easily.

This prevents accidents, protects you while you’re working near the wheels or reservoir and keeps the car stable throughout every step of the process.

3. Open the hood and locate the power steering reservoir

Opening the hood and locating the power steering reservoir helps you familiarize yourself with the part of the system you’ll be working on.

The reservoir is typically a small plastic or metal container connected by hoses that supply fluid to the power steering pump.

Locating it quickly allows you to check the fluid level, inspect for leaks and see if the fluid appears dirty or foamy, which could indicate trapped air or old fluid.

Knowing its location also helps you understand how power flows through the steering system, making the bleeding process easier, faster and more accurate.

4. Raise the front of the car using a jack and secure it with jack stands.

Raising the front of the car and securing it with jack stands is optional but highly recommended because it reduces the resistance from the tires when you turn the steering wheel.

With the front wheels off the ground, the steering system can rotate freely, allowing trapped air to escape more easily as you turn the wheel from side to side.

Using jack stands for safety is crucial, as a single jack cannot reliably support the car for an extended period.

This setup makes the bleeding process easier, safer and more effective, specially for beginners who want to minimize the effort required to turn the steering wheel while working.

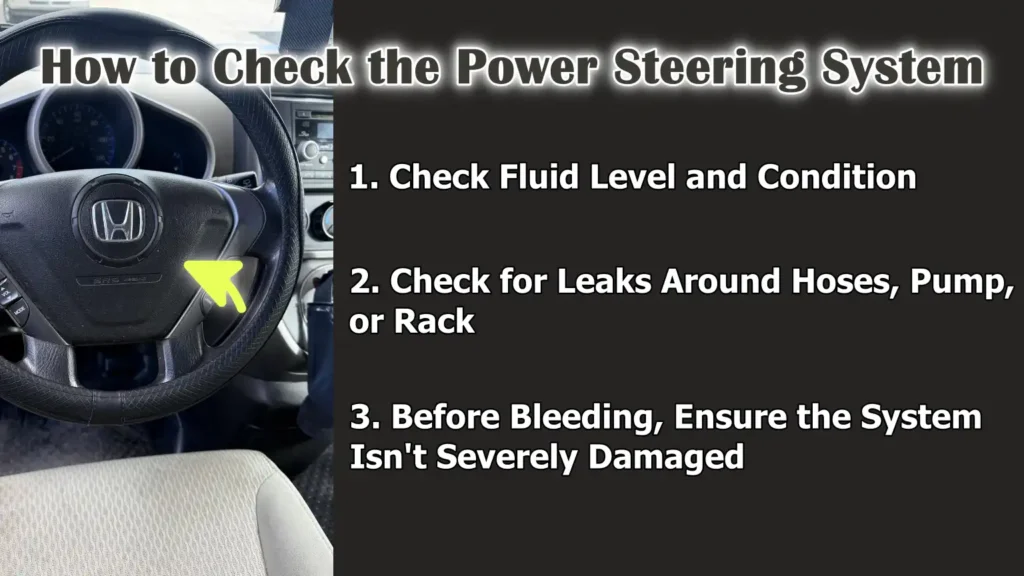

How to Check the Power Steering System

1. Check Fluid Level and Condition

Checking the fluid level and condition is one of the most crucial steps before bleeding the power steering system, as it tells you how well the system is currently functioning.

The power steering fluid should be between the “MIN” and “MAX” marks on the reservoir and its color should be clear, typically red, amber, or light brown depending on the type.

If the fluid appears dark, smells burnt, or looks milky or frothy, it may contain air, moisture, or contaminants that can compromise the hydraulic pressure necessary for smooth steering.

Low fluid levels can also allow air into the pump, leading to reduced lubrication and causing noisy or stiff steering.

By carefully inspecting the fluid, you identify potential problems, understand the system’s condition and ensure that the bleeding process will be effective and safe.

2. Check for Leaks Around Hoses, Pump, or Rack

Checking for leaks around the hoses, power steering pump and steering rack is essential because even a small leak can reintroduce air into the system after bleeding.

Power steering operates under high pressure, often between 800 and 2,000 psi, so weak or cracked hoses can leak fluid and also allow air to enter the system.

Common leak points include hose connections, pump seals and the rubber boots on the steering rack, which can deteriorate over time due to heat and pressure.

Leaks not only reduce fluid levels but can also cause pump wear, noisy steering and erratic steering response.

By thoroughly inspecting these areas before bleeding, you ensure the system can maintain proper pressure and prevent the need for repeated bleeding later.

3. Before Bleeding, Ensure the System Isn’t Severely Damaged

Before bleeding the power steering system, it’s crucial to ensure that it’s not severely damaged, as bleeding cannot fix mechanical problems such as a faulty pump, worn rack, or broken belt.

The power steering pump relies on internal vanes to generate hydraulic pressure and if these parts are worn, bleeding will not restore normal steering feel.

Similarly, a faulty steering rack can cause uneven movement, fluid leaks, or grinding noises, even if there is no air in the system.

If you notice loud grinding noises, excessively stiff steering, or rapid fluid leaks, these symptoms may indicate mechanical problems that require repair rather than bleeding.

By ensuring the system is in good working order, you prevent further damage and ensure that the bleeding process is effective.

How to Manually Bleed Power Steering Fluid – Engine-Off

1. Fill the Reservoir to the Correct Level

Filling the power steering reservoir to the correct level is the first and most crucial step in the manual bleeding process because the system requires sufficient fluid to expel trapped air from the lines.

Power steering systems operate using hydraulic pressure and when the fluid level is low, the pump can draw in air instead of fluid, leading to foaming, noise and reduced steering control.

The correct level is marked on the reservoir, usually with “MIN” and “MAX” lines and it’s essential to use only the fluid recommended by the manufacturer, as different systems use different formulations for lubrication and pressure stability.

Starting with a full reservoir ensures that as air rises and escapes, it is replaced by fresh fluid, allowing the system to maintain consistent pressure without drawing in new air.

2. Slowly Turn the Steering Wheel from Lock to Lock

Slowly turning the steering wheel from one end to the other, known as lock-to-lock, helps to dislodge air from the power steering lines and push it towards the reservoir where it can escape.

This movement forces the fluid to circulate through the pump, hoses and steering rack, even with the engine off.

The slow movement is crucial because rapid movements can create turbulence within the system, causing the air to break down into smaller bubbles that take longer to expel.

A slow, deliberate movement from left to right allows larger pockets of air to rise gradually, increasing the effectiveness of the bleeding process and reducing unnecessary stress on the steering components.

3. Repeat this process several times to push the air towards the reservoir.

Repeating the lock-to-lock turning process several times is crucial because the power steering system has numerous passages and chambers where air can become trapped, specially after repairs or fluid changes.

Each cycle moves the fluid further through the system and pushes more air upwards into the reservoir.

Because air is lighter than the fluid, it naturally rises as the fluid circulates through the lines.

Performing multiple cycles ensures that even small pockets of air hidden in bends, valves, or within the steering rack have a chance to escape.

This repetitive process helps restore consistent hydraulic pressure and prepares the system for normal operation.

4. Check and refill the fluid level as air is released.

Checking and refilling the fluid level during this process is essential, as the fluid level in the reservoir will drop as air is purged from the lines.

If the level drops too low, the system can draw in more air, rendering your efforts useless and requiring you to repeat the bleeding steps.

Keeping the reservoir properly filled ensures a continuous supply of fluid to the pump and prevents damage from the system running dry.

Observing the fluid while working may also allow you to see bubbles rising, a clear indication that trapped air is being released.

Adding small amounts of fluid as needed keeps the process smooth and protects the power steering components.

5. Continue until no more bubbles are visible in the reservoir.

Continuing the manual bleeding process until no more bubbles are visible in the reservoir is the final confirmation that all trapped air has been successfully removed from the system.

When the fluid becomes stable, clear and free of bubbles, it means the hydraulic pressure can now stabilize and the steering components can function normally.

A bubble-free reservoir indicates that the system’s hoses and pump contain only fluid, which helps restore smooth, quiet and responsive steering.

This stage also prevents future problems such as loud noises, jerky steering wheel movement, or pump overheating.

Once the fluid is stable and no air pockets are visible, the manual bleeding process is complete and the system is ready for a final check.

How to Perform Engine-On Bleeding Method

1. Start the engine and let it idle.

Starting the engine and letting it idle allows the power steering pump to begin circulating fluid through the system at a steady, controlled speed.

When the engine is idling, the pump operates at a lower RPM, which is ideal for bleeding air because it generates enough pressure to move the fluid smoothly without creating turbulence.

Higher engine speeds can break the air into smaller bubbles, making them harder to remove, so the idle speed provides the right balance for efficient bleeding.

As the pump begins to operate, any remaining pockets of air in the hoses and steering rack begin to move towards the reservoir, where they can rise to the surface and escape.

Letting the engine idle for a few minutes also slightly warms the fluid, reducing its viscosity and helping it flow more easily through the narrow passages within the system.

2. Slowly turn the steering wheel from left to right.

Slowly turning the steering wheel from left to right helps the pressurized fluid reach all parts of the steering system, including the internal chambers of the rack and pinion or steering box.

This movement pushes trapped air upwards as the hydraulic pressure increases within the lines.

Turning the wheel slowly is crucial because sudden, rapid movements can cause turbulence in the fluid, breaking up the air and potentially trapping it instead of allowing it to reach the reservoir.

The slow, full range of steering movement helps the air move smoothly upwards and ensures the pump maintains consistent pressure.

This slow left-to-right motion also allows you to feel for changes in steering effort, which is a good indicator of whether air is still present.

3. Observe the fluid flow and check for bubbles.

Observing the fluid while the system is running is crucial because it tells you whether air is still circulating.

When air is passing through the lines, you may see bubbles, foam, or swirling patterns in the reservoir.

Power steering fluid should typically appear calm and clear when there is no air in the system.

Observing the flow helps you track progress and also alerts you to problems such as low fluid levels, pump cavitation, or contamination.

Seeing bubbles rise to the surface confirms that the bleeding process is working correctly.

As the process continues, the fluid in the reservoir should become smoother and more stable, indicating that the hydraulic pressure is balancing and air is being purged from the system.

4. Maintain the fluid level to prevent air from re-entering.

Maintaining the fluid level is critical because a low level in the reservoir can allow new air to enter the pump, undoing all the work done during the bleeding process.

The power steering pump relies on the fluid for lubrication, pressure generation and cooling, so even a short period of low fluid can introduce air back into the system.

Keeping the reservoir filled to the recommended line ensures that the pump always has enough fluid to send to the steering components.

Adding small amounts of fluid as needed helps prevent cavitation, which is the process of small air bubbles forming due to low fluid levels.

By carefully monitoring the level throughout this process, you protect the pump and allow the bleeding procedure to proceed smoothly and efficiently.

5. Continue until the steering is smooth and the fluid is stable.

With the engine running, continue the bleeding process until the steering becomes smooth and the fluid level stabilizes.

This ensures that all air has been completely removed from the system.

Once bleeding is complete, the steering wheel will feel consistent, light and free of any jerks or stiffness.

The fluid in the reservoir will appear calm, without any bubbles, foam, or swirling motion, indicating that the hydraulic pressure is stable and the pump is fully primed.

Smooth steering is a sign that the power steering rack is receiving equal pressure on both sides, allowing it to function correctly.

Once the engine is idling and the steering feels normal and the fluid is clear and stable, the system is properly bled and ready for regular driving.

Read More:

What to Check In The Final System

1. Re-check and Top Up Fluid Level

Re-checking the fluid level after the bleeding process is crucial because removing air can lower the fluid level in the reservoir as the system becomes fully filled.

In a power steering system, the fluid is not only in the reservoir but also in the pump, hoses and steering rack, so the actual required amount is only known once all the air has been removed.

If the fluid level is even slightly low, the pump can draw in air during driving, leading to cavitation and reduced steering performance.

Topping up to the correct level ensures consistent hydraulic pressure in the system, keeps the pump lubricated and prevents future noises or jerks.

This final check also helps confirm that the bleeding process was completely successful and that the steering system has the correct amount of fluid for proper operation.

2. Re-check for Leaks

Re-checking the system for leaks is essential because the hydraulic pressure generated during bleeding can reveal weak points in hoses, seals, or fittings that might not have been apparent before.

Power steering fluid leaks often occur around hose clamps, pump seals and the steering rack and even a small drip over time can introduce air back into the system.

Leaks not only reduce the fluid level but can also put extra strain on the pump, leading to premature failure.

Re-checking all visible components after bleeding ensures that the system can maintain pressure, remain clean and operate smoothly.

By confirming that no new leaks have developed, you prevent future steering problems and extend the lifespan of the entire system.

3. If the vehicle was lifted, lower it

If the vehicle was previously lifted, safely lowering it is a crucial step because the wheels must return to their normal loaded position before the final steering test.

When the car is lifted, the wheels rotate more easily, making the bleeding process simpler, but this doesn’t accurately reflect how the steering will feel on the road.

Once the bleeding is complete, lowering the vehicle allows the suspension and steering components to settle back into their natural alignment under the full weight of the car.

This provides a more accurate representation of steering effort, noise and responsiveness.

Ensuring the vehicle is properly lowered and stable before driving also prevents accidents and protects the steering system from unnecessary stress.

4. The steering should be quiet and responsive during a short test drive.

The final way to confirm that the power steering system is fully vented and functioning correctly is with a short test drive.

During the test drive, the steering should feel smooth, light and consistent, without any unusual noises, grinding, or jerking.

A properly bled system allows the fluid to flow evenly under load, ensuring the pump maintains consistent pressure even when cornering or parking at low speeds.

Paying attention to unusual noises helps you detect any remaining air or early signs of hidden leaks.

A short drive also helps circulate the new fluid completely throughout the system, ensuring the pump, steering rack and hoses are working together smoothly.

When the steering feels quiet and responsive, it’s a clear indication that the bleeding process was successful and the system is ready for regular use.

Common Mistakes That You Should Avoid While Bleeding Power Steering Fluid

As well as, there’s a laboratory studies that shows that the type of hydraulic fluid matters for bleed, as fluids that release trapped air in the quick way that actually reduces pump losses and keep the steering quieter, also when you use a fluid with a good air-release properties that lowers the chance of persistent bubbles after bleeding and it improves overall steering efficiency.[¹]

1. Overfilling the Reservoir

Overfilling the power steering reservoir is a common mistake that can cause the fluid to foam, expand, or spill out when the system heats up during driving.

Power steering fluid expands when heated, so the reservoir is designed with a specific maximum level to allow the fluid room to expand safely.

When the reservoir is filled beyond this line, excess fluid can leak out through the cap or overflow vent, creating a mess and lowering the fluid level again.

The spilled fluid can also damage rubber parts, attract dirt, or create slippery surfaces around the engine bay.

Maintaining the correct fluid level is crucial because both too much and too little fluid can affect the pressure balance within the steering system.

Following the level markings ensures the system functions correctly and avoids unnecessary problems.

2. Turning the Wheel Too Quickly During Bleeding

Turning the steering wheel too quickly during the bleeding process can damage the power steering system by preventing air bubbles from properly rising and escaping.

Rapid movements can break larger air pockets into smaller bubbles, which take much longer to remove and can become trapped in hoses or the steering rack.

This can lead to steering noise, uneven pressure and the need to repeat the bleeding steps multiple times.

Turning the wheel slowly and deliberately allows the hydraulic fluid to gently push the air towards the reservoir without reintroducing air into the system.

Turning too quickly can also put excessive stress on the pump and steering components, specially when the vehicle is lifted or the engine is running.

Keeping movement stable and controlled during bleeding makes the process more effective and protects the system from damage.

3. Ignoring Leaks Before Bleeding

Ignoring leaks before starting the bleeding process is a critical mistake because any open point in the system can draw air back in, undoing all your work.

Power steering systems operate under high pressure and even a small leak in a hose, fitting, or pump seal can allow fluid to escape and air to enter simultaneously.

Bleeding a system with active leaks means that the air will not be completely removed and the steering may remain stiff, noisy, or unpredictable.

Leaks also reduce the fluid level, forcing the pump to work harder and increasing the risk of overheating or internal damage.

Checking for and repairing leaks beforehand ensures that the system can maintain proper hydraulic pressure and remain air-free after bleeding.

This step saves time, protects components and ensures long-term steering reliability.

4. Using the Wrong or Low-Quality Power Steering Fluid

Using the wrong type of power steering fluid or a low-quality fluid can lead to performance issues, chemical reactions with internal seals and accelerated wear on the pump or steering rack.

Different vehicles require different fluid formulations and using an unapproved type can result in improper lubrication, altered pressure behavior, or cause seals to swell or degrade over time.

Low-quality fluids may break down more quickly under heat, thicken, or form sludge that restricts flow within the system.

Hydraulic pumps rely on clean, stable fluid to generate pressure efficiently, so using the wrong fluid can lead to noise, stiffness, or premature pump failure.

Always using the fluid recommended by the manufacturer ensures proper compatibility, long-lasting performance and a successful bleeding process.

When You Should Consult With the Mechanic

1. Persistent Groaning Noise After Bleeding

If a groaning or whining noise persists from the steering system even after the bleeding process is properly completed, it indicates that air is still trapped or the power steering pump is beginning to fail internally.

This noise occurs because the pump struggles to move the fluid smoothly when air pockets or worn internal parts obstruct the flow.

A professional mechanic can use pressure gauges and diagnostic tools to measure the pump’s performance and pinpoint the exact cause of the noise, which is not feasible to do accurately at home.

2. Recurring Fluid Leaks

If you refill the system with fluid and clean up the old fluid, but the leak reappears, it signals a more significant problem such as a faulty hose, a cracked reservoir, loose clamps, or worn internal seals in the pump or steering rack.

These types of leaks typically require parts replacement or pressure testing.

A technician can use dye tests and inspection tools to accurately locate the source of the leak, ensuring the repair is done correctly and preventing future fluid leaks from the system.

3. Stiff Steering That Doesn’t Improve

When the steering wheel feels heavy or difficult to turn even after the bleeding process is complete, it could indicate a failing power steering pump, a clogged fluid passage, or an internal malfunction in the steering rack.

These issues affect hydraulic pressure, making it difficult to turn the wheel and resulting in uneven steering assistance.

A professional can measure the pressure output and inspect the condition of the rack and pump to determine the precise cause of the stiff steering.

4. Visible Damage to the Pump or Steering Rack

If you notice cracked housings, loose pulleys, damaged hoses, leaking seals, or corrosion on the power steering system components, it’s crucial to seek expert help immediately.

Physical damage often indicates that the internal parts are also worn or compromised and driving in this condition could lead to a sudden loss of steering assistance.

A professional mechanic can thoroughly inspect each component, determine which parts need replacing and safely repair the system.

Conclusion – How to Bleed Power Steering Fluid

Actually, when you do this bleeding process correctly then your power steering fluid gets properly functional and truly responsible as it restores the original strength, accuracy and reliability of your steering system.

When air becomes trapped inside the hydraulic lines, the power steering pump cannot maintain consistent pressure, leading to noise, stiffness and uneven steering response.

By removing this trapped air and replacing it with clean, bubble-free fluid, you help the system circulate properly, protect internal seals and reduce wear on the pump and steering rack.

A properly bled system not only makes steering lighter and more precise but also prevents long-term damage that can be costly to repair.

Whether you used the manual engine-off method or the engine-on method, the key indicators of success are quiet operation, a stable fluid level and a steering wheel that turns smoothly without any resistance.

If bleeding doesn’t resolve the issue, it usually indicates more serious problems such as leaks, pump wear, or internal rack damage, which require professional inspection.

Ultimately, learning to bleed the system gives you confidence, saves you money and helps extend the life of one of your car’s most crucial control components—your steering.

Now, it is time to ask questions in the comment section of this guide.

Frequently Asked Questions

Q1. What does power steering fluid bleeding mean?

Answer: Power steering fluid bleeding means removing trapped air from the power steering system. Air can enter the system due to leaks, low fluid levels, or after replacing parts like the pump or hoses. When air mixes with the fluid, it creates foam and reduces hydraulic pressure, leading to noisy, stiff, or jerky steering. Bleeding removes the air and allows the fluid to flow smoothly again, restoring proper steering performance.

Q2. Why is it necessary to bleed the power steering system?

Answer: It’s necessary because air in the system prevents the pump from maintaining consistent pressure. This can lead to pump failure, increased steering effort and noises such as whining or whistling. If air remains in the system for an extended period, it can cause overheating and damage the seals inside the steering rack. Bleeding the system ensures stable hydraulic pressure, proper steering function and extended lifespan of the components.

Q3. How do I know if my power steering system has air in it?

Answer: You can usually tell by the sound and feel of the steering wheel. If you hear whining, whistling, or grinding noises when turning the wheel, there may be air trapped in the fluid. Stiff, uneven, or sluggish steering response is another clear indicator. You might also see bubbles or foam inside the reservoir with the engine running. These symptoms occur because the air disrupts the fluid flow and forces the pump to work harder than necessary.

Q4. How long does power steering fluid bleeding take?

Answer: In most cases, proper bleeding takes approximately ten to twenty minutes. Manual bleeding with the engine off may take slightly longer because you are slowly turning the wheel by hand. Bleeding with the engine running is faster because the pump assists in removing the air automatically. The total time depends on how much air is trapped, the condition of the parts and whether the system has recently been repaired or completely drained.

Q5. Can I bleed the power steering system without starting the engine?

Answer: Yes, you can. This is called the manual or engine-off method. You fill the reservoir to the correct level and slowly turn the steering wheel several times from lock to lock. This movement pushes the air towards the reservoir without putting stress on the pump. Many technicians prefer to start with this method because it reduces the risk of the pump running dry and helps remove a significant amount of air before starting the engine.

Q6. What happens if I don’t bleed the power steering system after a repair?

Answer: If you don’t bleed the system, the steering may feel stiff, noisy and erratic. The pump may overheat because it won’t be able to build proper pressure and the fluid will foam as air passes through the system. Over time, this can lead to pump failure and wear on the internal parts of the steering rack. Failing to bleed the system after a repair, specially after replacing hoses or the pump, can shorten the lifespan of the entire system.

Q7. Can using the wrong power steering fluid cause problems?

Answer: Yes, using the wrong type of fluid can cause serious damage. Every car manufacturer specifies the correct fluid because each power steering system requires a specific viscosity and formulation to operate safely. Using the wrong fluid can cause seal swelling, low pressure, internal wear and noise. If you have mixed or used the wrong fluid, bleeding the system and refilling it with the correct type of fluid is one of the first steps to prevent further damage.

Q8. Why is my power steering still making noise after bleeding?

Answer: If the noise persists after bleeding the system, it may indicate that there is still air trapped in the lines or that the pump is failing. Sometimes, small air bubbles take longer to dissipate and may require another bleeding procedure. If the noise does not improve at all, it could indicate low fluid, leaks, cracked hoses, or damage inside the pump or steering rack. Persistent loud noise usually means the system needs to be checked by a professional.

Q9. Is it normal to see bubbles after bleeding?

Answer: Small bubbles may be visible during the bleeding process, but they should disappear once the system is fully bled. If bubbles continue to appear or if the fluid looks foamy, it means that air is still entering the system. This is usually caused by leaks, loose hose clamps, cracked seals, or low fluid levels. Persistent bubbles indicate a source of air entry into the system that needs to be fixed before attempting to bleed it again.

References:

[1] An Investigation of the Effects of Fluid Composition on Aeration, Efficiency and Sound Generation in an Axial Piston Pump

https://publications.rwth-aachen.de/record/724080/files/724080.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.