Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Even, there’s small issues like a loose shift knob can quietly affects the driving comfort and gear control as well; and if it is worn-out then it can affect shifting accuracy as well.

Basically, the gear shift knob is one of the most frequently used parts inside a car, as it has direct connection between the driver’s hand and the transmission system.

But, over the time, continuous use, vibration from the drivetrain, different kinds of harsh temperature changes inside the cabin and even the natural wear can cause the knob to loosen, fade up, loose grip or cracked up as well.

Plus, there’s automotive ergonomics research that shows that a secure and perfectly-installed shift knob actually improves shifting accuracy, even it reduces hand fatigue and helps the drivers to make the quicker and more confident gear changes as well, specially you’ll feel the positive impact in traffic or during the long drives as well.

So, this is the guide, which is specially focuses on How to Change a Gear Shift Knob, so that you can restore that proper control, protect the gear level from any kind of damage and also maintains the smooth transmission operation as well.

At First, We Should Understand About Gear Shift Knob Types and Their Mounting Styles

1. Manual vs Automatic Gear Shift Knobs

Manual and automatic gear shift knobs are designed differently due to their distinct functions.

A manual gear shift knob is primarily used to guide the gear lever through fixed gear positions and typically displays a gear pattern on its surface.

Its main purpose is to provide a firm grip and precise control during gear changes.

Automatic gear shift knobs often incorporate additional features such as release buttons, locking pins, or internal rods connected to the transmission’s safety system.

These features prevent accidental gear changes and require extra care during removal and installation.

It’s crucial to understand whether your vehicle has a manual or automatic transmission, as the replacement process and knob compatibility depend heavily on this.

2. Threaded Knobs – Screw-on Design

Threaded gear shift knobs are one of the most common designs, specially in manual vehicles.

These knobs screw directly onto the threaded end of the gear lever.

The thread size and direction can vary, meaning not all knobs are compatible with all vehicles.

A properly matched threaded knob provides a secure connection that prevents vibration and loosening during driving.

When installed correctly, the knob should sit straight, feel firm in the hand and maintain proper alignment of the gear pattern.

Overtightening should be avoided, as this can damage the threads on the gear lever and make future removal difficult.

3. Non-Threaded Knobs – Push-on or Clip-Based Design

Non-threaded gear shift knobs rely on pressure, clips, or internal retainers rather than screw threads.

These designs are often found in automatic vehicles and some modern manual cars.

The push-on knob is pressed firmly onto the gear lever and held in place by an internal locking clip or friction sleeve.

Some clip-based designs utilize retaining rings or pins that must be carefully removed before the knob can be detached.

These systems are designed to remain secure during normal driving, but their removal may require controlled force and the correct technique to avoid damaging internal components or the shift mechanism.

3. Locking Systems, Adapters and Set-Screw Mechanisms

Many aftermarket gear shift knobs utilize additional locking methods to fit a wider range of vehicles.

Set-screw mechanisms tighten against the gear lever using small screws, creating a secure grip without threads.

Adapters are often included to match different lever diameters or thread sizes, making a single knob compatible with multiple vehicles.

Locking systems help prevent the knob from rotating or becoming loose over time, specially with frequent gear changes.

Proper installation of these components is crucial, as uneven tightening or using the wrong adapter can lead to looseness, misalignment, or premature wear of the shift lever.

4. Considering Vehicle-Specific Compatibility

Not all gear shift knobs are universal and vehicle-specific design plays a critical role in proper fitment.

Factors such as thread size, lever length, transmission type and built-in safety features should be considered before choosing a replacement knob.

Some vehicles have shift boots, reverse lockouts, or electronic sensors integrated directly into the knob assembly.

Overlooking these details can result in poor fitment, obstructed gear movement, or malfunction of safety systems.

Checking the car’s manual or the manufacturer’s specifications ensures that the new gear shift knob will function correctly and maintain smooth, safe shifting performance.

How to Ensure Safety By Taking Precautions Before Starting

1. Parking the Vehicle on a Level Surface

Before attempting to replace the gear shift knob, the first and most crucial safety step is to park the vehicle on a level and stable surface.

A level surface prevents the vehicle from rolling or moving unexpectedly while you are working inside the cabin.

Even a slight incline can cause the vehicle to move if the gear lever is accidentally bumped while removing the knob.

A level surface keeps the transmission stable and ensures your body remains balanced, reducing the risk of slips or sudden movements that could damage the gear lever or internal components.

2. Engaging the Parking Brake Firmly

The parking brake is designed to hold the vehicle in place by locking the rear wheels and it should always be fully engaged before beginning this task.

Firmly engaging the parking brake adds an extra layer of safety, specially in manual transmission vehicles where the gear lever will be directly handled.

This prevents unintentional rolling if the gear position changes during the process.

A properly engaged parking brake also allows you to focus on your work without worrying about the vehicle moving.

3. Turning Off the Engine and Removing the Key

The engine should be completely turned off and the key removed from the ignition before working on the gear shift knob.

This step eliminates the risk of accidentally engaging a gear or activating electronic systems.

In modern vehicles, leaving the key in can activate electronic shift locks or sensors, which could hinder safe removal.

Removing the key ensures the transmission remains inactive and minimizes the potential for injury or damage.

4. Wearing Gloves for Better Grip and Injury Prevention

Wearing gloves provides a better grip and protects your skin during the removal and installation process.

Gear shift knobs can be tightly fitted and pulling or twisting them with bare hands can cause blisters, cuts, or strain injuries.

Gloves also help maintain a firm grip if the knob suddenly comes loose.

This simple step improves control and reduces the likelihood of slipping, specially when dealing with smooth or worn surfaces.

5. Avoid excessive force to protect the shift linkage

Applying excessive force when removing or installing the gear shift knob can damage the shift linkage or internal transmission components.

The gear lever is connected to sensitive mechanical or electronic parts that are not designed to withstand sudden or forceful pulling.

Applying steady and controlled pressure protects these components and ensures long-term reliability.

If resistance is felt, it indicates a locking mechanism or clip that needs to be released properly rather than forced.

Tools

| Tool or Material Name | What It Is Used For | Why It Is Important |

|---|---|---|

| Replacement Gear Shift Knob | New knob to replace old or worn knob. | This ensures proper grip, comfort and complete control over the gear. |

| Screwdrivers – Flathead or Phillips | It is used to remove screws, clips, or trim around the gear shift knob. | Helps reach hidden fasteners without damaging internal parts. |

| Allen Keys or Hex Wrenches | It is used to loosen or tighten the set screws on some gear shift knobs. | Allows for secure installation without the need for over-tightening. |

| Adjustable Wrench or Pliers | Helps loosen tightened knobs or hold adapters during fitting. | It provides extra grip when hand strength is not enough. |

| Protective Cloth or Rag | Placed between tools and surfaces. | Prevents damage to gear lever and interior trim. |

| Thread Adapters | Installs new knobs for different thread sizes. | Ensures secure and precise fitting on the gear lever. |

How to Remove the Old Gear Shift Knob

1. Identifying the Knob Attachment Method

Before applying any force, it’s important to understand how the gear shift knob is attached to the gear lever.

Different vehicles have different attachment systems, such as a threaded design, internal clip, retaining ring, or locking button.

A close look at the base of the knob and where it meets the shift boot will reveal whether it’s screwed on, pulled off, or requires a mechanism for removal.

Correct identification can prevent unnecessary force and reduce the risk of damaging the shift lever or surrounding trim.

2. Properly Unscrewing a Threaded Shift Knob

Threaded gear shift knobs are designed to be removed by turning them in the opposite direction of tightening, usually anti-clockwise.

Firm but gentle turning with both hands is often enough to loosen the knob.

If you feel any resistance, apply slow and controlled pressure instead of sudden force.

In some cases, the knob may appear stuck due to dirt, old thread sealant, or prolonged use, but patience and consistent turning will loosen the threads on the gear lever and allow for safe removal.

3. Removing the Clip or Retaining Ring on a Non-Threaded Knob

Non-threaded gear shift knobs are held in place by internal clips or retaining rings that lock the knob to the lever.

These designs are common in automatic vehicles and newer models.

To remove them safely, the retaining mechanism must be removed before pulling up on the knob.

Pulling without removing the clips may break the clips or damage the internal locking mechanism.

Slow but controlled movements ensure that the knob disengages easily without damaging the shift assembly.

4. Handling an Automatic Transmission Knob with a Release Button

Automatic transmission knobs often have a built-in release button connected to a rod or locking pin inside the knob.

This button controls gear movement and is part of the vehicle’s safety system.

When removing such a knob, great care must be taken to avoid damaging the button mechanism or internal rod.

The knob should only be lifted once any locking parts are detached and the button should be supported so that it does not become loose.

Proper handling ensures that the transmission continues to operate safely after reinstallation.

5. Inspecting the Open Shift Lever After Removal

After removing the old gear shift knob, carefully inspect the open shift lever before installing the new knob.

The threads, clips, or smooth surfaces should be clean and free of damage.

Dirt, rust, or worn threads can affect how securely the new knob will fit.

Checking the lever at this stage helps prevent movement, misalignment, or looseness after installation and ensures that the new gear shift knob will fit correctly and function as intended.

What to Check In New Gear Shift Knob Before Changing It

1. Checking for Correct Thread Size or Adapter Fit

Before installing a new gear shift knob, it’s crucial to ensure that the thread size or fitting perfectly matches the gear lever.

Gear levers come in various diameters and thread types and even a slight mismatch can result in a loose fit or improper tightening.

Carefully checking the fit by hand ensures that the knob or adapter screws on smoothly without resistance.

A proper fit creates a secure connection, preventing wobbling during driving and protecting the threads from damage caused by forced installation.

2. Aligning the Shift Pattern and Orientation

Many gear shift knobs feature a shift pattern or a specific forward-facing design that needs to be correctly aligned.

Proper orientation ensures that the gear numbers are easily readable and that the knob feels natural in the driver’s hand.

Incorrect alignment can lead to confusion when selecting gears and reduce driving comfort.

Before fully tightening the knob, it should be adjusted so that the pattern faces straight forward when the transmission is in neutral or park, facilitating clear and consistent gear changes.

3. Installing Adapters or Inserts – If It is Necessary

Some gear shift knobs include adapters or inserts for different vehicles.

These parts help accommodate variations in thread size or lever shape and must be properly installed for a secure fit.

The adapter should sit firmly on the gear lever without any gaps or looseness.

Correct installation of the adapter ensures that the knob remains stable during repeated gear changes and minimizes long-term wear on both the knob and the gear lever.

4. Checking the Internal Locking or Tightening Mechanism

Many modern gear shift knobs utilize an internal locking system or tightening mechanism, such as a set screw or pressure lock.

These components secure the knob in place and prevent it from rotating or becoming loose over time.

Before installation, these mechanisms should be inspected to ensure they operate smoothly and tighten evenly.

Proper inspection at this stage helps prevent future problems such as rattling, misalignment, or sudden loosening while driving, ensuring safe and reliable performance.

How to Install a New Gear Shift Knob

1. Securely Tightening a Threaded Knob Without Overtightening

When installing a threaded gear shift knob, it should be screwed onto the gear lever gently and evenly by hand.

The knob should tighten smoothly without resistance, indicating that the threads are properly aligned.

Hand-tightening is usually sufficient for a firm and secure fit.

Overtightening can damage the threads on the gear lever or inside the knob, making future removal difficult.

A properly tightened knob feels solid but still allows the shift pattern to remain correctly aligned.

2. Properly Press-Fitting a Non-Threaded Knob

Non-threaded gear shift knobs are designed to be securely press-fitted using internal clips or a pressure lock.

These knobs should be pressed straight onto the gear lever with firm and controlled force.

Tilting the knob during installation can weaken the locking mechanism or result in uneven seating.

When properly installed, the knob should sit flush with the shift boot and feel secure without any looseness during shifting.

3. Evenly Tightening Set Screws

Some gear shift knobs utilize set screws to hold the knob in place.

These screws should be tightened evenly to center the knob on the gear lever.

Uneven tightening can cause the knob to sit crooked or feel unstable during use.

Tightening gradually and in a balanced manner distributes the pressure evenly, resulting in better stability and preventing loosening over time due to vibrations and repeated gear changes.

4. Reinstalling Any Trim or Shift Boot Components

After installing the new gear shift knob, any removed trim pieces or the shift boot should be carefully reinstalled.

These components protect the gear mechanism from dust and dirt and give the interior a clean, finished look.

Reinstalling them correctly ensures that the shift boot moves freely during gear changes and does not bind or restrict the movement of the knob.

5. Ensuring Proper Alignment and Stability

The final step is to verify that the gear shift knob is properly aligned and feels stable in all gear positions.

The knob should not rotate, wobble, or lift during normal shifting.

Checking the alignment while shifting through all the gears ensures smooth operation and confirms that the installation was successful.

Proper stability enhances driving confidence and helps maintain the long-term reliability of the shifting system.

How to Test the New Gear Shift Knob After Installation

1. Checking Knob Tightness and Movement

After installing the new gear shift knob, the first test is to gently wiggle and rotate the knob by hand.

A properly installed knob should feel solid and remain firmly attached to the gear lever without rotating or lifting.

Any looseness can compromise control and may worsen over time due to vibrations during driving.

This simple check helps ensure the knob is securely fastened and safe for regular use.

2. Shifting Through All Gears While Stationary

Before driving, with the vehicle stationary, the gear lever should be moved through all available gears.

This test verifies that the knob allows for full and smooth movement without any obstructions.

Shifting while stationary helps identify any alignment issues or fitting problems, ensuring that each gear position engages correctly.

This step also minimizes the risk of unexpected behavior during driving.

3. Confirming Proper Engagement and Smooth Operation

Proper engagement means that each gear selection feels distinct and precise.

The gear shift knob should move smoothly without sticking, grinding, or unusual resistance.

Smooth operation indicates that the knob is correctly fitted and is not interfering with the gear lever or internal mechanisms.

Any rough or vague shifting may indicate improper installation and should be addressed before driving.

4. Verifying Clearance from Surrounding Trim or Console

The final test is to check that the gear shift knob does not touch or rub against the center console, trim panels, or shift boot during operation.

Sufficient clearance ensures longevity and prevents noise, wear, or damage to surrounding interior components.

Verifying the clearance ensures that the knob is in the correct position and allows for smooth gear changes in all driving conditions without any obstruction.

Common Mistakes That You Should Avoid While Changing of Gear Shift Knob

Now, there’s study on how different gearshift operation methods such as: lever slide, button push and dial rotation and their placement inside the vehicle affects the drivers comfort, safety and usability. So, with the 40 participants with the varieties of driving experience they have rated 15 design combinations across the 9 ergonomic measures such as: accuracy, intuitiveness and satisfaction. Basically, researchers have found out that the lever slide and button push operation methods in center console and lower fascia locations actually scored highest, that’s why it suggest that how a gearshift is designed and where it is actually positioned directly influences that how easily and safely you can use it.[¹]

1. Using the Wrong Thread Size or Adapter

One of the most common mistakes when replacing a gear shift knob is using the wrong thread size or adapter.

Gear levers are manufactured with specific thread patterns and a mismatch can result in the knob becoming loose or not tightening properly.

Forcing an incorrect size can strip the threads on the gear lever, leading to costly repairs.

Always ensuring the correct fit guarantees a secure connection and long-lasting reliability.

2. Overtightening and Damaging Threads

Overtightening the gear shift knob is a common problem that can damage the threads on both the knob and the gear lever.

Excessive force can cause the knob to crack internally or flatten the threads, making it difficult to remove in the future.

A properly installed knob should be firm and stable without requiring excessive force.

Hand-tightening is usually sufficient to secure the knob and protect the threaded connection.

3. Misaligning the Shift Pattern

Misalignment of the shift pattern is another common mistake that leads to usability issues.

When the gear numbers or markings are not facing forward, it can confuse the driver and reduce shifting accuracy.

Correct alignment ensures that each gear position is easy to identify and select.

Taking the time to adjust the orientation before final tightening improves comfort and driving confidence.

4. Forcing Removal or Installation

Applying excessive force during removal or installation can damage internal clips, locking pins, or the shift linkage itself.

Gear shift mechanisms are designed to be robust but precise and sudden pulling or twisting can cause hidden damage.

If resistance is faced, it indicates that the locking system or clips need to be properly released.

Careful and controlled handling protects both the transmission and the interior components.

5. Ignoring Manufacturer’s Specific Instructions

Each vehicle and gear shift knob may have unique design features that require specific installation steps.

Ignoring the manufacturer’s instructions can lead to improper fitment, safety issues, or damage to built-in locking systems.

The vehicle manual and product guide contain crucial information regarding thread sizes, locking mechanisms and installation limitations.

Following these instructions ensures proper function, safety and long-lasting performance.

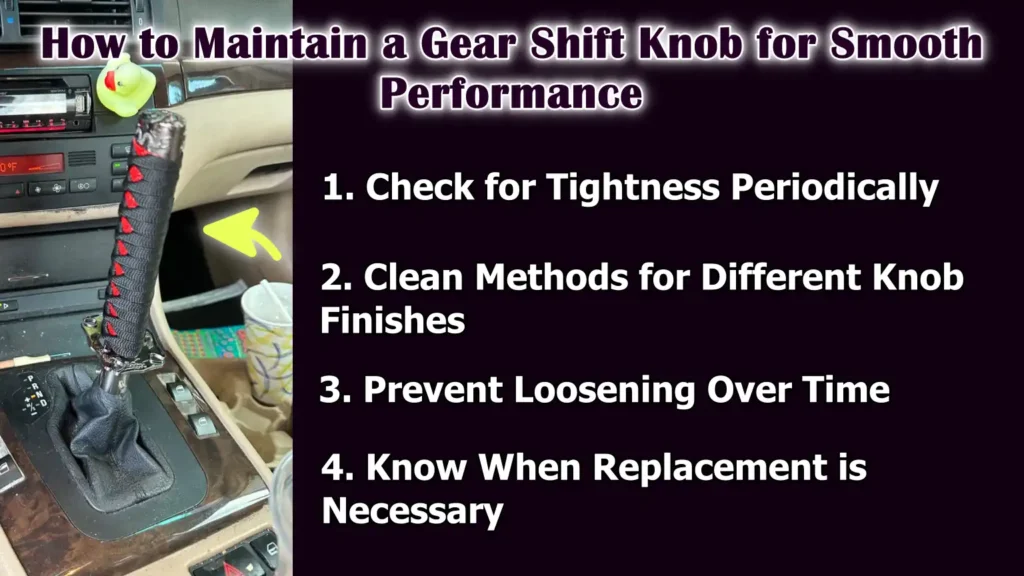

How to Maintain a Gear Shift Knob for Smooth Performance

1. Check for Tightness Periodically

Gear shift knobs are constantly exposed to movement, vibration and hand pressure, which can cause them to gradually loosen over time.

Regularly checking for tightness ensures that the knob remains securely attached to the gear lever.

A loose knob can compromise control and make gear shifting feel imprecise or unsafe.

A simple check by hand every few weeks or during regular vehicle inspections can detect looseness early and prevent further wear or damage.

2. Clean Methods for Different Knob Finishes

Keeping the gear shift knob clean improves both its appearance and grip.

Dirt, sweat and hand oils can accumulate over time and make the surface slippery.

Using a soft cloth with a mild cleaning solution is usually sufficient to remove dirt without damaging the finish.

Harsh chemicals or abrasive materials should be avoided as they can damage the surface and shorten the knob’s lifespan.

Regular cleaning also helps maintain a comfortable and hygienic driving environment.

3. Prevent Loosening Over Time

Preventing loosening starts with proper installation, but consistent maintenance is equally important.

Driving vibrations and frequent gear changes can gradually loosen the knob’s attachment.

Ensuring that threads, adapters, or locking mechanisms are properly engaged helps maintain a secure grip.

Addressing any slight looseness promptly prevents further wear on the gear lever and keeps the knob stable during everyday driving.

4. Know When Replacement is Necessary

Even with proper care, gear shift knobs wear out over time due to constant use and exposure to heat and vibrations.

Signs such as cracks, fading color, rough texture, or persistent looseness indicate that a replacement may be necessary.

A worn-out knob can reduce grip and make shifting gears uncomfortable or less precise.

Replacing the knob at the right time helps maintain smooth operation and ensures a safe and comfortable driving experience.

Read More:

When You Should Consult to the Vehicle Professional

1. Vehicles with Complex Electronic Shift Systems

Some modern vehicles have electronic shift systems where the gear shift knob is connected to sensors, wiring, or computer-controlled components.

These systems rely on precise signals to ensure safe gear selection and prevent unintended movement.

Attempting to remove or replace the knob without the correct knowledge can trigger warning lights or damage the shifter mechanism.

Seeking professional help ensures that the electronic connections remain intact and the system continues to function safely.

2. Integrated Locking or Safety Mechanisms

Many vehicles have built-in locking or safety mechanisms within the gear shift knob, such as a shift lock button or internal rods.

These parts are designed to prevent accidental gear changes and are often linked to the transmission’s safety features.

Improper handling can damage these mechanisms.

A professional technician knows how to properly release and reinstall these systems, maintaining both safety and functionality.

3. Difficulty Removing Factory-Installed Knobs

Factory-installed gear shift knobs are often very tightly fitted and may have hidden clips or locking components.

If the knob doesn’t loosen with normal effort, forcing it can damage the shift lever or surrounding trim.

Persistent difficulty indicates that a specific removal procedure is required.

Professional assistance can prevent broken parts and unnecessary repairs.

4. Concerns About Damaging the Transmission

If there are any concerns about damaging the transmission or shift linkage, professional help is the safest option.

The gear lever is directly connected to critical mechanical or electronic components that control gear engagement.

Damage to this area can lead to shifting problems or safety hazards.

A trained professional can assess the situation and complete the replacement without risking long-term problems with the transmission.

Conclusion – How to Change a Gear Shift Knob

Now, it is clear that by just having a few careful steps during installation you can literally improve driving feel, reduce the hand fatigue and that keeps the gear changes clear and really predictable.

The gear shift knob is the primary point of interaction between the driver and the transmission and even minor issues like looseness, misalignment, or worn surfaces can compromise shifting accuracy and driver confidence.

And, by understanding the correct knob type, attachment method and installation process, vehicle owners can avoid common mistakes that can lead to damaged threads, unstable fittings, or safety concerns.

As well as, with the proper preparation, careful installation and thorough testing ensure that the new knob operates smoothly with the gear lever and does not interfere with surrounding trim or internal mechanisms.

So, that’s all from this guide, now let us know if there’s any unsolved queries that bothers you regarding this guide.

Frequently Asked Questions

Q1. What does a gear shift knob do in a car?

Answer: The gear shift knob is the part of the gear lever that the driver grips to change gears. It helps guide the gear lever smoothly and securely into the correct position. A good gear shift knob provides proper grip, comfort and control, making gear changes easy and precise. Because it’s used multiple times during every drive, its condition directly impacts how the car feels when shifting gears.

Q2. Is it safe to replace a gear shift knob at home?

Answer: Yes, replacing a gear shift knob at home is generally safe if the vehicle has a simple manual or standard automatic transmission. The process doesn’t involve opening the transmission or working with fluids. However, caution should be exercised to identify the correct attachment type and avoid forcing anything. Vehicles with electronic or complex locking systems may require professional assistance.

Q3. How do I know if my gear shift knob unscrews or pulls off?

Answer: The attachment method depends on the vehicle’s design. Many manual cars have threaded knobs that unscrew by turning them anti-clockwise. Some automatic and modern vehicles have push-on knobs with clips or internal locks. Checking the base of the knob, consulting the owner’s manual, or gently testing for movement will help identify how it’s attached before attempting to remove it.

Q4. Can the wrong gear shift knob damage my car?

Answer: Yes, using the wrong gear shift knob can cause problems. Incorrect thread size or poor fitment can strip the gear lever threads, lead to looseness, or interfere with proper gear engagement. In automatic cars, the wrong knob can affect the shift lock system. Always ensure the knob is compatible with your vehicle before installation.

Q5. Why does my gear shift knob feel loose after installation?

Answer: A loose gear shift knob usually means it wasn’t tightened correctly or the wrong adapter was used. Vibrations from driving can also cause slight loosening over time. If the knob uses set screws, uneven tightening can lead to instability. Properly tightening and checking the fitting usually resolves the issue.

Q6. Should I use tools to tighten the gear shift knob?

Answer: Most threaded gear shift knobs should only be tightened by hand. Using tools can apply excessive force and damage the threads. Tools should only be used when working with set screws or adapters and even then, tightening should be done slowly and with control to avoid damage.

Q7. Can I replace the gear shift knob in an automatic car?

Answer: Yes, but automatic cars often have more complex knob designs. Many automatic shift knobs have internal rods connected to release buttons or safety systems. These parts should be handled carefully during removal and installation. If the knob doesn’t come off easily or contains electronic components, professional assistance is recommended.

Q8. What should I check after installing a new gear shift knob?

Answer: After installation, the knob should feel secure and have no play. All gears should shift smoothly when the vehicle is stationary. While driving, the knob should not touch the center console, trim, or shift boot. These checks confirm proper installation and safe operation.

Q9. How often should a gear shift knob be replaced?

Answer: There is no fixed time to replace a gear shift knob. It should be replaced when it becomes loose, broken, slippery, uncomfortable, or worn out. Signs such as fading color, peeling, or difficulty gripping indicate that it’s time for a new knob. Replacing it improves comfort and control.

Q10. Can a loose gear shift knob affect driving safety?

Answer: Yes, a loose gear shift knob can reduce control and make gear changes vague or slow. In some cases, it might even come off while driving, leading to a sudden loss of control during shifting. Keeping the knob tight and secure helps maintain safe and predictable gear operation.

Q11. Is it necessary to align the shift pattern on the knob?

Answer: Yes, alignment is important, specially in manual cars. If the shift pattern is not facing forward, it can confuse the driver and slow down the gear shifting process. Correct alignment improves ease of use and ensures proper hand positioning while driving.

References:

[1] An Ergonomic Study on the Operation Method and In-Vehicle Location of an Automotive Electronic Gearshift

https://www.mdpi.com/2076-3417/14/2/672

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.