Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

It is the clear fact that a worn wheel bearing can actually make your car louder, rougher and even it gets you to have less fuel-efficient vehicle as well.

Without a second thought, wheel bearings are truly powerful components that works to smoothens the movement of your car.

Plus, each of the wheel has a bearing assembly that literally allows it to rotate with really minimal friction while it supports the vehicle’s weight as well: which is considered several hundreds of kilograms per wheel.

But over the period of time and usage, it gets constant pressure, heat, dirt and water that can literally cause these bearings to wear out or lose the proper lubrication, so that leads to a distinctive humming, grinding or rumbling noise that many drivers actually mistake for tire or brake problems but it can be the bearings that causes that as well.

Not only this, according to automotive service data, even a faulty wheel bearing can increase friction by more than 30%: which is literally affects ride comfort and also reduces fuel efficiency and even it puts extra strain on suspension and braking systems as well.

If you doesn’t care for them in the correct time, then a damaged bearing can overheat, seize and even it can cause the wheel to detach in severe cases: that actually tells the how important it is to diagnose the wheel bearings for safety purpose.

You should not thing that you just fixing a sound by checking a wheel bearing noise, as it is more about preventing potential wheel failure, it improves handling precision and literally maintain overall vehicle’s stability as well.

Which is why this guide is to show you How to Check Wheel Bearing Noise, so that you can identify early warning signs and maintain your vehicle’s safety and comfort quiet easily.

First, We Have to Understand About Wheel Bearing Noise

Wheel bearing noise is one of the most common yet misunderstood sounds drivers hear as their vehicle ages.

When a wheel bearing begins to wear out or loses lubrication, it produces a distinctive sound that varies depending on the wheel’s speed, direction and pressure.

As the bearing’s primary function is to ensure smooth rotation of the wheel hub with minimal friction, any damage to its metal surfaces or seals can cause metal-to-metal contact.

This friction produces sound vibrations that travel through the car’s suspension and body, making them easy to hear but sometimes difficult to detect.

Understanding the nature of these sounds can help drivers distinguish between worn bearings and other mechanical problems.

1. Types of Wheel Bearing Noise

The most commonly recognized sounds from bad wheel bearings are grinding, humming, rumbling, or rattling sounds.

A grinding noise often means that the bearing’s internal grease has leaked and the metal balls or rollers are rubbing directly against each other.

In the early stages of wear, when the bearing surface begins to become rough or uneven, a humming sound is usually heard.

This rumble is often deep and its intensity varies with vehicle speed, becoming more noticeable when cornering or when the load shifts from one side to another.

In most cases, these sounds become louder as the vehicle speed increases or when more stress is placed on the bearing.

2. How Wheel Bearing Sounds Differ from Other Vehicle Sounds

Many drivers confuse wheel bearing sounds with tire noise, brake noise, or CV joint problems because they often sound similar.

Tire noises have a consistent pattern or rhythmic tone that doesn’t change much when cornering and this often depends on the tire tread design or uneven wear.

Brake noise, on the other hand, is heard only when braking—usually a squealing or rattling sound caused by worn brake pads or corrosion on the rotor surface.

CV joint problems typically cause clicking or popping sounds, specially during sharp turns or acceleration.

However, wheel bearing noise changes significantly when the vehicle is turning or the load shifts.

For example, if you turn left and the noise increases, it often means the right-side bearing is worn and vice versa.

3. Speed, Steering and Load Affect Wheel Bearing Noise

The intensity of wheel bearing noise is directly related to how fast the wheel rotates and how much load or force is applied.

As vehicle speed increases, the bearings rotate faster, increasing friction noise.

At low speeds, the noise may be soft, but at highway speeds, it often turns into a distinctive buzzing or rumble.

The direction of steering also changes the pressure on each wheel bearing.

When the vehicle turns, the outer bearings bear more load, which can accelerate wear.

Similarly, carrying extra weight or unevenly distributed loads increases the pressure on the bearings, causing more noticeable noise.

Understanding these changes helps identify which bearings are worn and ensures a more accurate diagnosis.

Wheel bearing noise may initially seem like a minor annoyance, but it’s actually an early warning sign of a mechanical problem that could affect your car’s safety and performance.

Recognizing these distinctive sound patterns—as well as knowing how speed and steering affect them—helps you take timely action before the problem escalates into more serious damage or costly repairs.

Tools

| Tool Name | Purpose / Use | Description in Easy Words |

|---|---|---|

| Jack | To lift the car off the ground. | A sturdy metal device used to safely lift a car so you can inspect or rotate the wheels. |

| Jack Stands | To keep the car safely upright after lifting. | Solid bases that keep the car stable even after jacking it up. |

| Wheel Chocks | To prevent the car from rolling. | Small wedge-shaped blocks placed behind or in front of the tires to keep the vehicle moving. |

| Mechanic’s Stethoscope or Screwdriver | Listen for wheel bearing noise. | A device that allows you to hear or feel vibrations inside the hub. A simple screwdriver can also be used, with the tip on the hub and the handle near your ear. |

| Torque Wrench | To tighten nuts and bolts correctly. | A wrench that measures how tight a nut or bolt is, to prevent it from being over- or under-tightened. |

| Safety Gloves | To protect your hands. | Thick gloves that protect your hands from sharp edges, grease and heat. |

| Safety Goggles | To protect your eyes. | Transparent glasses that prevent dust, rust or metal particles from getting into your eyes while you work. |

| Chassis Ear (Electronic Listening Device) | To detect noise while driving. | A set of clip-on microphones and a control box that help pinpoint where noise is coming from, even while the car is running. |

| OBD-II Scanner | To check sensor-related alerts. | A small electronic device that connects to the car’s diagnostic port to read any error codes, specially if your vehicle is equipped with a wheel speed sensor. |

Basic Safety Precautions Before Testing The Wheel Bearing Noises

Before checking for wheel bearing noise, it’s important to take safety seriously.

Working around a vehicle that’s elevated above the ground can be dangerous if proper precautions aren’t followed.

Taking some time to prepare the workspace and take the right safety measures can prevent serious injuries or damage.

Every small action—like parking correctly or wearing protective equipment—makes a big difference in keeping the process safe and smooth.

1. Parking the Vehicle on a Level Surface

Always park your car on a completely level and solid surface before any inspection.

A level surface ensures the vehicle remains stable when lifted, which is crucial when using a jack or jack stands.

Avoid working on slopes, gravel, or soft ground, as the jack may slip or sink, causing the car to fall.

If possible, use a garage floor or concrete driveway, as these provide a firm and level base.

A flat surface also makes it easier to position the wheel chocks and keeps your tools within easy reach without the risk of rolling or slipping.

2. Engaging the Parking Brake and Using Wheel Chocks

After parking the car, firmly apply the parking brake to prevent it from rolling.

However, remember that the parking brake typically only locks the rear wheels, so wheel chocks are necessary as an additional safety measure.

Wheel chocks are small wedges tightly applied to the tires that hold them in place, preventing them from moving even when the other wheel is raised.

This combination of the parking brake and chocks creates a secure base, allowing you to concentrate on your inspection without worrying about the car suddenly moving or rolling.

3. Wearing Safety Equipment

Safety equipment is often overlooked, but it protects you from many minor hazards when working on a vehicle.

Always wear safety gloves to protect your hands from sharp metal edges, dirt and grease.

Gloves with rubber or textured grips can also prevent tools from slipping.

Additionally, wear safety glasses to protect your eyes from falling dust, rust particles, or small debris when rotating or inspecting the wheels.

If you’re working in a poorly ventilated area, ensure there’s good lighting and ventilation, or use a small fan to maintain airflow.

Wearing the right clothing helps you stay comfortable, focused and safe while inspecting your vehicle.

4. Never work under a vehicle that’s jacked up

One of the most important safety rules when inspecting wheel bearings or any undercarriage component is to never rely solely on the jack to support the vehicle’s weight.

A jack is designed for lifting, not for prolonged support.

Even the slightest movement can cause it to lose pressure, slip, or move.

After raising the vehicle, always place sturdy jack stands under the correct lift points and slowly lower the vehicle onto them.

This ensures that the vehicle remains in place even if the jack fails.

Checking for wheel bearing noise often involves rotating or shaking the wheels and without proper support, this movement can cause the vehicle to suddenly roll over.

This extra step of using jack stands can literally mean the difference between a safe inspection and a serious accident.

How to Check Wheel Bearing Noise – Perfect Guide

How to Do Road Test

A road test is the first and most important step in identifying worn or noisy wheel bearings.

It helps you understand how the car sounds when driving at different speeds and steering conditions.

This test requires no equipment—only attention, patience and a safe driving location.

By observing changes in noise, you can determine which wheel bearing is failing before any physical inspection.

1. Driving at Different Speeds to Detect Sounds Like Buzzing or Squeaking

Begin your test by driving on a quiet, smooth road where you can safely vary your speed.

Start slowly and gradually increase speed.

Pay close attention to sounds coming from around the wheels.

A buzzing sound that increases with speed usually indicates early bearing wear.

If this sound changes to a grinding or rattling sound at high speeds, it means the inner surface of the bearing is rough and possibly losing lubrication.

Bearings rotate thousands of times per minute while driving, so even minor damage produces a repetitive sound pattern that intensifies as the car speeds up.

If you find that the sound diminishes when you slow down or stops completely when you stop, this confirms that the problem is with a moving part like the bearings, rather than something static like the brakes.

Observing the sound change with speed gives you the first big clue whether your bearings are wearing out.

2. Look for changes in the sound when turning the steering wheel left or right

After testing at straight speeds, it’s time to observe how the sound responds to steering.

Wheel bearings handle side loads differently depending on the direction of the turn.

When you turn the steering wheel left, the car’s weight shifts to the right; When you turn right, it shifts to the left.

A worn bearing on the loaded side makes a louder noise because it can’t handle the extra pressure.

For example, if the humming or rattling sound increases when turning left, the right-side bearing is worn out.

If the noise gets louder when turning right, the left-side bearing may be bad.

This happens because the small metal balls or rollers inside the damaged bearing move unevenly under the extra load.

Rough surfaces wear more, causing the rattling or popping sound.

Listening carefully at every turn helps identify the part of the vehicle where the problem is.

3. Look at the side where the noise is getting louder

After checking the speed and steering, focus on locating the source of the noise.

Wheel bearing noise can sometimes resonate throughout the car’s body, so paying attention to the pitch, direction and timing can help you locate the faulty part.

If the noise gets louder when turning in one direction and lessens when turning in the other, it almost always means the problem is on the other side of the turn.

Try testing on both smooth and slightly rough roads, as this can confirm your observation.

If the noise remains consistent on all types of roads and varies significantly with steering, it’s a sure sign that the bearings, not the tires or brakes, are the root cause.

Writing down your findings after the road test will make the next inspection steps faster, more accurate and safer.

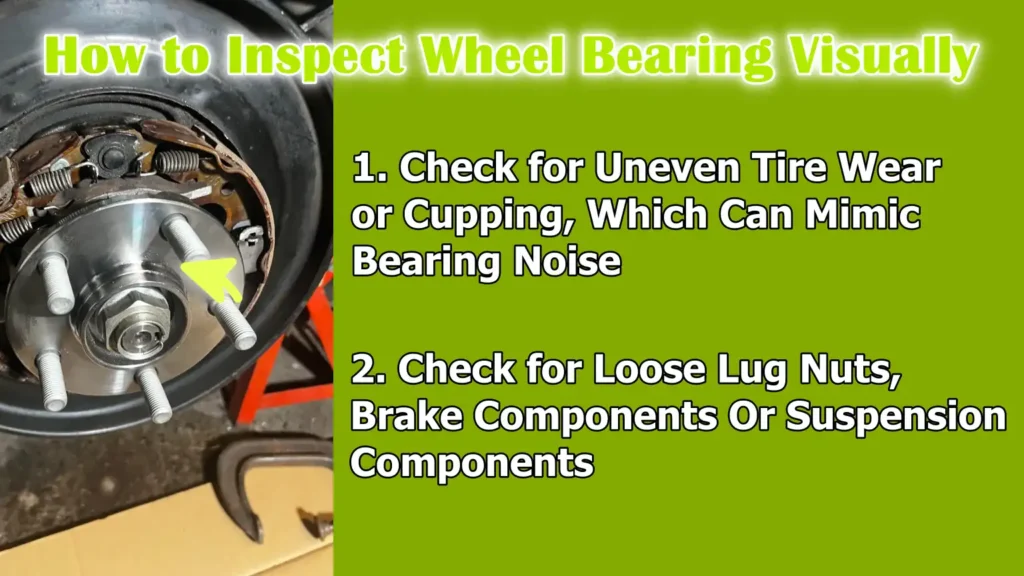

How to Inspect Wheel Bearing Visually

After completing the road test, the next step in checking for wheel bearing noise is a careful visual inspection.

This step allows you to confirm whether the noise you hear is actually coming from the wheel bearing or from another nearby component, such as the tire, brakes, or suspension.

Many cars can have similar noises, so a careful inspection of the area around the wheel often provides clues that can confirm or deny a bearing problem.

A few minutes spent inspecting these areas in good lighting can save you from unnecessary repairs and help you better understand the overall condition of your vehicle.

1. Check for Uneven Tire Wear or Cupping, Which Can Mimic Bearing Noise

One of the most common causes of sounds resembling bad wheel bearings is uneven tire wear, specifically a pattern called cupping or scalloping.

This occurs when the tire tread wears unevenly, creating small pits or raised spots on the tire surface.

As the wheel rotates, these raised and lower parts hit the road unevenly, creating a rhythmic humming or rumbling sound that can be reminiscent of a bad bearing.

The easiest way to check this is to gently stroke the tire surface.

If it feels rough or has small wavy patterns, the tire may be the source of the noise.

Wheel misalignment, unbalanced tires, or worn suspension components can cause cupping, so it’s important to identify it early.

Also, look for feathering, bald spots, or one side of the tire wearing faster than the other.

These are clear signs that the tires aren’t making even contact with the road surface, which can cause noise at specific speeds.

By checking your tires first, you can eliminate one of the most common false signs of a wheel bearing problem.

If your tires are evenly worn but still make noises that vary with speed or direction, the root cause is most likely the wheel bearings.

2. Check for Loose Lug Nuts, Brake Components Or Suspension Components

The next part of the visual inspection involves checking the hardware surrounding the wheel for loose or damaged components.

First, inspect the lug nuts that hold the wheel in place.

Loose lug nuts can cause clicking or rattling sounds and vibrations, which may resemble worn bearings.

Make sure all nuts are properly tightened using a torque wrench according to your vehicle manufacturer’s instructions.

After checking the lug nuts, pay attention to the brake components.

Loose brake caliper brackets or worn brake pads can cause a scratching or grinding noise that changes when you press or release the brake pedal.

To inspect the brake rotor surface and caliper mountings, carefully examine the wheel spokes, or remove the wheel if necessary.

The rotor should be smooth and free of deep grooves or rust that could rub against the pads.

Finally, check the surrounding suspension components, such as the control arms, ball joints and sway bar links.

Any looseness or slack in these components can cause noise while driving, specially on rough roads or around turns.

Suspension noises often mimic wheel bearing noise, which can confuse even experienced drivers.

Using a flashlight, check for worn rubber bushings, broken joints, or fluid leaks from struts and shock absorbers.

If these components appear strong and secure, but you still hear noise when the wheel rotates, the wheel bearings are most likely the cause.

How to Inspect the Wheel Physically

After completing the road test and visual inspection, the next step in diagnosing wheel bearing noise is to physically inspect the wheel.

This step allows you to detect any looseness or roughness that may not be visible.

Worn wheel bearings often produce subtle movements or vibrations that can be felt through the wheel hub and early detection can prevent serious damage such as wheel separation or uneven tire wear.

Performing a physical inspection requires proper safety measures and careful handling to ensure an accurate diagnosis without risking injury.

1. Safely Raising the Car Using a Jack and Stands

Before touching the wheel, the vehicle must be safely raised.

Start by placing a jack under the car manufacturer’s recommended lift point.

Slowly raise the vehicle until the wheel is off the ground.

After raising, it is important to place jack stands under the car, as relying solely on the jack is unsafe.

Jack stands provide a stable and secure support, preventing the vehicle from falling during inspection.

Ensure the surface is level and solid and always use wheel chocks on tires resting on the ground to prevent any movement.

Proper lifting ensures safety and also allows for accurate diagnosis of bearing problems.

2. Hold the tire at the 12 and 6 o’clock positions and rock it back and forth

After raising the wheel, the next step is to check for play in the wheel hub.

Place your hands on the upper (12 o’clock) and lower (6 o’clock) positions of the tire.

Rock the wheel slowly back and forth toward and away from the car.

A healthy bearing will feel solid and smooth with minimal movement.

Any noticeable looseness, clicking, or grinding indicates that the bearing may be worn or that there is play in related suspension or hub components.

This method allows you to detect axial movement, which is a common early sign of bearing failure.

3. Looseness or Roughness – Signs of a Worn Bearing

When rocking the wheel, pay attention to both the speed and texture.

Worn bearings often cause a rough or sandy feel when the wheel rotates or moves.

This is caused by uneven or damaged rolling elements within the bearing, which can increase friction and vibration.

Axial looseness, which is actually side-to-side looseness, is a key sign that the bearing is no longer firmly gripping the wheel hub.

Detecting these signs early helps prevent further damage to the hub assembly, suspension and tires and also ensures that the car remains safe to drive.

Feeling the difference between smooth and rough rotation is one of the most reliable ways to diagnose wheel bearing problems.

How to Rotate the Wheel by Hand

After physically inspecting the wheel, the next step in diagnosing wheel bearing noise is to rotate the wheel by hand.

This step can help you detect subtle roughness, wear, or unusual resistance that may not be noticeable while driving on the road or during visual inspection.

Wheel bearings are designed for smooth rotation with minimal friction, so any irregularities in rotational speed may indicate wear, lack of lubrication, or internal damage.

Rotating the wheel by hand allows you to distinguish noise and feel, making it easier to compare all wheels and identify which bearing may be bad.

1. Slowly rotate the wheel and listen for wear or roughness

With the vehicle safely raised and supported on jack stands, gently rotate the wheel clockwise and anti-clockwise.

While rotating, listen carefully for any grinding, clicking, or rough scraping sounds coming from the hub.

A healthy wheel bearing should rotate smoothly and quietly without any obvious resistance.

Wear or uneven motion often indicates that the rolling elements inside the bearing are worn, contaminated, or lacking proper lubrication.

This step is particularly useful because it reproduces the mechanical motion experienced by the bearing during driving in a controlled and observable manner.

By rotating the wheel slowly, you can detect even subtle vibrations that may not be noticeable at high speeds.

2. Comparing Sound and Feel Between Four Wheels

After rotating one wheel, repeat this process for all four wheels to identify differences in sound or feel.

Comparing each wheel helps confirm which bearing is causing the problem and eliminates false positives caused by tires, brakes, or suspension components.

Bad bearings often feel rougher than others or produce more audible noise, while healthy bearings rotate smoothly and quietly.

Knowing which wheel is spinning roughly or producing unusual sounds helps pinpoint the location of the problem and ensure a more accurate diagnosis.

How to Use a Mechanic’s Stethoscope or Screwdriver

After turning the wheel by hand, a more accurate way to detect wheel bearing noise is to use a mechanic’s stethoscope or a simple screwdriver.

This step allows you to hear the bearing directly as it operates and detect internal noises that may not be easily heard from outside the vehicle.

Wheel bearings contain metal balls or rollers inside the races and as they wear or lose lubrication, these components produce vibrations and grinding sounds.

Using a stethoscope or screwdriver can help you identify which bearing is failing even before you notice the noise while driving.

1. Place a probe on the hub or knuckle near each wheel bearing while turning the wheel

For this check, safely raise the vehicle on jack stands.

Place the tip of the mechanic’s stethoscope directly on the steering knuckle near the wheel hub or bearing.

If a stethoscope isn’t available, a long screwdriver can be used.

You can do this by pressing its metal end against the hub and placing your ear on the handle.

Holding the probe in place, slowly rotate the wheel.

Vibrations caused by worn bearings will be transmitted through the metal and heard in the stethoscope or screwdriver handle.

This method can help you hear distinctive grinding, humming, or rattling sounds that confirm internal bearing wear.

2. Listening for Differences in Noise or Vibration Between Wheels

After testing each wheel, compare the sounds and vibrations between the four wheels.

A healthy bearing will produce very little noise and rotate smoothly, while a worn bearing will produce a distinctive noise that is louder or harsher than the others.

Observing these differences can help you determine which side or corner of the vehicle has the problem.

Sometimes the sound can be faint, so it’s important to listen carefully and compare each wheel.

This technique is specially useful for detecting early-stage bearing wear, signs of which may not yet be visible due to road noise or physical movement.

Read More:

What are the Advanced Diagnostics – Truly Optional

For those looking for a more precise and professional approach to diagnosing wheel bearing noise, advanced diagnostic tools can provide highly accurate results.

These methods are specially useful when the noise is mild, intermittent, or difficult to identify through basic road tests and physical inspections.

Advanced diagnostics help mechanics or knowledgeable car owners pinpoint the exact location of a faulty bearing, ensuring accurate repairs and avoiding unnecessary part replacement.

1. Using a Chassis Ear System to Accurately Locate Noisy Bearings While Driving

Chassis Ear is an electronic diagnostic system that uses multiple microphones mounted near each wheel.

These microphones transmit sound to a control unit, allowing the listener to hear each wheel individually while the vehicle is moving.

As the car moves, this system amplifies and isolates the noise produced by the wheels, making it much easier to identify which bearing is worn.

This method is specially useful when road conditions or engine noise make it difficult to hear the bearings using traditional methods.

Using a chassis ear while driving can reveal the actual condition of wheel bearings, indicating how they perform under load, speed and cornering.

2. Checking ABS sensor readings if the bearings have integrated sensors

Modern vehicles often have wheel bearings with integrated ABS (anti-lock braking system) sensors.

These sensors monitor wheel speed and can detect irregular rotation caused by worn bearings.

Using an OBD-II scanner or diagnostic tool, you can check for error codes related to the wheel speed sensor or ABS system.

Fluctuations in sensor readings or stored ABS codes may indicate excessive play or poor rotation in the bearings.

This provides an additional layer of confirmation and helps with early detection before excessive bearing wear occurs, potentially posing a safety risk.

How to Interpret the Results

After completing all the steps of testing, inspecting and listening to the wheels, the next important step is interpreting the results.

Understanding the meaning of the noise helps you determine whether the problem actually originates from the wheel bearings or from another component, such as tires, brakes, or suspension parts.

Misdiagnosing the source of the noise can lead to unnecessary repairs, wasted time and additional costs.

Careful observation of how the sound behaves under different conditions—such as changing speed, cornering and braking—provides reliable clues for an accurate diagnosis.

1. Identifying Whether the Noise Is Actually Coming From the Wheel Bearings or Another Component

To confirm that the noise is due to the wheel bearings, consider how the sound changes with speed, steering and load.

Wheel bearing noise typically increases as the vehicle accelerates and often becomes louder or changes pitch when the steering wheel is turned.

This occurs because the bearings are subjected to greater pressure on the side opposite to the wheel’s turn, causing the worn rollers or balls inside to vibrate more intensely.

In contrast, sounds originating from other components behave differently.

Tires with uneven wear or cupping produce a rhythmic or continuous sound that remains virtually unchanged during turns.

Brake noise typically occurs only when braking and is absent during coasting.

Observing these patterns can help diagnose the problem and avoid confusing wheel bearing noise with other mechanical problems.

2. Comparison of Sound Characteristics

Wheel bearing noise is distinctive in that it increases with speed and responds to changes in steering direction.

This sound often begins as a slight hum or rumble at low speeds and becomes louder and deeper as the vehicle accelerates.

However, tire noise, due to tread design or uneven wear, maintains a regular, rhythmic pattern and does not change much during turns.

Brake noise occurs only during braking and typically manifests as squealing, scraping, or grinding and disappears when the vehicle is moving without braking.

By comparing the sound characteristics in these ways, you can accurately determine whether the source is the wheel bearing or another component.

What to do if You Confirm Wheel Bearing Noise

It’s crucial to ensure that your vehicle’s wheel bearings are not worn or deteriorating, as this directly impacts both vehicle safety and performance.

Ignoring this problem can lead to serious consequences, including increased friction, overheating and ultimately, wheel seizure.

A stuck wheel can completely damage the hub assembly, leading to loss of vehicle control, accidents, or serious damage to suspension and braking components.

Timely identification and replacement of the bearing is essential to prevent these dangerous consequences and maintain smooth, safe driving.

1. The Importance of Timely Bearing Replacement to Prevent Wheel Seizure or Hub Assembly Damage

Wheel bearings are designed to rotate smoothly under load with minimal friction.

Once they begin to wear, friction increases, generating heat that can damage the bearing and the surrounding hub assembly.

If the bearing isn’t replaced promptly, the metal rollers or balls inside the races can break or wear out, causing the wheel to lock up or sway.

This not only damages the hub and wheel studs, but also puts additional stress on suspension and brake components, increasing repair costs.

Timely replacement ensures the wheel continues to rotate freely and safely, while maintaining the integrity of related components.

2. Can you drive temporarily, or do you need immediate repair?

In some cases, a worn bearing may only produce a slight humming or rumbling sound, allowing limited driving at low speeds for short distances.

However, any grinding, rattling, or severe vibration indicates that the bearing is rapidly deteriorating.

Driving under such conditions is risky, as the bearing could suddenly fail, causing the wheel to jam or the hub to break.

For safety, it’s recommended that you limit your vehicle to essential trips only and avoid highway or high-speed travel until the bearing is repaired.

Understanding the severity of the noise and observing its changes with speed or cornering helps determine whether immediate attention is needed.

3. The Difficulty of Self-Replacement and When to Seek Professional Help

Replacing a wheel bearing can be a complex and laborious task, often requiring specialized tools such as a press or bearing puller, a suitable torque wrench and precision alignment tools.

For most car owners, attempting to replace a bearing yourself without experience can result in incorrect installation, which can worsen the problem or create new safety hazards.

Professional mechanics have the knowledge, tools and experience to replace the bearing correctly, ensuring that the hub assembly and suspension components are not damaged during the process.

If you’re unsure or don’t have the right tools, it’s always safest to seek professional assistance to guarantee both the quality of the repair and your personal safety.

How to Maintain Wheel Bearings to Extend Its Life

Properly maintaining wheel bearings can significantly extend their lifespan and prevent costly repairs.

Wheel bearings are critical components that bear the vehicle’s load and help the wheels rotate smoothly.

Neglecting them can increase friction, overheat and ultimately lead to failure, impacting safety, fuel efficiency and ride comfort.

By following a few simple maintenance measures, you can ensure your bearings remain in good condition and continue to deliver reliable performance for many years.

So, recent research actually shows that when you only listen the bearing noise, then you may miss early bearing damage, which is why you should combine vibration sensors with audio recordings and modern pattern-recognition algorithms that gives a more sensitive early warnings, that’s why professional shops actually uses both acoustic listening and vibration analysis when a subtle hum is reported to them.[¹]

1. Maintain Correct Tire Pressure and Alignment

Maintaining correct tire pressure and wheel alignment reduces uneven pressure on wheel bearings.

Over- or under-inflated tires cause uneven load distribution, while misaligned wheels force bearings to work harder to compensate for the uneven rotation.

Both conditions cause wear and heat, which can reduce bearing life.

Regularly checking and adjusting tire pressure and alignment according to vehicle manufacturer recommendations helps keep bearings rotating smoothly and reduces the risk of premature wear.

2. Avoid frequent driving in deep water or mud

Wheel bearings are designed to operate in relatively clean and dry conditions.

Driving in deep water, mud, or highly contaminated areas introduces dirt, debris and moisture into the bearing seals.

Water can wash away the lubricant inside, while dirt and dust create friction, damaging the bearing surface.

Frequent driving in such conditions increases the risk of premature wear and corrosion.

Limiting such driving or thoroughly cleaning and inspecting the wheels afterward can prevent bearing damage from contaminants.

3. Check the proper torque on the lug nuts after tire installation

Properly torqued lug nuts are essential for wheel stability and bearing health.

Loose or overtightened lug nuts put uneven pressure on the hub and bearings, which can lead to premature wear and even mechanical failure.

After any tire installation, wheel rotation, or brake service, it’s important to check that all lug nuts are tightened to the manufacturer’s specified torque.

This simple step ensures the wheel remains securely mounted and the bearings operate at optimal conditions.

4. Regular Inspection Intervals

Regular wheel bearing inspection is one of the most effective ways to detect problems early.

Even if the vehicle runs smoothly, bearings can gradually deteriorate without any obvious symptoms and can become serious.

Checking for unusual sounds, irregular rotation, or slight looseness at regular intervals—such as every 10,000 to 15,000 miles or during regular tire rotations—helps detect problems before they become serious.

Regular inspection, along with proper maintenance practices, maximizes the lifespan of wheel bearings and maintains vehicle safety, stability and efficiency.

Conclusion – How to Check Wheel Bearing Noise

Yes, wheel bearings hidden component inside the hub, but if they are worn out then you can feel your vehicle’s smoothness is gone and safety falls in danger area, even you can hear a faint hum or subtle vibration from your wheels which you can take it as a early warning signs to prevent some serious damage later on.

In fact, they allow the wheels to rotate smoothly while supporting the car’s weight and even minor wear can increase vibration, noise and friction.

Early detection of wheel bearing noise through a combination of road testing, visual inspection, physical examination and listening devices can prevent serious damage to the hub, suspension and braking system.

Proper maintenance—such as maintaining correct tire pressure, avoiding contact with water or mud, ensuring lug nuts are properly torqued and regular inspections—can significantly extend the life of your wheel bearings.

Timely replacement of worn bearings isn’t just a matter of convenience; it’s essential for safe driving and avoiding costly repairs.

Understanding how to identify, interpret and respond to wheel bearing problems helps vehicle owners maintain both safety and performance.

So, that’s it from this one and you can comment below for more information.

Frequently Asked Questions

Q1. What are wheel bearings and why are they important?

Answer: Wheel bearings are small mechanical components that help your vehicle’s wheels rotate smoothly with very little friction. They are located inside the wheel hub and support the car’s weight while keeping the wheels aligned. They are essential because they make driving smooth and safe. Worn or damaged wheel bearings can cause noise, vibration, uneven tire wear, reduced fuel efficiency and, in severe cases, wheel failure.

Q2. How can I tell if my wheel bearings are bad?

Answer: Bad wheel bearings often produce distinctive noises such as humming, grinding, rattling, or rattling. These sounds usually increase with speed and vary with steering wheel rotation. You may also notice slight vibration or looseness in the wheel, specially when you rock it back and forth. Initial symptoms may be mild, such as a slight hum at highway speeds, while more severe wear can lead to a louder, more persistent noise.

Q3. Can I drive with a bad wheel bearing?

Answer: Driving with a bad wheel bearing is not recommended. Initially, you may be able to drive short distances at low speeds, but as the bearing wears out, the wheel may become stuck or wobble. This can lead to unsafe operation, damage to the hub assembly, suspension and brakes, or even a wheel becoming loose while driving. If you notice any humming, wear, or rough movement, limiting your driving and replacing the bearing as soon as possible is the safest option.

Q4. How often should I check my wheel bearings?

Answer: Wheel bearings should be inspected regularly, specially during routine maintenance or tire rotation, which typically occurs every 10,000 to 15,000 miles. Even if the car seems quiet, small signs like vibrations or unusual noises shouldn’t be ignored. Regular inspections help detect wear before it becomes a serious safety hazard.

References:

[1] Fault Detection of Wheelset Bearings through Vibration-Sound Fusion Data Based on Grey Wolf Optimizer and Support Vector Machine

https://www.mdpi.com/2227-7080/12/9/144

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.