Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

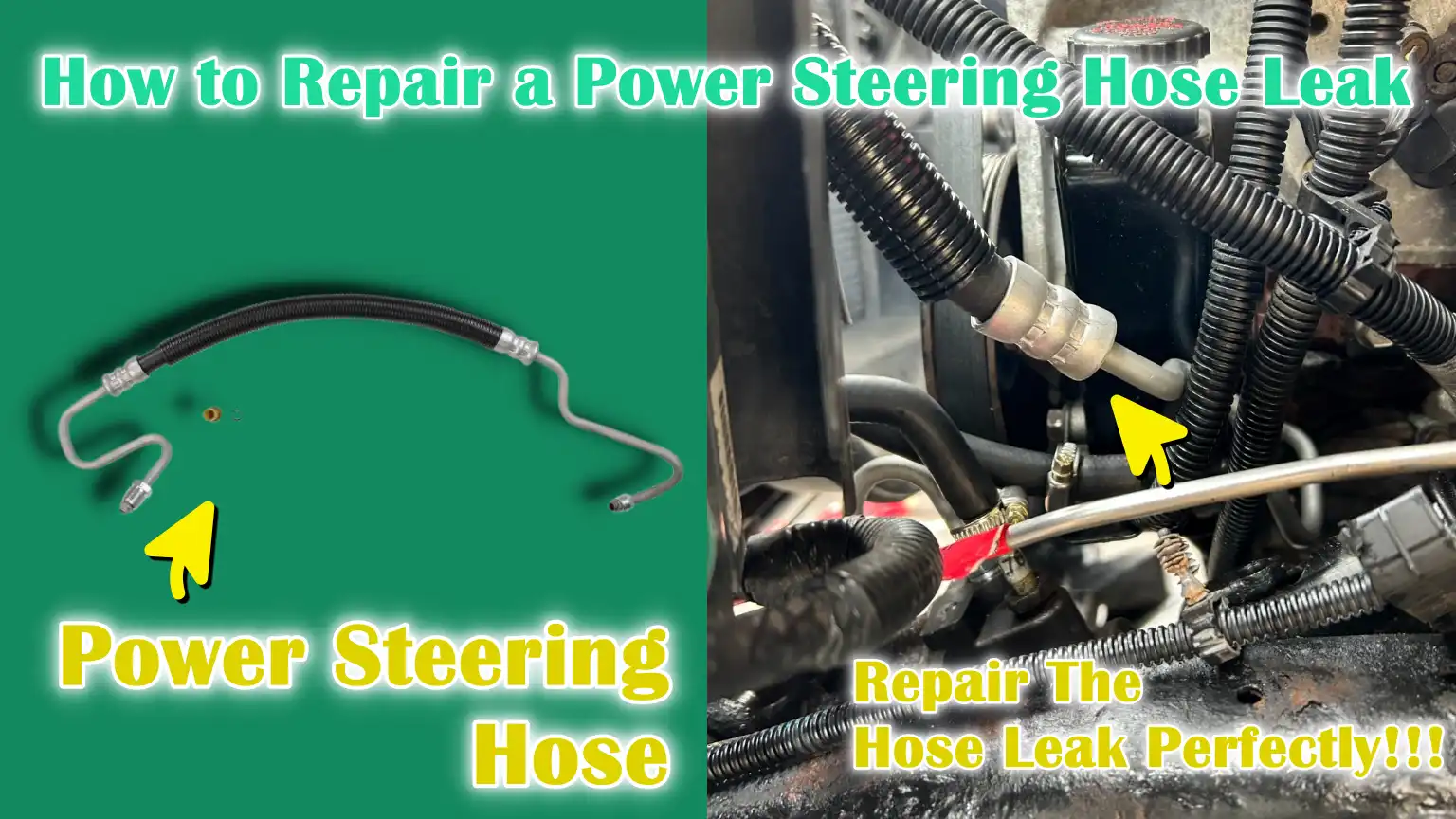

Basically, even a small drip of power steering fluid can turn into a failed pump after some time, yeah its unfortunate that’s why you need to repair a power steering hose leak.

Yes, a power steering hose leak is known as common problems in older and high-mileage vehicles, also it is actually sign that your steering systems has problem and can fail if not taken care of.

Now-a-days, modern power steering systems work under very high pressure even between 1,000 to 1,500 PSI as well: which is why if there’s even a small crack or loose fitting in a hose then it can quickly leads to the lfuid loss, stiff steering and it can possibly lead to the pump damage as well.

Even, there’s industry data that shows that more than 70% of the power steering failures actually starts with the worn or aged hoses: and mostly because of the heat, pressure and rubber breakdowns over the period of use and time.

You can notice something like: noises, hard turning or red fluid under the vehicle, but it is quiet possible that many don’t even realize that a leaking hose can also cause the pump to run dry and overheat within the matter of minutes, that leads to the expensive repairs as well.

Now, this is the proper guide on How to Repair a Power Steering Hose Leak, so that you can easily fix that issue quiet effortlessly.

Common Symptoms of a Power Steering Hose Leak

1. Red or Pink Fluid Appearing Underneath the Vehicle

When a power steering hose starts leaking, one of the first and most reliable signs is seeing red or pink fluid on the ground beneath the car.

Power steering fluid has a distinct color and a slightly oily texture, making it easy to identify if you know what to look for.

This is usually because heat and pressure cause the hose to crack over time.

Even a small leak after parking overnight can cause visible spots.

Recognizing this sign early helps prevent the steering pump from running dry, which could cause serious damage.

2. Low Power Steering Fluid Reservoir Level

Another common symptom is a dropping fluid level inside the reservoir.

The power steering system is designed to operate in a closed loop, which means that the fluid should never run low unless there is a leak.

If the level drops below the set mark, the system cannot generate enough pressure to support proper steering.

Regularly checking the reservoir can help detect hose problems early, specially in older vehicles where hoses wear out quickly.

3. Noise when turning the steering wheel

Noise when turning the steering wheel often means air has entered the system because fluid is escaping from a leaking hose.

Power steering systems rely heavily on proper fluid pressure and when air bubbles replace fluid, the pump cannot function properly.

This noise becomes louder during sharp turns, when the system requires the most pressure.

Repairing hose leaks quickly prevents the pump from overheating or damaging the steering.

4. Steering Stiffness or Jerking

A leaking power steering hose can make it difficult to turn the steering wheel, specially at low speeds.

This occurs because the system cannot maintain the necessary hydraulic pressure to assist the driver in steering.

As fluid leaks, steering assist becomes inconsistent, causing the wheel to feel heavy at times and normal at other times.

This stiffness isn’t just a nuisance—it reduces control and increases the risk of unsafe driving conditions.

5. Burning Oil Smell from the Engine Bay

When power steering fluid leaks onto hot engine parts, such as the exhaust manifold or serpentine belt, it produces a distinct smell of burning oil.

Power steering fluid is petroleum-based, so when it heats up, it emits a strong, easily recognizable odor.

This smell is a warning that fluid may be leaking near high-temperature parts, which could damage belts and, if ignored, could pose a fire hazard.

6. Hissing sound at high pressure points

Hissing or a light spray sound from the engine area while steering often indicates a small hole or crack in a high-pressure hose.

The pressure within the line can exceed 1,000 PSI and when the hose weakens, fluid can escape as a fine mist.

This sound is usually most noticeable when the wheel is spinning rapidly, as this is when the system is under the greatest load.

Recognizing hissing sounds early helps prevent sudden hose failure, which can lead to rapid fluid loss and immediate steering problems.

Tools

| Tool / Material | What It Is | Why You Need It |

|---|---|---|

| Replacement pressure or return hose | A new hose designed to handle high-pressure or low-pressure flow. | It is used to replace leaking or damaged old hoses. |

| Power steering fluid (maker-recommended type) | This special oil helps the steering system function smoothly. | After replacing the hose, it was necessary to refill the system. |

| Hose clamps (for return hose only) | Small metal rings that hold the return hose firmly in place. | This helps prevent leaks and keeps the hose from slipping. |

| Wrenches and ratchets | Hand tools used for loosening and tightening nuts and bolts. | This requires removing and reinstalling hoses and fittings. |

| Drain pan and shop towels | A shallow container and absorbent cleaning cloths. | It is used to contain leaking liquids and to safely clean up spills. |

| Jack and jack stands | Devices that lift a car and hold it safely in the air. | It was necessary to safely access the hose pipes located under the vehicle. |

| Safety gloves and eye protection | protective equipment for hands and eyes. | This helps prevent injuries from sharp parts or splashes of liquids. |

| Line wrench (flare nut wrench) | A special wrench designed for pressure line fittings. | Prevents damage to nuts on the ends of high-pressure hoses. |

| Hose cutter or utility knife | A sharp tool used to cleanly cut pipe material. | Helps trim the hose to the correct length when needed. |

| Torque wrench | A device that tightens bolts to the exact pressure required. | This ensures that the fitting is tightened correctly without causing any damage. |

What are The Safety Precautions

1. Let the Engine Cool Completely

It’s crucial to let the engine cool completely before working on the power steering system.

Power steering hoses often pass near hot engine parts, such as the exhaust manifold and engine block, which can remain extremely hot for long periods of time even after the car is turned off.

Hot surfaces can cause burns within seconds and hot power steering fluid can also be released if the system is opened too quickly.

Allowing the engine to cool not only protects your skin but also makes it easier to handle hoses, fittings and tools without heat stress.

2. Use jack stands; never rely on a jack alone

When lifting a vehicle, using a jack alone is unsafe because jacks are designed to lift the car, not to hold it for long periods.

They can suddenly fail due to lack of pressure or uneven surfaces.

However, jack stands are designed to lock the car in place and provide stable support while you work underneath.

Using jack stands greatly reduces the risk of the vehicle falling, which could cause serious injury.

Ensuring strong support is one of the most important steps when repairing hoses underneath the vehicle.

3. Keep fluid away from belts to prevent slipping.

Power steering fluid is very slippery and if it gets on the serpentine belt or pulley, it can reduce the belt’s traction.

This can affect many of the car’s systems, including the alternator, water pump and power steering pump.

Belt slippage can cause a loud squealing noise, reduced performance, or even breakage if it gets too wet.

Keeping fluid away from the belt can prevent these problems and keep the engine running smoothly during and after repairs.

4. Clean up spills immediately because power steering fluid can catch fire.

Power steering fluid is petroleum-based, which means it can ignite if it comes into contact with very hot parts like the exhaust manifold.

Cleaning up spills is important not only for safety but also to prevent damage to rubber parts, hoses and belts, which can weaken if exposed to oil for extended periods.

Cleaning up spills immediately also helps you pinpoint the leak, making repairs more accurate and reducing further mess.

5. Disconnect the battery to work safely around belts.

Disconnecting the car’s battery isn’t necessary for every repair, but it’s a smart safety step when working around belts, pulleys and moving parts.

If the engine is accidentally started or electrical components are activated, belts can suddenly rotate and cause injury.

Disconnecting the battery eliminates this risk by ensuring the engine can’t start while your hands are near sensitive areas.

This simple step adds an extra layer of safety, specially for beginners or anyone who feels uncomfortable working around moving parts.

How to Find Leaks

1. Check the Hose Routing from the Pump to the Steering Rack

To locate a power steering hose leak, follow the entire route of the hose from the power steering pump to the steering rack.

This hose often passes through tight spaces and around hot engine parts, which can cause wear over time.

By carefully examining the entire length of the hose, you can locate areas where it is rubbing against metal, exposed to heat, or bent too sharply.

These stress points are common places for leaks to originate because pressure within the system can reach very high levels.

Slow or fast leaks often begin where the hose has weakened due to prolonged heat or movement.

2. Check for Wetness in High-Pressure Line Fittings

The high-pressure line carries fluid from the pump at pressures exceeding 1,000 PSI, making leaks more likely if the fittings are loose or worn.

To check them, carefully examine the metal connectors at both ends of the hose.

Even a slight wetness or a shiny fluid film can indicate a leak.

High-pressure fittings don’t fail suddenly, but often start with small leaks that grow over time.

Early detection can prevent a major drop in pressure and prevent pump damage.

3. Check for cracks or swelling in the return hose

The return hose carries fluid back to the reservoir at low pressure, but it’s usually made of soft rubber that can dry out and crack as the vehicle ages.

Heat from the engine can cause swelling, soft spots, or bulges in the hose.

These signs indicate that the rubber is deteriorating and may soon begin leaking.

As return hoses don’t use crimped metal fittings, they often leak from worn rubber rather than the connections.

Inspecting the entire surface of the hose helps you identify weak spots before they develop into major leaks.

4. Check for fluid at clamps, crimped fittings and bends

Leaks often occur where the hose changes shape or where it is held in place by clamps or crimped metal ends.

Crimped fittings can loosen over time as heat causes the metal to expand and contract.

Bends are also common trouble spots because bent parts are subjected to greater pressure and repeated movement from engine vibration can weaken them.

If you notice dark spots, shiny wet areas, or spots of dried fluid, it means fluid is slowly leaking.

5. Clean the area with brake cleaner to confirm the source

Because power steering fluid can flow between parts and inadvertently drip somewhere, cleaning the area is one of the best ways to confirm the actual source of the leak.

Brake cleaner works well because it removes oil quickly and dries without leaving any residue.

After cleaning, run the engine for a while and carefully observe where fresh fluid appears.

This simple step makes leak detection more accurate and prevents misdiagnosis, saving time and money during repairs.

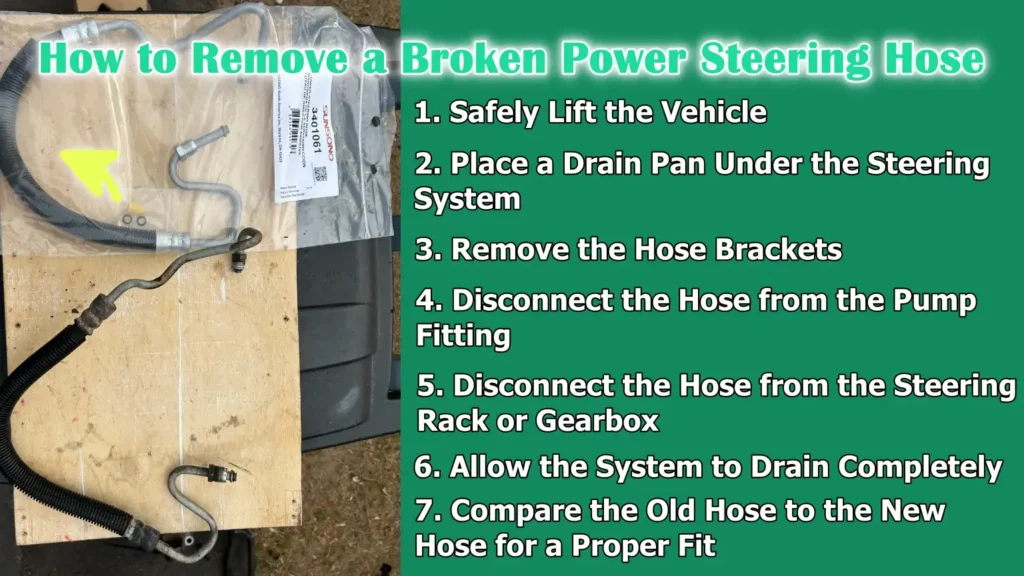

How to Remove a Broken Power Steering Hose

1. Safely Lift the Vehicle

Removing a power steering hose often requires working underneath the car, so lifting safely is the first and most important step.

The vehicle should be raised to a flat surface using a jack and then supported with jack stands to keep the car completely stable.

The power steering hoses are located under the engine bay and lifting them properly allows access to fittings, clamps and brackets without straining your body.

Safely lifting also reduces the risk of accidental falls, which could cause serious injury or damage to the vehicle.

2. Place a Drain Pan Under the Steering System

As soon as the hose becomes loose, power steering fluid will begin to leak, so placing a drain pan underneath collects all the fluid.

This prevents the fluid from spilling onto the ground or engine parts that could be damaged by contact with the oil.

Power steering fluid is very slippery and can make a work area hazardous if spilled.

Collecting old fluid in a pan makes it easy to dispose of and keeps the work area clean and safe.

3. Remove the Hose Brackets

Many vehicles have metal or plastic brackets that secure the power steering hose in place.

These brackets prevent the hose from moving or rubbing against engine parts, but they must be removed before removing the hose.

Removing these brackets ensures that the hose can be easily removed without force or bending.

This also makes installing a new hose later easier because the path is clear and visible.

4. Disconnect the Hose from the Pump Fitting

The power steering pump fitting is usually connected to a threaded metal connection for the high-pressure hose or a simple clamp for the return hose.

Disconnecting the hose at this point will drain the fluid and expose one end of the hose.

A line wrench may be needed to prevent damaging the nuts on the high-pressure fittings, while the return fittings can be loosened by removing a clamp.

This step is essential because the pump is the main source of fluid pressure and removing the hose here will drain the system.

5. Disconnect the Hose from the Steering Rack or Gearbox

The other end of the hose connects to the steering rack or gearbox, depending on the type of steering system the vehicle uses.

Disconnecting this connection completes the removal process and drains any remaining fluid in the line.

The steering rack connection can be difficult to access because it is located deep in the engine bay, but disconnecting it carefully can prevent thread breakage or damage to surrounding components.

6. Allow the System to Drain Completely

After removing both ends of the hoses, any remaining power steering fluid will continue to drain.

Allowing it to drain completely prevents the old, contaminated fluid from mixing with the new fluid later.

Old fluid may contain metal shavings, dirt, or broken additives that can shorten the life of the new hose and damage the pump.

Allowing the system to drain completely helps to clean the car and prepare it for reinstallation.

7. Compare the Old Hose to the New Hose for a Proper Fit

Before installing a new hose, it’s important to compare it to the old hose to ensure that the length, size, fittings and bends match.

Power steering hoses are designed to follow specific paths within the engine bay and even slight differences in length or angle can cause rubbing, bends, or incorrect pressure flow.

Inspecting the new hose before installation prevents future leaks, increases reliability and ensures the hose fits exactly as intended by the manufacturer.

Read More:

How to Install a New Power Steering Hose

1. Install the Hose According to the Factory Route

When installing a new power steering hose, it’s important to follow the routing of the original hose.

Car manufacturers design the routing to keep the hose away from moving parts, sharp edges and high-heat areas, which could damage it.

Following the factory route ensures proper fluid flow and eliminates bends and twists that could reduce pressure.

This also reduces the risk of the hose rubbing against engine components, which can wear out the rubber over time and cause new leaks.

2. Hand-tighten the fittings first to avoid cross-threading

Before using any tools, hand-tighten the fittings on both ends of the hose.

This step helps prevent cross-threading, which occurs when the threads are not properly aligned.

Cross-threading can damage fittings and cause leaks, even when fully tightened.

Hand-tightening ensures that the threads are properly seated, making the final tightening more secure and precise.

This also reduces the chance of stripping the threads, which could require costly repairs.

3. Use a line wrench to secure high-pressure fittings

High-pressure power steering hoses use strong metal fittings, which must be tightened with a special tool called a line wrench.

This wrench grips the fitting at a wider angle than a regular wrench, preventing rounded corners.

Proper tightening is essential because the high-pressure portion of the system can handle fluid pressures exceeding 1,000 PSI.

A secure connection ensures that the system can handle this pressure without leaking, spraying, or loosening under normal driving conditions.

4. Use a good-quality clamp for the return hose.

The return hose operates under low pressure and is typically connected with clamps rather than threaded metal fittings.

Using strong, high-quality clamps ensures the hose remains securely attached even when the engine vibrates or the fluid heats up.

Cheap or worn clamps can loosen over time, causing gradual leaks or even complete separation of the hose.

Using good clamps ensures a secure seal and keeps the return hose stable throughout operation.

5. Ensure the hose is not rubbing against metal or heat sources.

Once the new hose is installed, ensure it does not touch sharp edges, rotating parts, or hot surfaces such as the exhaust manifold.

Constant rubbing can wear down the rubber in the hose and heat can weaken the hose material, causing it to swell or crack.

Ensuring that the hose is securely installed helps extend its life and protects the system from unexpected leaks.

Properly installed hoses improve safety and system performance.

6. Reinstall Brackets and Retaining Clips

Many power steering hoses are held in place by brackets and clips that secure them in place during engine movement and vibration.

Reinstalling these supports is essential to maintain the original routing and prevent the hose from moving.

Without these brackets, the hose may move in unsafe areas or rub against other parts.

Properly installing the hose guarantees consistent fluid flow and long-term reliability.

7. Tighten the Fittings to the Manufacturer’s Recommended Torque

The final step is to tighten all fittings to the correct torque specified by the manufacturer.

Using the correct torque ensures fittings are tight enough to prevent leaks, but not so tight that they damage the threads or crush the sealing surface.

Overtightening can cause parts to crack, while undertightening can cause fluid to escape under pressure.

Using a torque wrench helps maintain the correct balance, resulting in a secure, leak-free seal that can withstand the high pressures of everyday driving and power steering systems.

How to Refill the Power Steering System

1. Add the correct power steering fluid to the reservoir

After installing the new hose, the next important step is to add the correct power steering fluid recommended by the vehicle manufacturer.

Different vehicles use different types of fluid and using the wrong type can cause poor lubrication, pump noise, or long-term damage to the seals within the system.

The reservoir is usually marked with minimum and maximum lines, making it easy to see how much fluid is needed.

Adding the correct fluid restores the hydraulic pressure the system relies on and prepares the system for safe operation once the bleeding process begins.

2. Fill slowly and check for leaks at fittings

Fluid should be added slowly so you can monitor the level and look for any signs of leaks around the newly installed hoses and fittings.

Filling too quickly could cause the reservoir to overflow or trap air inside the system.

By filling slowly, you can also check for fluid leaks from the high-pressure or return connections.

This close inspection is important, as even a small leak can cause pressure loss or pump failure after the vehicle is running.

Slow filling helps ensure that all connections are properly sealed before pressure returns to the system.

3. Keep the Cap Closed for the Initial Bleeding Step

During the first stage of bleeding, the reservoir cap should be closed so that trapped air can be easily released as the fluid begins to circulate through the system.

Air pockets inside power steering lines can cause noise, steering jerks and low pressure, so allowing air to rise and bleed from an open reservoir is an essential part of restoring smooth steering performance.

Keeping the cap closed also makes it easier to monitor the fluid level, which can drop rapidly as air is expelled and replaced with fluid.

Once the initial bleeding is complete and the level is stable, the cap can be reinstalled to completely seal the system.

How to Bleed the Power Steering System

1. Raise the Front Wheels Off the Ground

Bleeding the power steering system is easier and safer when the front wheels are raised, as this removes the vehicle’s weight from the steering components.

With the wheels off the ground, the steering wheel can rotate freely without putting pressure on the pump or new hoses.

This allows fluid to drain easily from the lines and helps remove trapped air from the system.

Raising the front wheels also prevents unnecessary wear on the tires and steering rack during the bleeding process.

2. Turn the steering wheel from lock to lock ten to twenty times

Full rotation of the steering wheel from one end to the other forces fluid through the entire power steering system.

This motion pushes air pockets toward the reservoir, where they can be released.

This is important to do repeatedly, as air can become trapped in high spots or bends in the hose.

The lock-to-lock motion creates a consistent flow of fluid, which is essential for maintaining proper hydraulic pressure and restoring normal steering feel.

This step should be performed slowly to avoid foaming the fluid.

3. Watch the Fluid Level Decrease and Refill as Needed

As air is released from the system and fluid fills the hoses and steering rack, the fluid level in the reservoir will automatically decrease.

Keeping a close eye on the level helps prevent the pump from running dry, which could cause damage.

Slowly refilling ensures that the reservoir never becomes empty and that fresh fluid replaces the air that escapes.

Keeping the reservoir properly filled during this step is crucial for a complete and effective bleed.

4. Start the Engine and Repeat the Turning Process

When the first stage of bleeding is complete with the engine off, start the engine to allow the pump to circulate the fluid.

The power steering pump builds pressure, which helps expel any remaining air during the manual turning phase.

Turning the wheel from lock to lock again with the engine running completes the process by circulating the fluid at full system pressure.

This makes the steering wheel feel smooth and quiet as the last air bubbles are expelled from the lines.

5. Pay attention to air bubbles from the reservoir

During bleeding, as air is vented from the system, small or large bubbles will rise to the top of the reservoir.

It is important to pay attention to these bubbles as they confirm that air is being released.

This process should be continued until no new bubbles appear and the fluid surface becomes calm.

Trapped air in the power steering system can cause noise, steering damage and put pressure on the pump, so it is important to ensure that all bubbles are removed for proper operation.

6. Recheck for leaks and secure the reservoir cap

After the system has been completely bled, the fittings, hoses and clamps should be rechecked for any new leaks.

This final check ensures that the newly installed hoses are properly sealed and can maintain system pressure.

When everything appears dry and secure, the reservoir cap should be properly tightened to seal the system and prevent fluid loss.

Securing the cap also ensures the correct pressure balance within the reservoir, maintaining optimal steering performance.

How to Test and Perform Final Inspection

1. Lowering the Car for Testing

The first step in the testing phase is lowering the car back to the ground after the repairs are complete.

To check the steering system under normal driving conditions, lower the car slowly and safely.

This ensures that the new hoses work properly when the car is fully loaded.

2. Road Testing

A short and careful road test helps you understand how well the power steering system is functioning after the hoses have been replaced.

While driving, the steering wheel should turn smoothly without any noise, stiffness, or vibration.

If the steering feels light, quiet and easy to control, it usually means the system is receiving the correct amount of fluid pressure.

3. Rechecking the Fluid Level

After the road test, park the car, turn off the engine and open the power steering fluid reservoir to recheck the fluid level.

Sometimes, small air bubbles escape from the system during driving, causing the fluid level to drop slightly.

Topping it up ensures that the pump and steering parts remain properly lubricated.

4. Rechecking Hoses and Fittings

It’s important to recheck hoses and all fittings to ensure there are no leaks.

Check every connection point for moisture, oil stains, or signs of leakage.

Even a small wet spot can turn into a major leak over time, so any problem should be repaired immediately to prevent damage to the pump or steering rack.

5. Cleaning Up Remaining Spilled Fluid

The final step is to clean up any fluid that may have been spilled during installation or testing.

Power steering fluid can damage rubber parts, soften hoses and create slippery areas in the engine bay.

Removing every trace of fluid keeps the vehicle safe, reduces odors and prevents long-term damage to surrounding parts.

So, When You Should Consult to the Professional

1. Rack Seal Leak

Sometimes, power steering leaks aren’t from the hoses, but from the seals inside the steering rack.

These seals are responsible for containing high-pressure fluid inside the rack, ensuring smooth steering.

When they wear out, fluid typically leaks from the rubber boots at the ends of the rack.

Repairing or replacing rack seals requires special tools and precise alignment, so this type of problem usually requires a trained mechanic.

2. Bad Pump or Pulley

If the power steering pump shows signs of malfunction, such as noise, metal fragments in the fluid, or difficulty building pressure, it may need to be repaired or replaced.

The pulley attached to the pump should also rotate smoothly and remain perfectly aligned with the belt.

Even slight movement can wear out the belt or impair steering assist.

As replacing a pump often involves properly bleeding the system, checking belt tension and sometimes removing other engine parts, a professional can perform it more safely and accurately.

3. Excessive Contamination in the Fluid System

When the steering system is heavily contaminated, such as sludge, metal particles, or burnt fluid, simply replacing the hose may not be enough.

Dirty fluid can damage the pump, steering rack and valves over time.

A mechanic can flush the entire system using specialized equipment to remove the contaminants and replace them with clean fluid.

This ensures that the new hose and the rest of the steering system are not damaged after the repair.

4. Improperly Flared Fittings or the Need for Custom Hose

Some vehicles use metal lines or high-pressure hoses that have special flare angles or unique end fittings.

If these fittings are not sized correctly or if the hose requires custom manufacturing, the parts may not seal properly and leak under high pressure.

Making or repairing these fittings requires hydraulic flaring tools and knowledge of the correct angles and pressure ratings.

To ensure that the connections are made according to factory standards, a professional mechanic or hydraulic hose shop is usually the best option.

How to Maintain to Prevent Further Leaks

Also, NHTSA shows that if heat and poor clamp routing can cause behind the power steering feed hoses to crack, lead and in some of the vehicles it can create smoke or fire risk as well.[¹]

1. Check the Power Steering Fluid Level Monthly

Regularly checking the power steering fluid level helps you detect early signs of leaks before they become a major problem.

When the level drops below the recommended mark, the pump can draw air, causing noise, harsh steering and increased wear on internal parts.

A quick check every month ensures that the system always has enough fluid to operate smoothly without any pressure.

2. Check the Hoses at Every Oil Change

It’s a good practice to visually inspect the power steering hoses every oil change.

Over time, heat and pressure can cause cracks, soft spots, or swollen areas in the hoses.

Early detection allows you to replace hoses before they burst or leak significantly, preventing sudden steering failure and costly damage to the pump or rack.

3. Change the fluid every 40,000–60,000 miles – If Recommended

While not all vehicles require power steering fluid replacement, many do benefit from a periodic flush.

Over thousands of miles, the fluid can deteriorate from heat, absorb moisture and carry small particles from internal wear.

As the manufacturer states, changing the fluid every 40,000–60,000 miles protects the seals, keeps the pump lubricated and reduces the risk of clogging or overheating in the system.

4. Don’t turn the wheel at full lock for extended periods of time

Holding the steering wheel at full lock puts maximum pressure on the system.

Holding it in that position for more than a second or two forces the pump to work harder, the fluid temperature rises rapidly and puts more stress on the hoses.

Avoiding excessively long periods of time reduces unnecessary pressure spikes, prevents premature hose wear and keeps the pump operating within a safe load range.

5. Ensure proper belt tension to avoid strain on the pump

The drive belt connected to the power steering pump must be properly tensioned to ensure the pump rotates at the correct speed.

A loose belt can slip, impairing steering assist and overworking the pump, while a too-tight belt can put excessive strain on the pulley bearings.

Checking the belt tension regularly or during service ensures proper pump operation, reducing the load on hoses and other steering components.

Conclusion – How to Repair a Power Steering Hose Leak

Without a doubt, when you take proper steps to repair and maintain your power steering system then you literally adds extra years of life to the pump, hoses and seals, in that way you can save hell lot of money from expensive repairs and unpredictability of steering issues.

A power steering system relies on stable fluid pressure, clean hoses and secure fittings to deliver smooth and predictable steering response.

When a hose begins to leak, the entire system is put under stress, which can lead to hard steering, noisy operation and unnecessary wear on expensive parts like the pump and rack.

By carefully locating the leak, properly removing the damaged hose, installing a new hose with the correct torque and thoroughly bleeding the system, you can restore the fluid flow your steering parts depend on.

This not only restores comfortable, quiet steering but also protects the rest of the system from long-term strain and costly failure.

With regular maintenance—checking fluid levels, inspecting hoses and avoiding pressure-heavy steering habits—you can significantly extend the life of your power steering parts and prevent leaks from returning.

Whether you’re doing the repair yourself or choosing to consult a professional, understanding these steps gives you the knowledge and confidence to make smart decisions and keep your vehicle safe and reliable on the road.

So, that’s all from this guide and if you still have confusion about anything, then just write them down in the comment box.

Frequently Asked Questions

Q1. Why do power steering hoses leak?

Answer: Power steering hoses typically leak because the rubber ages, cracks, or softens from constant exposure to heat and high pressure. Over time, the hose material can break down, causing fluid to leak through small cracks. Vibration can also loosen fittings at the hose ends or wear out metal parts. In some cases, driving habits that create excessive pressure, such as keeping the wheel fully locked for long periods, can accelerate hose wear.

Q2. How do I know if my power steering hose is leaking?

Answer: You can usually tell if a hose is leaking if you see red or pink fluid under your vehicle, hear a noise when turning, or the steering wheel feels stiff or jerky. The power steering reservoir may also be low. Sometimes, if the leak is dripping onto hot engine parts, you may smell burning fluid. Cleaning the area and looking for fresh wet spots can help locate the source.

Q3. Can I drive with a leaking power steering hose?

Answer: Driving with a leaking power steering hose is unsafe because the fluid can suddenly drop, causing serious steering problems. Driving in this condition can damage the pump, overheat the system and cause complete steering failure. Even if the leak seems small, it can quickly turn into a major fluid loss, so it’s always best to have it repaired as soon as possible.

Q4. How much does it cost to fix a power steering hose leak?

Answer: The cost can vary depending on the type of vehicle and the location of the leak. In most cases, replacing the return hose is cheaper because it handles lower pressure and uses a simple clamp. High-pressure hoses are more expensive because they use stronger materials and special fittings. If you do the repair yourself, you’ll mostly have to pay for the hose and fluid. If you go to a mechanic, labor charges will also be added to the cost.

Q5. Is it difficult to fix a power steering hose leak?

Answer: Replacing a power steering hose can be a bit tricky, specially if the hose is in a tight spot or connected to the steering rack in a hard-to-reach place. Many people can do it at home with basic tools, but it requires patience, proper safety precautions and careful bleeding of the system afterward. If the fittings are rusted or the hose is very difficult to reach, consulting a mechanic may be a safer option.

Q6. How long does it take to replace a power steering hose?

Answer: Most repairs take one to three hours, depending on the vehicle’s design. Replacing a simple return hose is usually quicker. High-pressure hoses near the pump or steering rack can take longer because brackets, heat shields, or other parts often need to be removed to access the fittings.

Q7. What type of fluid should I use after replacing a hose?

Answer: You should always use the power steering fluid recommended by your vehicle manufacturer. Using the wrong fluid can affect lubrication, damage the pump, or damage seals. Some vehicles use standard power steering fluid, while others require automatic transmission fluid. This is the safest way to determine which is correct.

Q8. Do I need to bleed the power steering system after replacing a hose?

Answer: Yes, it’s necessary to bleed the system whenever a hose is removed or fluid is drained. Trapped air in the system can cause noise, bubbles, steering stiffness and damage to the pump. Bleeding involves removing this air by turning the steering wheel from lock to lock while the front tires are raised and the fluid level is monitored.

Q9. Why is my power steering still making noise after a hose repair?

Answer: Noise after repair often means that air is still trapped in the system. Continue bleeding the system until the bubbles stop and the fluid becomes clear and stable. If the noise persists, check for loose fittings or other small leaks. Low fluid, worn pump bearings, or a dirty reservoir screen can also cause noise.

Q10. Can a power steering leak damage other car parts?

Answer: Yes, a power steering fluid leak can damage other parts. If fluid drips onto the alternator or belt, it can cause slipping or electrical failure. When the fluid level drops too low, the pump can overheat, leading to complete pump failure. Long-term leaks can also damage metal parts and introduce dirt into the system.

Q11. How can I prevent future power steering hose leaks?

Answer: Regular maintenance helps prevent leaks. Frequently checking the fluid level, inspecting the hoses at every oil change, avoiding long turns at full lock and maintaining proper belt tension all reduce stress on the system. Replacing old fluid when recommended also keeps seals and hoses in good condition.

References:

[1] Safety Recall: 2004–08 TSX Power Steering Feed Hose Leak

https://static.nhtsa.gov/odi/rcl/2010/RCRIT-10V174-1794.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.