Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

The Power Seats actually a standard feature in modern vehicles, as it literally provides both drivers and passengers to adjust their seating according to their comfort with the touch of a button.

Plus, these seats do rely on an electrical system that has switches, wiring, relays and small motors that moves the seat forward, backward, up, down or even you can tilt the backrest as well.

Yes, there can be high chances of any kind of mechanical or electrical component is faulty, yes power seat controls can also be malfunction over the time due to the worn-out motors, blown fuses, faulty switches, loose wiring or any kind of obstructions under the seat also makes them unable to move.

Additionally, it is true that doesn’t matter the reason the non-functioning power seat becomes really frustrating thing and don’t worry about it a lot as most of these kinds of issues are easily repairable.

And this guide is actually about How to Repair Power Seat Controls, so that you can clearly understand how each components work and there’s methods to restore their proper function.

At First, Let’s Understand About Power Seat Systems

Power seats are designed to provide comfort and adjustability, allowing the driver or passenger to move the seat forward, backward, up, down or tilt the backrest with the press of a button.

Modern vehicles use electric power seats that rely on a combination of electrical and mechanical components.

When these components work properly, they provide smooth and precise movement, but when one part malfunctions, the entire seat can stop working or move erratically.

Understanding how the system works is essential to diagnosing and repairing common problems without professional assistance.

1. Components of a Power Seat Control System

A power seat control system has several major components that work together to move the seat.

Switches are the buttons or levers that the driver uses to control the movement of the seat.

Wiring connects the switches to the seat motor and allows electrical signals to flow.

The motor is responsible for physically moving the seat on tracks, whether it’s moving forward, backward, up, down or tilting the backrest.

Fuses protect the system by preventing electrical overloads that could damage the wiring or motor.

Every component needs to be working properly for the seat to operate smoothly and a single faulty part can cause the system to malfunction.

2. In simple terms, here’s how the system works:

When the driver presses the seat control switch, it sends an electrical signal through the wiring to the motor.

The motor then converts this electrical energy into mechanical motion, causing the seat to slide on its tracks or tilt the backrest when needed.

If the system detects too much electrical current, a fuse will blow to prevent damage, interrupting the power supply to the motor until the problem is resolved.

This entire process happens almost instantaneously, making it seem as if the seat is responding immediately to the driver’s command.

By understanding how the switches, wiring, motors and fuses interact, car owners can easily identify problems and make effective repairs.

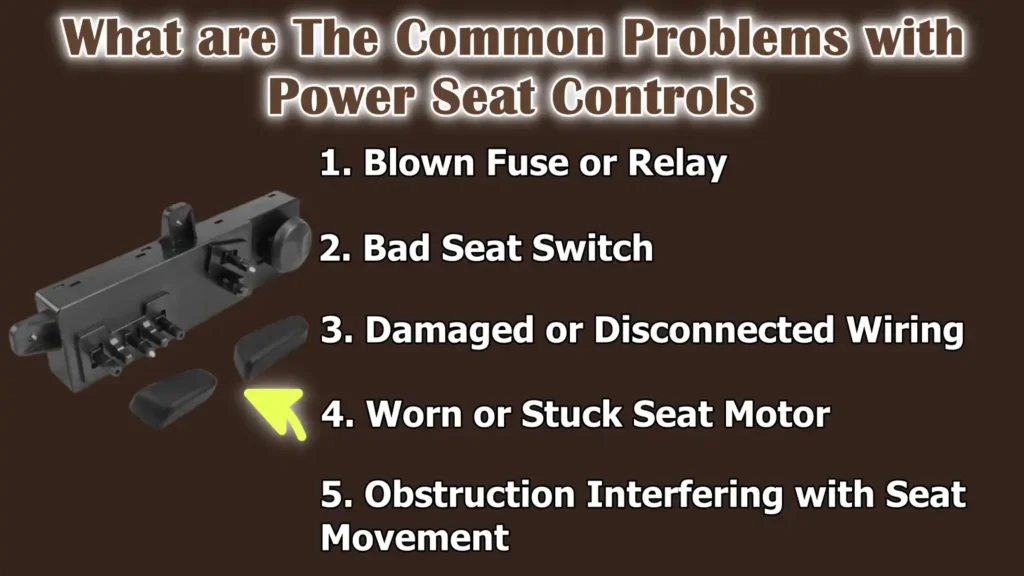

What are The Common Problems with Power Seat Controls

Power seat controls can stop working for several common reasons and understanding these problems can help car owners troubleshoot the problem effectively.

Knowing the potential causes can help identify the problem early and avoid unnecessary replacement or costly repairs.

1. Blown Fuse or Relay

Fuses and relays in a power seat system act as safety devices that protect electrical components from damage.

A blown fuse or a bad relay can completely cut off power to the seat motor, causing the seat to stop working.

This is one of the most common and easily fixable problems, as replacing the fuse or relay usually restores full function almost immediately.

Checking the fuse box and using a multimeter to test the fuse or relay is an essential first step in diagnosing seat control problems.

2. Bad Seat Switch

The seat switch is the button or control that sends commands to the seat motor.

Over time, repeated use can wear out, loosen, or completely damage the switch contacts.

A faulty switch may cause the seat to move intermittently, only in certain directions, or not at all.

Testing the switch with a multimeter or temporarily bypassing it can help determine if the switch itself is the cause of the problem.

3. Damaged or Disconnected Wiring

Wiring connects the switch to the seat motor and provides a pathway for electrical signals.

Wiring can be damaged due to wear, corrosion, or accidental pressure under the seat.

Loose or disconnected wires can disrupt the flow of electricity, causing the seat to malfunction or operate erratically.

These problems can be identified by carefully inspecting the wires and connectors for visible damage or checking for continuity with a multimeter.

4. Worn or Stuck Seat Motor

The seat motor is responsible for moving the seat on its track or adjusting the backrest.

Over time, the motor can wear out, lose power, or become stuck due to mechanical failure or debris inside the motor assembly.

A worn or stuck motor can cause the seat to move slowly, stop mid-movement, or fail completely.

If inspection reveals that the motor is no longer functioning properly, it often becomes necessary to replace it.

5. Obstruction Interfering with Seat Movement

Sometimes, the seat cannot move simply because there is a physical obstruction under or around it.

Objects such as coins, small tools, or debris can block the seat track, hindering smooth movement.

Even a small obstruction can stop or put pressure on the motor, ultimately damaging the system.

Careful inspection and cleaning of the track ensures that the seat can move freely and that unnecessary stress is not placed on the motors and switches.

Tools

| Tools / Materials | Purpose | How it helps in the repair |

|---|---|---|

| Screwdriver | To remove screws holding the seat panel or cover in place. | Allows access to seat components such as switches, motors and wiring. |

| Pliers | To grab, pull or bend wires and connectors. | Helps disconnect or secure wiring without damaging it. |

| Multimeter | To test electrical circuits, fuses and switches. | Accurately identifies faulty wiring, blown fuses or broken switches. |

| Replacement Fuses | To replace blown fuses in the seat’s electrical system. | Restores power to the seat and protects components from overload. |

| Replacement Switch | To replace faulty seat control switch. | Ensures that the seat responds correctly to control commands. |

How to Repair Power Seat Controls – Easy Steps

Repairing power seat controls involves following a systematic approach to identify and resolve the exact cause of the problem.

By carefully checking each component, car owners can restore the seat’s functionality without causing any further damage.

1. Check and replace fuses/relays

The first step is to inspect the fuses and relays that control the seat’s electrical system.

Fuses protect the system by preventing excess current from damaging the wires or motors, while relays act as switches to control the electrical flow.

A blown fuse or bad relay causes the power supply to the motor to be cut off, causing the seat to not move.

Locate the seat fuse in the vehicle’s fuse box, remove it and check if it is blown.

If necessary, replace the fuse or relay with a matching fuse or relay.

After replacement, check the seat to see if it is working.

2. Check for wear or damage to the seat switch

Next, check for signs of wear, loose connections or physical damage to the seat control switch.

The switch is the interface that sends signals to the motor to move the seat.

A damaged or worn switch can cause the seat to move intermittently or stop working altogether.

Carefully remove the switch from the seat panel, check the wiring connections and test its functionality with a multimeter.

If the switch does not transmit power correctly or shows signs of malfunction, replace it.

3. Check the wiring connections with a multimeter

Wiring is critical for sending electrical signals from the switch to the motor.

Over time, wires can become loose, frayed or detached, causing the seat to not function properly.

Use a multimeter to check the continuity of the wires, making sure electricity is flowing from the fuse and switch to the motor.

Check for corrosion or damage to the connectors and repair or replace any frayed wiring.

Properly secured and intact wiring is essential to restoring full seat operation.

4. Check motor operation and replace if defective

The seat’s motor is responsible for physically moving the seat on its tracks.

If the motor is worn, stuck, or defective, the seat may move slowly, stop midway, or not move at all.

Apply direct power to the motor using a switch or test source and see if it is working.

If the motor is not working properly, it should be removed and replaced with a new or working replacement motor.

Proper operation of the motor ensures smooth seat movement in all directions.

5. Remove any obstructions or debris beneath the seat

Physical obstructions beneath the seat may interfere with smooth movement or put pressure on the motor and tracks.

Carefully inspect the seat area for coins, small tools, or debris blocking the tracks.

Remove any obstructions to allow the seat to move freely.

Cleaning the area also reduces the risk of damaging the motor or switch while operating the seat.

6. Reassemble the seat and check its functionality

After all parts have been checked, repaired or replaced, reassemble the seat panel and make sure all screws and connectors are securely in place.

Test the seat by moving it in all directions using the seat switch.

Make sure the seat is operating smoothly and consistently.

If the seat is operating correctly, the repair is complete.

If the problem persists, double-check each step to identify any overlooked problems.

How to Prevent It and Maintain Power Seat Controls

Properly maintaining your power seat system can extend its life and prevent costly repairs.

Regular preventive care ensures that all parts work smoothly and reduce the likelihood of sudden malfunctions.

1. Clean under the seat regularly to avoid blockages

Dirt, dust and small objects can accumulate under the seat and block the seat track, causing strain on the motor or stopping its movement altogether.

Regularly inspecting and cleaning the area under the seat removes potential blockages and keeps the seat moving smoothly.

Using a simple vacuum cleaner or soft cloth to clean the track and surrounding areas prevents mechanical stress and reduces wear on the motor and switches.

2. Check the wiring and connectors during routine maintenance

Electrical problems are one of the most common causes of power seat malfunctions.

Periodically checking wires and connectors ensures that all electrical connections remain strong, corrosion-free and properly insulated.

Loose or damaged wires can disrupt the flow of electricity to the motor, while corroded connectors can impede seat movement.

Regular inspections can spot problems early, allowing minor repairs to be made before they become a major problem.

3. Avoid Overloading the Seat Mechanism

Each power seat is designed to withstand a certain weight and force.

Putting excessive pressure on the seat mechanism, applying excessive loads, or forcing it to move beyond its normal limits can damage the motor, tracks and switches.

Careful use of the seat and avoiding sudden or excessive pressure maintains the integrity of the components and ensures long-term smooth operation.

Read More:

When You Should Go to the Repair Shop

Although many power seat problems can be fixed at home with careful inspection and basic tools, professional assistance is the safest and most effective option in some situations.

Knowing when to seek expert help can prevent further damage, save time and ensure your seat continues to operate safely and reliably.

Not only this, study shows that there’s mechanical wear inside the seat gearbox and motor that actually causes seats to be stuck or becomes slow in movement, as whenever the electrical checks pass and there’s not fault in it then you have to remove and inspect the motor gearbox if there’s worn gears, excess grease breakdown or metal shavings available before deciding to replace the entire motor.[¹]

1. If Replacing the Motor Is Too Complicated

Replacing a power seat motor can sometimes be complicated, specially in modern vehicles where the seat electronics or motor are integrated into the seat frame.

If the motor is difficult to access, is connected to multiple sensors, or requires disassembling sensitive components, it is safer to have it replaced by a professional.

Attempting to replace a complex motor without proper knowledge could result in electrical damage or improper seat operation.

2. If the Seat Track Alignment Is Damaged

Seat tracks guide the seat’s movement and misalignment or damage can hinder smooth operation or even cause the seat to become stuck.

Realigning or repairing a damaged track requires precise adjustments to ensure the seat moves evenly and safely.

Professionals have the tools and expertise to correct alignment issues without compromising the seat mechanism or motor.

3. When electrical troubleshooting becomes too complex

Power seat systems contain switches, wiring, relays and motors that must work together properly.

If electrical troubleshooting requires advanced testing, such as diagnosing complex wiring faults, short circuits, or sensor problems, it’s advisable to seek professional help.

Experts can quickly identify and repair electrical problems, ensuring safety and preventing further damage to the vehicle’s electrical system.

Conclusion – How to Repair Power Seat Controls

A seat should be smooth and adjustable and to make this possible it is really important to keep the motors, switches and wiring working perfectly together and that’s why you should understand more about this system that gives you control of your own repairs.

Power seats rely on a coordinated system of switches, wiring, fuses, relays and motors and a malfunction in any one component can cause the seat to stop or operate erratically.

By carefully inspecting each component, checking electrical connections, removing obstructions and replacing worn parts, you can restore your seat’s full functionality without spending a fortune on a mechanic’s fees.

Regular preventative maintenance, such as cleaning under the seat, checking wiring and avoiding overloading the seat, ensures your power seat runs smoothly for years.

However, certain situations, such as complex motor replacements, damaged seat tracks, or serious electrical problems, are best handled by professionals to ensure safety and prevent further damage.

By following these guidelines, you can enjoy a comfortable and fully functional seat while increasing your confidence in the maintenance of your vehicle’s systems.

Now, it is time to ask the questions with the help of comment section.

Frequently Asked Questions

Q1. What causes a power seat to stop working?

Answer: A power seat may stop working due to several common problems. One of the most common problems is a blown fuse or bad relay that cuts power to the seat motor. Other causes include a worn or broken seat switch, damaged or disconnected wiring, a stuck or bad motor, or a physical obstruction under the seat that prevents movement. Understanding these causes helps to quickly locate the problem and make an effective repair.

Q2. How can I check if my power seat fuse is blown?

Answer: To check if a fuse is blown, first find the fuse box in your vehicle, usually located under the dashboard or in the engine compartment. Remove the fuse that controls the power seat and check it. A blown fuse usually has a broken metal strip inside or appears black. For more accuracy, you can use a multimeter to check for continuity. If a fuse blows, replacing it with one of the same rating can often restore your seat’s function immediately.

Q3. How do I know if my seat switch is bad?

Answer: A bad seat switch can cause the seat to move irregularly, only in certain directions, or not at all. You can test whether the switch is sending electrical signals correctly by pressing the switch in every direction and listening to the motor’s response, or by using a multimeter. If the switch does not transmit power or shows no continuity, it must be replaced for the seat to function properly.

Q4. Can I fix a stuck or bad seat motor myself?

Answer: In some cases, the car owner can replace the seat motor with basic tools and careful guidance, specially if they are readily available. However, in modern vehicles, the motor may be integrated with sensors or seat electronics, making replacement more complicated. If the motor is difficult to reach or is connected to sensitive wiring, it is safer to have a professional perform the replacement to avoid damage or safety issues.

Q5. How can I prevent future power seat problems?

Answer: Preventive care can greatly reduce the risk of a seat failure. Regular cleaning underneath the seat removes dirt, debris and small objects that may be blocking the track. Checking the wires and connectors during routine maintenance ensures that electrical connections remain secure and corrosion-free. Putting excessive weight on the seat or pushing it beyond normal limits also prevents mechanical stress on the motor and track. Following these steps will ensure smooth seat operation for years to come.

References:

[1] Development and performance analysis of an automotive power seat for disabled persons

https://www.researchgate.net/publication/226376369_Development_and_performance_analysis_of_an_automotive_power_seat_for_disabled_persons

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.