Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

The reason for felling vehicle in a loose way or vehicle is making strange clunking sound when you turn them, then the worn out sway bar links could be affecting factor actually they works tirelessly to maintain stability and smoothness until they wear out.

Even, these links literally connects the sway bar which is also known as the stabilizer bar to your suspension system, which is why it helps to reduce body roll when you take turns or drive over the uneven surfaces.

But over the period of time, these links can also wear out due to the constant movement, exposure to the water, salt and of course road debris as well.

So, whenever they wear out, then simply your car may start producing that annoying clunking noises, you can feel unstable while cornering or even it shows your signs of uneven tire wear as an indicator as well.

Plus, according to automotive maintenance data from industry reports, the worn sway bar links are actually among the top 5 most common causes of poor vehicle handling and suspension noise in passenger cars as well.

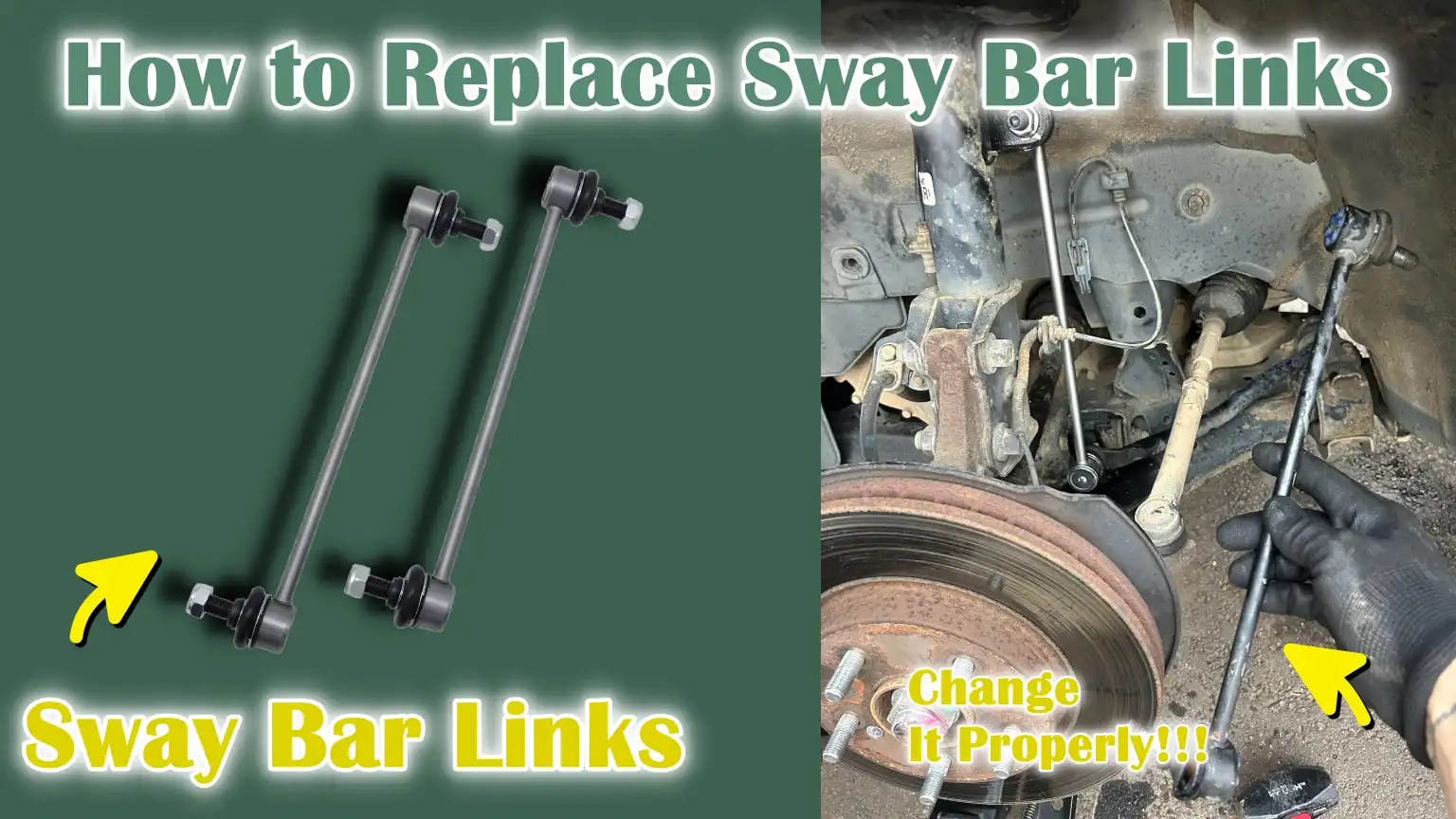

But the great thing is that you can also learn How to Replace Sway Bar Links, so that you can fix that problem with few basic tools to extends the lifespan of your suspension system.

At First, You Should Understand Sway Bar Links

1. Function – How Sway Bar Links Connect the Stabilizer Bar to the Suspension

The sway bar link is a crucial connector between the stabilizer bar, also known as the anti-roll bar and the vehicle’s suspension system.

Its main function is to transfer force from one side of the suspension to the other when driving on turns or uneven surfaces.

When your car turns, one part of the suspension compresses while the other part extends.

The sway bar, through its links, resists this motion and keeps the vehicle’s body level.

This simple mechanism helps reduce body roll, improve stability and increase tire contact with the road for better grip and safety.

In everyday driving, this means better handling and more predictable steering response, specially during sudden turns or when driving at high speeds.

2. Location – Front and Rear Sway Bar Link Locations

Sway bar links are found in both the front and rear suspension systems of most vehicles.

Depending on the vehicle’s design, the front sway bar links connect the stabilizer bars to the control arms or struts and are primarily responsible for controlling body roll during steering.

Rear sway bar links are often shorter and maintain stability when the vehicle is rocking side to side or under heavy loads.

The front links typically bear more stress due to steering and engine loads, while the rear links help maintain balance and comfort for passengers.

Some vehicles, particularly performance or off-road models, have adjustable sway bar links that allow for fine adjustments according to handling preferences.

Knowing the location of these links is helpful when properly inspecting or replacing them.

3. Types – Conventional vs Ball-Joint Style Sway Bar Links

Sway bar links come in various designs, primarily traditional bushing-style and ball-joint-style links.

Conventional sway bar links typically have rubber or polyurethane bushings at both ends, which dampen motion and absorb vibration.

These are simple and economical, but can wear out quickly under harsh conditions.

On the other hand, ball-joint-style sway bar links use smaller ball-and-socket joints that provide smoother engagement and a wider range of motion.

They are more durable and better suited for modern vehicles requiring precise suspension control.

High-performance and newer models often use ball-joint links because they provide more robust handling and last longer than traditional designs.

Choosing the right type depends on your vehicle’s suspension layout, driving habits and comfort preferences.

4. Common causes of wear – rust, worn bushings, poor driving conditions

Sway bar links are constantly exposed to the movement of the suspension, so they experience significant wear over time.

One of the most common causes of wear is rust, specially on cold roads in winter or in areas with high humidity.

Moisture and dirt can enter the joints or bushings, causing rust and stiffness.

Worn bushings are another common problem, as the rubber or polyurethane material gradually deteriorates due to heat, pressure and age.

Rough or unpaved roads exacerbate this wear, causing the link ends to loosen or break.

Once damaged, the sway bar links cannot effectively transfer force, resulting in rattling noises, decreased cornering stability and reduced ride comfort.

Regular inspection and timely replacement are the best ways to prevent these problems and maintain safe, responsive operation.

Common Symptoms of a Bad Sway Bar Link

1. Clunking or Rattling Sounds When Driving Over Bumps

One of the most common and easily recognizable symptoms of a bad sway bar link is a rattling or rattling sound coming from underneath the vehicle when driving over rough or uneven roads.

This sound occurs because the worn or broken link no longer holds the stabilizer bar firmly in place.

When the suspension moves up and down, the loose connection allows the sway bar to hit surrounding components, producing a metallic or slightly rumbling sound.

This sound often intensifies when driving slowly over uneven surfaces or speed bumps.

In severe cases, this sound may be heard even with slight steering movements.

As this symptom can mimic sounds coming from other suspension parts, such as ball joints or control arm bushings, directly inspecting the sway bar link is the best way to confirm the problem.

2. Poor Handling or Excessive Body Roll During Turns

Faulty sway bar links can also impair your vehicle’s handling, specially when cornering.

When the links wear out or break, the sway bar loses its ability to control side-to-side body movement.

As a result, the car leans more than normal during turns, causing a feeling of instability or unsteadiness.

Drivers may experience reduced steering response and the car takes longer to return to its normal position after a turn.

This excessive body roll not only reduces comfort but also increases the risk of losing grip in emergency situations.

Properly functioning sway bar links are essential for ensuring that both tires remain in good contact with the road during turns, ensuring balanced handling and better control.

3. Uneven Tire Wear or Instability on Rough Roads

Faulty sway bar links can indirectly cause uneven tire wear and instability when driving on rough or uneven roads.

Because links help maintain even pressure on the suspension, damaged links disrupt the suspension’s balance, causing one side of the vehicle to bear more weight than the other.

Over time, this imbalance causes irregular tire wear patterns, such as wear on the inner or outer edge.

Furthermore, the vehicle may feel unstable or tilt when driving over potholes or uneven roads.

This is because the sway bar can no longer distribute the weight evenly on both sides of the vehicle.

If this problem is not addressed, it not only affects tire life but can also put stress on other suspension components, such as struts and bushings.

4. Looseness or Damage on Inspection

Another obvious sign of a bad sway bar link is looseness, rust, or damage to the suspension.

A healthy sway bar link should be strong and securely connected at both ends.

If the link appears bent, the bushing is cracked, or the ball joint is overstretched, it means the link is worn and needs to be replaced.

In many cases, the rubber bushing may be worn and allowing excessive movement, or the metal rods may show signs of rust and wear.

When inspecting sway bar links, try wiggling them by hand; any noticeable stretching or movement usually indicates a problem.

Regular inspections during oil changes or tire rotations can help catch early signs of wear before they affect your vehicle’s handling and safety.

Tools

| Tool / Material Name | Purpose / What It Does | Why It’s Important |

|---|---|---|

| Jack and Jack Stands | The jack raises your car off the ground and jack stands keep it securely in place while you work underneath. | These keep your car stable and prevent it from falling over while removing and replacing parts. Safety always comes first. |

| Lug Wrench or Impact Wrench | A lug wrench helps loosen and tighten the nuts that hold your wheel in place. An impact wrench makes this job faster. | Accessing the sway bar links requires you to remove the wheel and this tool helps you do that easily and safely. |

| Ratchet Set and Sockets | This tool is used to remove and tighten bolts and nuts on sway bar links and suspension parts. | It gives you the right grip and power to loosen tight bolts without damaging them. |

| Penetrating Oil (e.g., WD-40) | A special spray that penetrates deep into threads to loosen rusted or stuck bolts. | Many sway bar link bolts rust over time and this oil helps you remove them without breaking or stripping the bolts. |

| Torque Wrench | A torque wrench measures the tightness of a bolt as you tighten it. This helps you tighten the bolt to the correct torque specified by the manufacturer. | This ensures that the sway bar link bolts are not too loose or too tight, keeping your suspension safe and properly balanced. |

| Replacement Sway Bar Links (OEM or Aftermarket) | These new parts replace your old, worn-out sway bar links. OEM stands for “Original Equipment Manufacturer,” meaning factory-made parts. | New sway bar links improve your car’s handling, balance and ride comfort. Choosing high-quality parts ensures they last a long time. |

| Safety Gloves and Goggles | Gloves protect your hands from sharp edges, dirt and chemicals, while goggles protect your eyes from dust and debris. | These are essential for personal safety when working under your car or using sprays and tools. |

How to Prepare Before Replacing Sway Bar Links

1. Park on a Level Surface and Apply the Parking Brake

Before replacing your sway bar links, the most important step is to ensure your vehicle is parked on a completely level and stable surface.

Level ground prevents the vehicle from rolling or swaying while working underneath.

Always set the gear to “Park” if the vehicle has an automatic transmission, or “First” gear if the vehicle has a manual transmission.

Then, firmly engage the parking brake to keep the vehicle stable.

This step may seem simple, but it’s an essential safety precaution.

Working on uneven or sloping ground can be very dangerous, as even the slightest shift in balance can cause the vehicle to suddenly sway.

You can also place wheel chocks or heavy blocks on the ground behind the tires for added safety.

Taking a little time to properly secure your vehicle ensures a safe and reliable start to the replacement process.

2. Loosen the wheel lug nuts slightly before lifting

Once the vehicle is secure, the next step is to loosen the wheel lug nuts slightly before lifting it off the ground.

Doing this while the tire is touching the ground prevents the wheel from spinning when turning the wrench.

You don’t need to remove the nuts completely at this stage; just loosen them enough so they can be easily unscrewed later.

Depending on your equipment, a lug wrench or impact wrench can be used for this step.

This step also helps you determine if any lug nuts are overtightened or rusted.

Loosening them beforehand can prevent problems after lifting the car, as trying to loosen a tight bolt while the wheel is hanging can cause the car to shake and become unstable.

This small but important step helps ensure a smooth and safe repair process.

3. Raise the vehicle safely with a jack and support it with jack stands

After loosening the lug nuts, carefully raise the vehicle using a hydraulic or scissor jack.

Always consult your vehicle’s manual to locate the correct jacking points, which are usually sturdy metal parts near the wheels.

Never lift the car from any random spot under the body, as this could damage or destabilize the car.

Once the vehicle is raised high enough for you to work comfortably, place jack stands under the frame or suspension mounting points to support the vehicle’s weight.

Lower the jack slowly so that the car is firmly resting on the stands.

Don’t rely solely on the jack to raise the car, as hydraulic pressure may suddenly decrease.

Before working underneath, gently rock the vehicle to double-check its stability.

Proper lifting and support are essential for safe and effective automotive repair work.

4. Remove the wheel for better access to the sway bar links

Once the car is securely in place, you can completely remove the loosened lug nuts and remove the wheel.

Removing the wheel opens up the work area, giving you easier access to the sway bar links and other suspension parts.

Place the removed wheel upright on the ground near your work area; this can also serve as an additional safety barrier in case of an accident.

After removing the wheel, take a moment to inspect the surrounding suspension components, such as the control arm, strut and bushing.

This will help you identify any other worn or damaged parts that may need attention.

Having a clean, open space to work in makes it easier to remove the old sway bar links and install the new ones correctly, making the job safe and efficient.

How to Replace Sway Bar Links – Full Process

1. Locate the sway bar links connected to the stabilizer bar and control arm or strut

Begin the replacement process by carefully installing the sway bar links on your vehicle.

These links are usually short metal rods, positioned vertically or at a slight angle and connect the sway bar to the control arm or strut assembly.

You’ll find one link on either side of the suspension, front or rear, depending on your vehicle’s design.

Take some time to identify the points where the link is attached, as this will help you understand how the new link should be installed later.

It’s also helpful to compare the links on both sides of the car to ensure the link you’re replacing matches in size and mounting style.

Understanding this setup in advance makes removal and installation easier and can prevent mistakes during alignment.

2. Apply penetrating oil to loosen rusted bolts and nuts

Before attempting to remove any bolts or nuts, it’s wise to spray penetrating oil, such as WD-40, on the threaded parts of the sway bar links.

These parts are often exposed to moisture, dirt and salt from the road, which can cause rust and make them very tight.

Let the oil soak in for at least five to ten minutes so it can penetrate the threads and break down the rust.

This simple step can save you a lot of trouble and prevent bolts from breaking due to excessive force.

If the links are heavily rusted, applying a second coat of oil and lightly tapping the bolts with a wrench can help loosen them further.

This extra precaution makes the job safer and ensures a smooth removal process.

3. Remove the old sway bar links using a suitable socket or wrench

Once the bolts are thoroughly lubricated, begin removing the old sway bar links.

To ensure the bolts are properly seated, use the correct socket or wrench, as using the wrong tool can strip the heads.

Some sway bar links have a stud with an internal hex or Torx fitting, which prevents the bolt from rotating while loosening the nut.

If so, insert a matching hex key or Torx bit to hold the stud in place while turning the nut with a wrench.

Work slowly and apply steady pressure rather than sudden force.

When both ends of the link are loose, remove the part completely and set it aside.

If the bushing is bent, broken, or worn, this confirms that it needs to be replaced.

4. Inspect surrounding components, such as the sway bar bushing and control arm

After removing the old link, take a few minutes to inspect the surrounding suspension components.

Check the sway bar bushing for cracks, dryness, or looseness.

Check for wear or damage to the control arms, strut mounts and ball joints.

All of these components work together to maintain stability with the sway bar, so any weakness in them can reduce handling quality even after installing new links.

Cleaning the area with a cloth or brush also helps remove dirt or debris that could interfere with proper installation.

This inspection step ensures that your new sway bar links will function efficiently and won’t be affected by hidden suspension problems.

5. Install the new sway bar links by properly aligning them and threading the bolts by hand

Next, install the new sway bar links in the same locations where the old links were removed.

Align the ends with the holes in the sway bar and control arm or strut mount.

Thread the bolts by hand before using any tools.

Hand-threading ensures the bolts are straight and prevents thread damage.

Once both ends are loosely in place, check that the links are straight and evenly spaced between the mounting points.

Correct alignment is essential because bent or angled links can cause premature wear or noise later.

After confirming alignment, you can begin tightening the bolts with your ratchet or wrench.

6. Tighten the bolts according to the manufacturer’s torque specifications using a torque wrench

After installing the sway bar links, use a torque wrench to tighten each bolt according to your vehicle manufacturer’s instructions.

These torque values are usually provided in the service manual or sometimes printed on the parts packaging.

Tightening the bolts too loosely can cause noise and rattling, while overtightening can damage the threads or bushings.

A torque wrench ensures you apply the correct amount of pressure for a secure and durable fit.

When tightening, check that the sway bar and suspension move freely without any obstruction.

This precise step helps your new sway bar links function properly and last for many miles.

7. If necessary, repeat the same process on the other side

Most vehicles have sway bar links on both sides of the suspension and it’s usually recommended to replace them in pairs.

This is because if one link fails, the other is almost certain to fail as well, as both have experienced similar driving conditions and stress levels.

From link diagnosis to repair, take these precautions at all times.

Read More:

Basic Post-Replacement Steps

1. Reinstall the Wheel and Tighten the Lug Nuts

Once the new sway bar links are securely installed, the next step is to reinstall the wheel.

Carefully place the wheel back on the hub, ensuring it aligns properly with the lug holes.

Begin tightening the lug nuts by hand to avoid cross-threading, as this can damage both the nuts and the wheel studs.

After all the nuts are hand-tightened, use a lug wrench or impact wrench to tighten them in a crisscross pattern.

This even tightening pattern helps keep the wheel flat on the hub and prevents vibration during driving.

At this point, do not fully tighten the lug nuts yet as the car is still elevated; the final torque should be applied after the vehicle is lowered to the ground.

Being careful during this step ensures a smooth and balanced wheel fit, which directly affects ride comfort and safety.

2. Lower the Vehicle

After reinstalling the wheels and tightening the lug nuts, it’s time to lower the vehicle.

Use a jack to lift the car off the jack stands and slowly raise it slightly.

Remove the stands one by one, being careful not to move the car.

Once the stands are clear, slowly lower the car to the ground until all four tires are firmly and evenly seated.

To avoid sudden weight changes that could affect suspension components, it’s important to lower the vehicle slowly.

Once the lug nuts are securely in place, use a torque wrench to fully tighten the lug nuts to the manufacturer’s specified torque level.

Properly tightening the lug nuts after lowering the vehicle ensures the wheels are securely in place and prevents any movement that could cause vibration or imbalance during driving.

3. Test drive to ensure there are no noise or handling issues

After completing the installation, take your vehicle for a short and careful test drive to ensure everything looks and sounds right.

Drive slowly at first, specially over small bumps or turns and pay attention to any unusual rattles or rattles that could indicate a loose connection.

As you accelerate, pay attention to the steering—properly fitted sway bar links will make the vehicle feel stable and balanced in turns.

The body shouldn’t lean excessively and the suspension should operate smoothly even on uneven road surfaces.

If you previously experienced loud rattles or poor handling, these symptoms should have disappeared by now.

A good test drive not only confirms that the work was done correctly but also helps give you confidence in your repair.

4. Check for looseness or re-torque bolts after a short drive

After completing a test drive, it’s a good practice to double-check your work.

Park the vehicle again on level ground, apply the parking brake and inspect the sway bar links.

Ensure there are no signs of movement, gaps, or misalignment at the connection points.

Using a torque wrench, check that all bolts and nuts are still tightened to the correct specifications.

It’s common for new parts to settle slightly after the first few miles, so this recheck is important.

Also, make sure the lug nuts on the wheels are properly torqued.

Taking this extra step ensures long-term reliability, prevents unwanted noise later and keeps your suspension system functioning smoothly.

A quick follow-up inspection helps ensure that your repair is solid and your car is safe for continued use.

Common Mistakes to Avoid on Replacing Sway Bar Links

Yes, when you replace sway bar links then it simply restores the connection between the stabilizer bar and suspension, but you actually have to know the bar itself should be tuned for the vehicle weight and handling as well. Because design studies actually shows that roll stiffness can changes with bar size and arm length as well, so whenever you fit new sway bar links then you have to make sure they matches the bar and vehicle completely: otherwise mismatched parts can change handling badly as well.[¹]

1. Not Using a Torque Wrench to Properly Tighten Bolts

One of the most common mistakes people make when replacing sway bar links is not using a torque wrench to properly tighten the bolts.

Each bolt in a vehicle’s suspension system is designed to be tightened to a specific torque value specified by the manufacturer.

This ensures that the connection is neither too loose nor too tight.

When bolts are undertightened, vibration can cause them to gradually loosen, causing a rattling noise while driving or even causing the sway bar link to separate completely.

On the other hand, overtightening can stretch or strip the threads and damage the bushing or ball joint, reducing the lifespan of the new link.

A torque wrench provides the correct level of tightening, preventing mechanical stress and ensuring that the suspension system remains safe and balanced.

Taking extra time to properly torque the bolts is one of the easiest ways to ensure a safe and lasting repair.

2. Forgetting to Apply Penetrating Oil Before Removing Bolts

Another common mistake during the bolt replacement process is not using penetrating oil before loosening the bolts.

Over time, sway bar links are exposed to moisture, dirt and road salt, which can lead to rust and make bolt removal extremely difficult.

Trying to loosen rusted bolts without lubrication often results in bolts breaking, stripping threads, or tool damage.

Applying penetrating oil, such as WD-40, a few minutes before removing the bolts allows the liquid to seep into the threads, breaking down the rust and loosening the bolts.

This not only makes the job easier but also prevents unnecessary damage to suspension components.

Proper preparation with penetrating oil saves time, effort and money, as well as reduces hassle during the repair process.

3. Replacing Only One Sway Bar Link Instead of Both

Many vehicle owners make the mistake of replacing only one sway bar link, even if both links are worn to the same extent.

As the left and right links work together to stabilize the vehicle, replacing just one link can cause an imbalance in suspension performance.

The new link will have a stiff and responsive joint, while the old link will still be loose and stressed, resulting in uneven handling or persistent noise.

For this reason, professional mechanics always recommend replacing sway bar links in pairs.

This ensures that both sides of the suspension respond equally to motion, resulting in smoother cornering, better stability and more consistent performance.

This approach also saves time in the long run because it prevents the need to repeat the same work if the second link fails.

4. Ignoring Damaged Bushings or Mounts

Another common mistake is not inspecting and addressing other worn suspension components when replacing sway bar links.

Sway bar links work in conjunction with the sway bar bushings, control arms and strut mounts to maintain vehicle stability.

If these surrounding components are damaged or worn, simply installing new sway bar links won’t completely resolve handling or noise issues.

For example, a broken sway bar bushing can cause the bar to move excessively, resulting in a rattling sound even after installing new links.

Similarly, weak strut mounts can put uneven pressure on the suspension, affecting performance.

Taking a few extra minutes to inspect and replace any worn parts during the same repair session ensures the entire system is functioning properly.

Neglecting these components often leads to recurring problems, additional labor and unnecessary costs in the future.

When to Go for Professional Help

1. Bolts Are Rusted or Seized and Difficult to Remove

One of the most challenging problems when replacing sway bar links is rusted or completely seized bolts.

Over time, exposure to rain, road salt and moisture corrodes the threads, making loosening the bolts extremely difficult.

Applying penetrating oil may help in mild cases, but when corrosion is severe, even strong tools or impact wrenches may not be effective.

Applying too much force to the bolts can cause them to break, leaving some metal trapped inside the suspension component, making repair difficult without the proper tools.

Professional mechanics have specialized tools such as heat torches, bolt extractors and pneumatic impact guns that can safely remove seized fasteners without damaging surrounding parts.

If you’re having trouble turning the bolts despite repeated attempts, it’s safer and more effective to have a professional do the work rather than risk breaking the parts or injuring yourself.

2. Suspension Components Appear Damaged

If you inspect your sway bar links and other suspension components, such as sway bar bushings, control arms, struts, or ball joints and find that they are worn, broken, or bent, it’s best to seek professional help.

These components work together to maintain your vehicle’s stability and steering performance and damage to any one of them can affect the operation of the entire suspension system.

A mechanic can perform a thorough inspection using professional diagnostic equipment to determine whether the damage is minor or part of a larger problem, such as frame misalignment or uneven tire wear.

In some cases, simply replacing the sway bar links won’t solve the problem, specially if the damage extends deeper into the suspension system.

Attempting to replace parts like control arms or struts without the proper tools and experience can lead to incorrect installation or unsafe driving conditions.

Professional technicians can ensure that each part is repaired or replaced correctly to restore your vehicle’s full safety and comfort.

3. Lack of tools or experience for safe lifting and repair

Replacing sway bar links is often considered a simple repair that can be done at home, but it requires proper tools, safety equipment and mechanical understanding.

Without a reliable floor jack, sturdy jack stands, or a torque wrench, this repair can be risky.

Working under a car without proper support can be extremely dangerous, as jacks can suddenly malfunction or move.

Additionally, some mechanical knowledge is required to correctly identify torque specifications, alignment points and suspension geometry.

A small mistake, such as tightening a bolt at the wrong angle or cross-threading a nut, can lead to poor handling, noise, or premature wear of the new parts.

Professional mechanics not only have the right tools but also the experience to perform repairs efficiently and safely.

If you’re unsure about any part of the process—from lifting the car to tightening bolts—it’s always best to take the vehicle to a reputable repair shop.

The cost of professional assistance is often much less than the potential cost of repairing a defect later or replacing suspension parts damaged due to improper installation.

Conclusion – How to Replace Sway Bar Links

So, now you have clearly understood the importance of sway bar links as they actually keeps the car balanced and controlled on the road.

While these seemingly insignificant components may seem trivial, they play a crucial role in keeping your vehicle stable during turns and your tires firmly planted on the road.

Properly functioning sway bar links ensure the suspension system performs as expected, reducing body roll, improving steering response and providing a more comfortable driving experience.

When the links wear out, even normal everyday driving can become unstable, noisy and less predictable, so replacing them immediately is essential.

By following the correct steps—properly preparing the vehicle, using the right tools and tightening the bolts according to the manufacturer’s instructions—you can confidently restore your suspension’s performance and driving comfort.

It’s also important to inspect surrounding components, such as bushings and control arms, when replacing them, as these areas often show wear at the same time.

Replacing both sway bar links in pairs and checking for any residual noise after installation ensures long-term stability and reliability.

For many drivers, this repair is possible with patience and the right tools.

However, if the bolts are severely rusted or you don’t have the right equipment for safe lifting and torque accuracy, seeking professional assistance is the best option.

Mechanics can identify any hidden suspension damage, confirm correct alignment and ensure the repair is completed safely.

Ultimately, maintaining your sway bar links not only extends the life of your suspension but also restores confidence in your vehicle’s handling—specially during sharp turns, rough roads, or sudden lane changes.

Now, you can comment down below for more information.

Frequently Asked Questions

Q1. What does a sway bar link do in a car?

Answer: The sway bar link, also called a stabilizer bar, connects the vehicle’s suspension components, such as control arms or struts. Its job is to help control body movement when the car turns or drives on uneven surfaces. Without it, your car would lean excessively when cornering, leading to unstable handling. The sway bar link transfers force to both sides of the suspension, keeping the car balanced and improving traction. When it’s in good condition, you can enjoy smoother turns, better steering control and safer driving at all speeds.

Q2. How do I know if my sway bar links are bad?

Answer: The most common sign of a bad sway bar link is a rattling or scratching sound when driving on rough or uneven roads. You may also notice the car swaying excessively when turning, or it may feel unstable when changing lanes. Sometimes, uneven tire wear or poor cornering handling can also indicate worn links. During a visual inspection, if you notice cracks in the rubber bushing, corrosion, or looseness at the link’s attachment point, these are clear signs that it needs to be replaced.

Q3. Can I drive with a bad sway bar link?

Answer: Although it’s possible to drive with a worn or broken sway bar link, it’s not recommended to use it long-term. A damaged link weakens your suspension’s stability, specially during turns or sudden bends. This means your car may roll or tilt excessively, increasing the risk of losing control in an emergency. Driving without addressing the problem can also cause excessive wear on tires and other suspension components. If you hear any noises or notice handling problems, it’s best to replace the link as soon as possible to keep your vehicle safe.

Q4. How long do sway bar links typically last?

Answer: On average, sway bar links can last 50,000 to 100,000 miles, but this depends on your driving conditions and the quality of the parts. Cars driven on smooth highways typically have longer links, while vehicles driven in potholes, rough roads and inclement weather can wear out faster. Regular inspection during routine maintenance can detect wear early, before it becomes a major problem. Using high-quality OEM or high-grade aftermarket parts ensures that the links last longer and perform more consistently.

Q5. Do sway bar links affect alignment?

Answer: Sway bar links themselves do not directly affect wheel alignment because they are part of the suspension’s stabilization system rather than the steering geometry. However, if a link is excessively worn or broken, it can affect the suspension’s movement, leading to uneven tire wear or poor handling. After replacing the sway bar links, it’s a good idea to have the alignment checked by a professional, specially if you also replaced control arms, bushings, or other suspension components at the same time.

Q6. How difficult is it to replace sway bar links at home?

Answer: Replacing sway bar links is considered a simple repair. If you have basic mechanical skills, the right tools and safety equipment, it’s a simple task. It usually involves jacking up the car, removing the wheel, loosening the old links and installing new links to the required torque. However, rusted bolts can complicate the job and improper installation can increase noise or cause handling problems. If you’re unsure about your tools or experience, seeking professional help is a safer option.

Q7. Do I need to replace both sway bar links at once?

Answer: Yes, it’s highly recommended to replace both sway bar links on the same axle, even if only one is damaged. Because road conditions and wear are similar on both sides, other links are also likely to wear out. Replacing these links in pairs ensures balanced suspension performance and prevents uneven handling or noise from returning immediately after repair. This is why mechanics often replace shock absorbers, struts, or brakes in pairs for consistent performance.

References:

[1] Design, Analysis and Optimization of Anti-Roll Bar

https://www.ijera.com/papers/Vol4_issue9/Version%204/T4904137140.pdf

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.