Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Actually squeaky brakes are really one of the most commonly found problems but they are very annoying as well.

Yes, they are totally harmless but it is actually warning sign that something in your braking system needs a serious attention.

As well as, brake squeaking can be the reason behind the worn out brake pads, dirt or rust can be available on the rotors, also if there’s poor lubrication.

Along with this, in some of the cases it is just the result of the morning moisture as well, but if the sound doesn’t actually go away after a few stops then it is time to investigate what’s behind it.

So, in this guide you’ll understand that how brakes really works and what causes that squeaky sound and when you find out then the final thing you’ll learn is How To Stop Squeaking Brakes On a Car, so that you can totally eliminate the noise completely.

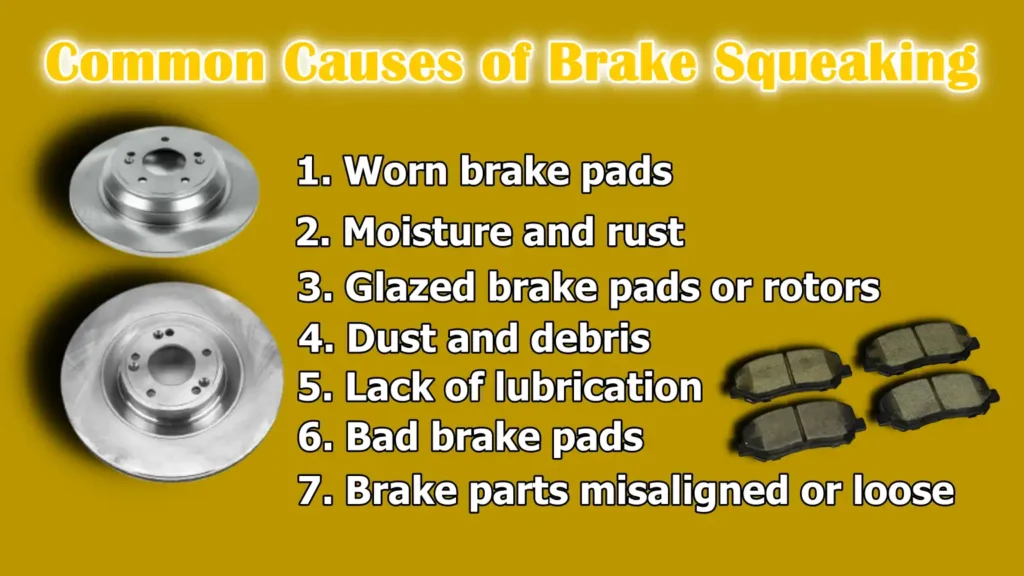

Common Causes of Brake Squeaking

1. Worn brake pads

Brake pads are designed to wear down over time – this is normal. But when they get too thin, a small metal tab (called a wear indicator) on the inside of the pad starts to rub against the rotor, causing a squeaking or creaking sound.

This is actually a built-in safety feature that tells you it’s time to replace your pads. If left unattended, the pads can wear down completely, causing metal-to-metal contact, which not only causes a loud squeaking sound – but can also seriously damage the rotors and increase your stopping distance, making driving unsafe.

2. Moisture and rust

If your car is parked overnight – specially in humid or rainy weather – a thin layer of surface rust can form on the brake rotors. This is completely normal.

The squeaking sound you hear while driving in the morning is probably caused by light rust wearing away at the brake pads.

In most cases, this sound disappears after a few stops. But if your car hasn’t been driven for several days or weeks, rust can develop and affect braking performance unless it’s cleaned or sanded away.

3. Glazed brake pads or rotors

Glazing occurs when your brakes get too hot—often from repeated hard braking, driving downhill or towing heavy loads. When this happens, the surface of the pad or rotor becomes smooth and shiny (glazed), which reduces friction.

This not only causes squeaking, but also reduces your car’s ability to stop quickly. Glazed brakes can often be felt through the pedal, making it feel less responsive or “spongy.” In many cases, replacing the pads and rebuilding the rotor surface is the best solution.

4. Dust and debris

Brake systems are exposed to the outside elements, which means dust, sand, brake dust and small debris can get trapped between the brake pads and rotors.

These small particles can cause a loud squealing or grinding noise when you apply the brakes. While this doesn’t always mean something is broken, over time they can cause uneven wear.

Cleaning your brake components with a brake cleaner spray can help remove deposits and stop the noise.

5. Lack of lubrication

Brakes have moving parts, such as caliper guide pins and metal clips, that need proper lubrication to work quietly and smoothly. If these parts dry out or rust, the pads can stick or wear against the rotor, causing a squeaking or groaning noise.

Using high-temperature brake grease during brake servicing helps prevent this problem. It’s important to never apply lubricant to the friction surface of the pad – only to the contact points where the pad touches the caliper or bracket.

6. Bad brake pads

Cheap or poorly made brake pads are often made of hard materials or low-grade metal shavings, making them more likely to squeak, specially when they’re new.

They also wear out faster and create more brake dust. Investing in high-quality ceramic or semi-metallic pads can not only reduce noise, but also improve braking performance and last longer, making them more economical in the long run.

7. Brake parts misaligned or loose

If any part of the brake system is misaligned or loose – such as the calipers, pads or anti-rattle clips – they can vibrate and produce a squeaking or rattling sound when you brake. This is common after braking if the hardware has not been reinstalled correctly.

In some cases, even a slight misalignment can cause the noise. It is important to ensure that all parts are tightened to the correct torque standards and fitted correctly during installation or repair.

Safety First: Before You Begin

Working on your car’s brakes may seem simple, but safety should always be your top priority. Brakes are a vital part of your vehicle’s safety system and even a small mistake can cause injury or poor performance on the road.

Before you begin inspecting or repairing brakes, it’s important to take a few important precautions. Here’s what you should do to stay safe and make the job easier and more efficient:

1. Park on level ground and apply the parking brake

Always start by parking your vehicle on a flat, level surface. This prevents your car from rolling while you work. After parking, firmly apply the parking brake (also called the emergency brake).

This locks the rear wheels (in most vehicles) and provides an extra layer of safety. If you’re working on the rear brakes, you may also need to use a transmission lock or wheel chock.

2. Use wheel chocks

Wheel chocks are heavy rubber or metal blocks that are placed behind and in front of the wheels that are not being lifted. Even if your parking brake is on, chocks prevent your car from rolling—specially on a gentle slope. It’s a useful tool that could save your life.

You should apply the chocks to at least one side of the wheel you’re lifting (for example, if working on the front brakes, apply the chocks to the rear wheels).

3. Let the vehicle cool down

If you’ve driven your car recently, brake components—specially rotors and calipers—may be very hot. Trying to touch or remove them immediately after driving could cause serious burns. Let the car cool down for at least 30 to 45 minutes before beginning any work.

This also makes it easier to handle bolts and components without them slipping due to heat.

4. Wear gloves and safety glasses

Brake dust contains tiny particles of metal and asbestos, specially in older vehicles. These can be harmful if they come into contact with your skin or eyes or if they are inhaled.

Always wear mechanic’s gloves to protect your hands from cuts, chemicals, dirt and wear safety glasses to protect your eyes from dust or flying debris.

It’s specially important to wear protective equipment when using brake cleaner spray, as it can cause eye and skin irritation if used without proper safety precautions.

Tools

| Tool / Material | What It Does (Simple Explanation) |

|---|---|

| Jack and Jack Stands | The jack raises the car and the jack stands hold it safely in place while you work. |

| Lug Wrench | This tool helps you loosen and tighten lug nuts (the bolts that hold the wheels in place). |

| Brake Cleaner | A spray that removes dust, grease and dirt from brake parts. It helps keep brakes clean. |

| Wire Brush | Used to clean rust or dirt from metal brake parts such as rotors or calipers. |

| Brake Pad Grease / Anti-Squeal Lubricant | A special grease that is applied to the back of brake pads or moving parts to stop squeaking. |

| Replacement Brake Pads (if needed) | New brake pads replace old, worn-out brake pads. They are what stop the car by applying pressure to the rotor. |

| Socket Set | A set of tools (wrenches and sockets) for removing and tightening bolts during brake repairs. |

| Torque Wrench | A tool that helps you tighten bolts just right – not too loose and not too tight. |

| C-Clamp or Brake Caliper Tool | This helps you push the brake caliper piston back in, so the new pads can fit properly. |

How To Stop Squeaking Brakes On a Car – Step-By-Step Guide

If your brakes are squeaking, it’s likely that one or more of the components in your braking system needs cleaning, lubrication, adjustment or replacement.

This step-by-step guide will show you every step you need to take to identify the root cause and fix it effectively—even if you’re not a professional mechanic. These steps use basic tools and parts and focus on keeping your car safe, quiet and in good working order.

1. Inspect the Brake Pads

Start by checking the thickness and condition of the brake pads. Most pads should be replaced when they have worn about 3 millimeters (mm) or less. Pay attention to:

- Uneven wear, which can be caused by a stuck caliper.

- Cracks or shine on the pad surface, causing squeaking.

- Exposed metal, which creates a rattling noise or rubbing and means the pad is completely worn out.

Brake pads have a small metal wear indicator that makes a screeching noise when it’s time to replace them. If you see metal contact with the rotor, replace the pad immediately to avoid further damage.

2. Clean Brake Components

Over time, brake parts accumulate brake dust, road grime and small particles which can cause squeaking when they get trapped between the pad and rotor.

- Use a brake cleaner spray to remove dust and grime from the calipers, rotors and pads.

- Clean any surface rust or stubborn debris with a wire brush, specially if your vehicle has been unused for a significant amount of time.

Never use water or household cleaners — only automotive-grade brake cleaners — as brake systems are sensitive and must remain dry and free of residue.

3. Apply Brake Lubricant

Brake components that slip or move need to be properly lubricated to reduce friction, vibration and noise.

- Apply high temperature brake grease to the caliper slide pins, contact points and the back (non-friction side) of the brake pad.

- Never apply grease to the pad friction surface or rotor, as this will make braking ineffective and dangerous.

Lubrication not only prevents squeaking, but also helps the pads move freely, preventing uneven wear and sticking of the calipers.

4. Resurface or Replace Rotors (If Necessary)

If your rotors are making noise or causing vibrations when you brake, they may be warped, shiny, or worn unevenly.

Signs of a damaged rotor include:

- A pulsating brake pedal.

- Visible grooves or cracks on the rotor.

- Mirror-like shine on the rotor (indicating glazing due to excessive heat).

In such cases, you can either:

- Resurface the rotors (a machine smooths the surface).

- Or replace them if they’re too thin or damaged—most rotors have a minimum thickness rating marked on the side.

5. Replace Worn Brake Pads

If the brake pads are worn or damaged, replacing them will almost always eliminate the squeaking.

Steps:

- Remove the wheel to access the caliper and pads.

- Open the caliper and slide it off (don’t let it hang – use a hook or bungee to support it).

- Remove the old pads and inspect the caliper piston and bracket.

- Use a C-clamp or brake caliper tool to gently push the piston back in.

- Install the new pads, apply grease to the contact points and reassemble the caliper.

- Reinstall the wheel and torque the lug nuts properly.

Always replace pads in pairs (both front or both rear) for uniform braking performance.

6. Check for Loose or Missing Hardware

Sometimes the squeaking noise isn’t caused by the brake parts themselves – but rather by loose, missing or rattling hardware.

Read More:

Alternative Ways To Reduce Brake Noise

Even after cleaning and replacing brake parts, some squeaking may occur—specially when new pads are installed or under specific driving conditions.

Fortunately, there are some additional techniques and upgrades available that can help reduce or completely eliminate brake noise. These methods are not only effective, but mechanics and manufacturers often recommend them for long-term performance and noise control.

1. Installing new brake pads correctly

When you install new brake pads, they must go through a process called “bedding-in” (also known as “breaking in” the brakes). This helps create a smooth, even layer of brake material on the rotor surface and maximizes pad-to-rotor contact.

How to do it:

- Stop slowly several times from speeds between 30 and 40 mph (50–65 km/h) to gradually warm up the brakes.

- Next stop a few times at speeds between 50 and 60 mph (80–95 km/h), without locking the wheels or coming to a complete stop.

- Allow the brakes to cool down by driving for 5-10 minutes without applying hard braking.

This process reduces the chance of glazing, helps eliminate squeaking and improves brake response. One of the most common causes of noise coming from new brakes is improper braking.

2. Upgrading to ceramic or higher-quality brake pads

Not all brake pads are created equal. Cheap or low-quality pads often contain metal fragments, poor bonding agents, or harder materials that create more friction and noise.

Installing ceramic brake pads — or premium semi-metallic pads — can significantly reduce brake squealing. Here’s why:

- The ceramic pads are made of exquisite ceramic materials and copper fibers, which produce less dust and noise.

- They operate quietly, even in extreme temperatures and last longer than organic pads.

- Higher-quality pads also include better noise-cancelling features, such as built-in shims and rubber backing.

Although ceramic pads may cost more upfront, they offer a quieter, cleaner and more durable braking experience, specially for daily drivers.

3. Installing Noise-Reducing Shims

Brake pad shims are thin metal or rubber plates that fit between the brake pad and the caliper piston. Their main function is:

- Reduce vibrations that cause loud squeaks.

- Absorb sound and reduce overall brake noise.

- Provide a smooth braking experience.

If your brake pads don’t come with shims—or the old ones are worn out—installing aftermarket noise-reducing shims is a quick and cost-effective upgrade. Many performance brake pads already have high-quality integrated shims, but if not, universal shims can be added during installation.

When to See a Professional Mechanic

While many brake squeaking can be fixed with simple cleaning, lubrication, or pad replacement, there are times when professional attention is necessary.

Brakes are a vital part of your safety system and ignoring serious problems can lead to costly damage or even accidents. If you notice any of the symptoms below, stop troubleshooting at home and see a trusted ASE-certified mechanic.

1. Persistent squeaking after cleaning or lubrication

If you’ve already cleaned the brake parts, applied the proper lubricant to the contact points and checked for worn pads—yet the squeaking noise persists—it could mean there’s an underlying mechanical problem.

This could include a seized caliper, incorrectly installed hardware, or a warped rotor that needs machine-level resurfacing. Professional mechanics have the diagnostic tools and expertise to accurately identify these problems.

2. Squeaking noises

Unlike squeaking noises, squeaking noises are usually more serious. They often mean that the brake pads have worn down completely and the metal backing is now rubbing directly against the rotor.

This not only causes major damage to your rotors (which may need to be replaced), but also significantly reduces your ability to stop the car safely

Squeaking noises can also be a sign of a foreign object stuck in the brake system or worn brake calipers.

IMPORTANT: Driving with worn brakes can be extremely dangerous and should be avoided. Have the vehicle checked immediately.

3. Brake warning light is flashing

Modern vehicles have warning lights on the dashboard that monitor the brake system. If the brake warning light or ABS light comes on, it could be a sign of:

- Low brake fluid levels.

- A faulty sensor.

- Worn pads on the electronic wear sensor.

- A bad ABS module or master cylinder.

These systems are computer controlled and diagnosing them often requires scan tools, which most DIYers don’t have. In this case, professional service is the best and safest option.

4. Pulsating Brake Pedal

If you feel vibrations or pulsations in the brake pedal when you apply the brakes, it’s usually a sign of warped brake rotors or uneven pad wear.

Warped rotors can be caused by excessive heat, hard braking, or uneven torquing when you apply the wheel. This problem can cause unstable braking and increase your stopping distance.

A mechanic can use precision tools to properly surface the rotors or replace them to bring them to the correct shape.

If ignored, the vibration can get worse and damage other suspension components over time.

Preventive Maintenance Tips

Keeping your brakes quiet, smooth and reliable requires good preventive maintenance. Many brake-related problems – including squeaking noises – can be completely avoided with a few simple habits and regular checkups.

These steps not only extend the life of your braking system; they also save you money, reduce wear on other parts and most importantly, keep you safe on the road. Below are the most effective and easy-to-follow brake maintenance tips every driver should know.

1. Regular Brake Inspection Every 10,000-15,000 Miles

Your brakes are put under a lot of pressure every time you drive and over time, parts like brake pads, rotors and calipers naturally wear out.

Experts recommend having your brakes professionally inspected every 10,000 to 15,000 miles, or at least once a year. During these inspections, mechanics check:

- Pad thickness and wear patterns

- Rotor surface condition

- Caliper speed and alignment

- Brake fluid level and quality

Catching minor problems early — like uneven wear or sticking parts — can prevent major repairs and ensure your brakes stay quiet and responsive.

2. Avoid hard or sudden braking

Pressing your brakes hard or repeatedly applying too much force can generate excessive heat. This heat can cause:

- Glazing on brake pads and rotors, making them more likely to squeak.

- Wrinkled rotors.

- Rapid pad wear and reduced stopping ability.

Instead, practice braking gently and slowly, specially when approaching traffic lights, stop signs or curves. This not only reduces noise and wear, but also improves fuel efficiency and tire life.

3. Clean the brakes during regular car washes

Most people clean the exterior of their car regularly, but forget about the brakes. Dust, dirt, salt and small particles can build up on rotors and calipers, causing them to creak and rust over time. To avoid this:

- Spray your wheels and brake parts with water when you wash your car.

- Every few months, use a brake cleaner spray to remove brake dust and grime, specially if you hear squeaking noises.

A clean brake system performs better, lasts longer and is less noisy.

4. Use OEM or high-quality aftermarket brake parts

One of the most common causes of brake squeaking is cheap or poor quality brake pads. While these may seem like a budget-friendly option, they often contain inferior materials that wear out quickly and are noisy. To avoid this:

- Choose OEM (original equipment manufacturer) parts that meet your vehicle’s factory standards.

- Or select high-quality aftermarket pads made by trusted brands that have noise-cancelling features like shims and rubber coatings.

Better materials mean less squeaking, better heat resistance and longer-lasting performance that actually makes them a smart investment.

Conclusion – How To Stop Squeaking Brakes On a Car

So, by now you have clearly understand that to fix the irritating noise of your brake doesn’t actually requires a lot of tools, but sometimes just an attention can eliminate it as well.

Now, also experiment shows that in drum brakes, adding damping such as: shims or absorbing materials to the brake shoes that experiment shown that it cut squeal incidence from over 60^ down toward zero, which reveals a cost-effective anti-noise solution as well.[¹]

Whether it’s worn brake pads, accumulated dust, lack of lubrication, or poor quality parts, each cause can be diagnosed and resolved with the right tools, knowledge and regular maintenance. By learning how to properly inspect, clean and service your brakes, you’re not just reducing noise – you’re also taking control of your vehicle’s safety and performance.

It’s important to remember that brake noise is never “normal,” even if it persists or worsens. This squeaking, squeaking, or grinding is your car’s way of warning you before major problems arise. Ignoring these noises can lead to costly repairs, longer stopping distances and reduced road safety – all of which can easily be prevented by taking timely action.

By using high-quality parts, following recommended maintenance intervals and using simple techniques like brake lubrication and bedding-in, you can eliminate brake noise before it starts. Plus, knowing when to call a professional mechanic—like when you hear a screeching noise or feel the pedal pulsate—can be the difference between a quick fix and a major repair.

Now, if you have questions in mind then just go to the comment section and let us know clearly what is actually bothering you.

Frequently Asked Questions

Q1. Can I spray WD-40 on my brakes to stop them squeaking?

Answer: No, you should never spray WD-40 or any household lubricant on your brakes to stop squeaking. WD-40 is not designed for high temperatures or friction-heavy parts, such as brake components. In fact, spraying WD-40 on brake pads or rotors can make them slippery, reducing your car’s stopping ability and making driving extremely dangerous. WD-40 may temporarily reduce squeaking, but it will also deposit a layer on the brake surface, making it harder for the pads to grip the rotor. This can increase your stopping distance and even lead to brake failure. Instead of using WD-40, it is better to clean your brake parts with a special brake cleaner spray that is specifically designed to remove dust, grease and grime without affecting braking performance. If brake noise is a common problem, it is best to check the wear of the pads, the cleanliness of the rotors, the lubrication of the caliper pins and whether any parts need to be replaced. Using the right tools and products will help fix the noise safely without risking your vehicle’s braking ability.

Q2. Is it safe to drive with brake noise?

Answer: This depends on what is causing the brake noise. In some cases, it may not be dangerous, but in some situations, it can be a sign of a serious problem. For example, if your brakes make a slight squeaking noise in the morning or after rain, it could be due to mild surface rust or moisture that usually resolves after a few stops. This kind of noise is common and usually not dangerous. However, if the noise continues while driving, specially when you press the brake pedal, it could mean that the brake pads are worn or their components are not properly lubricated or aligned. In worse cases, if you hear a loud squealing noise, it often means that your pads are completely worn out and metal is rubbing against metal – which is very unsafe. Driving with squeaking brakes for a long time can lead to more damage, increased repair costs and poor braking performance. So even if your car stops normally, if you hear a persistent squealing noise, it’s always a good idea to have your brakes checked by a mechanic or inspect them yourself. This way, you can fix the problem before it becomes dangerous or costly.

References:

[1] Friction Induced Noise in Drum Brakes: Finite-Element Modeling and Experiments, Archive of Applied Mechanics (2022). DOI: 10.1007/s00419-022-02189-z

https://link.springer.com/article/10.1007/s00419-022-02189-z

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.