Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

Car Relays actually controls many important functions in your car such as: The Starter Motor, Fuel Pump, Headlights, Air Conditioning and Cooling Fans as well.

Yes, there’s not doubt about being a powerful electrical switches despite of their tiny size, so basically a faulty relay can also cause the big problems such as: car is not starting, flickering lights or malfunctioning of accessories.

That’s why it becomes really important to test the relays so that you can diagnose the electrical issues as it does helps you to find the exact problem without replacing the parts blindly.

Also, you can test relays with simple tools such as: multimeter, a test light or even just swapping with a known working relay, by these methods you can quickly determine whether a relay is functioning properly or not.

Now, this guide is specifically focuses on How to Test Car Relays, as in this guide you’ll learn easy and practical methods so that you can solve your car’s electrical problems.

At First, Let’s Understand About Car Relays

Car relays are small but crucial components in a vehicle’s electrical system.

They act like switches that allow low-current circuits to control high-current circuits.

This means that instead of the high current flowing through dashboard switches or controls, the relay safely routes high current to components like the starter motor, fuel pump, or cooling fan.

Relays protect sensitive electronic components in the car and ensure the electrical system runs efficiently.

It’s important to know about car relays because a faulty relay can cause a variety of problems, from minor electrical malfunctions to the car not starting at all.

1. Basic Construction and Function of a Relay

A typical car relay consists of a coil, an armature, a spring and one or more sets of contacts.

When electricity flows through the coil, it creates a magnetic field that pulls the armature, closing or opening the contacts and completing the circuit.

This simple mechanism allows a small electrical signal to safely control a very large electrical load.

Relays are designed to handle high currents without overheating or damaging the control switch.

Understanding how this structure works helps identify relay malfunctions and also explains why testing them is important to keep your car running properly.

2. Common Types of Relays in Cars

Cars use different types of relays for different functions.

The starter relay is responsible for sending power to the starter motor, which causes the engine to crank.

The fuel pump relay controls the flow of power to the fuel pump, ensuring the engine receives constant fuel.

The air conditioning relay manages the power supply to the AC compressor and fans, enabling climate control.

Other relays may operate lights, cooling fans, or electrical appliances.

Each relay has a specific role and a malfunction in any one of them can cause serious problems, so it’s crucial to identify and test the correct relay for the problem.

3. Symptoms of a Bad Relay

A bad relay can manifest itself in a variety of ways, depending on its function.

Common signs include the car not starting despite a charged battery, flickering or non-functioning headlights, the fuel pump running intermittently, or the air conditioning suddenly stopping.

Sometimes the relay may make a clicking sound, indicating that it’s trying to work, but the component it controls isn’t.

Sometimes, the relay may become stuck in the closed or open position, causing electrical components to cycle on and off.

Recognizing these symptoms early allows you to test the relay and avoid more serious damage or unnecessary replacement of other parts.

Tools

| Description | Why it’s important | |

|---|---|---|

| Multimeter | Used to measure voltage, resistance and continuity in relays and circuits. | Helps determine if a relay is functioning correctly by checking electrical signals. |

| Test light | A simple device that illuminates when current flows through a circuit. | Quickly checks if power is reaching the relay or connected components. |

| Jumper wires | Wires used to temporarily connect circuits for testing. | Allows you to activate the relay or safely check connections without permanent modifications. |

| Protective gloves | Insulated gloves to protect your hands from electrical shock. | Ensures safety when working with live circuits or battery terminals. |

| Disconnect Battery If Necessary | Remove or disconnect the negative terminal of the battery before testing. | Prevents accidental short circuits, sparks, or damage to the car’s electronic components. |

| Avoid Short Circuits | Ensure wires do not touch each other or metal parts during testing. | Protects you and your vehicle from electrical hazards and potential damage. |

| Work in a Well-Lit Area | Ensure you can clearly see wires and connections. | Reduces mistakes and makes testing easier and safer. |

| Follow Manufacturer’s Instructions | Refer to the car manual for relay locations and specifications. | Ensures correct testing procedures and prevents mistakes that could damage the car. |

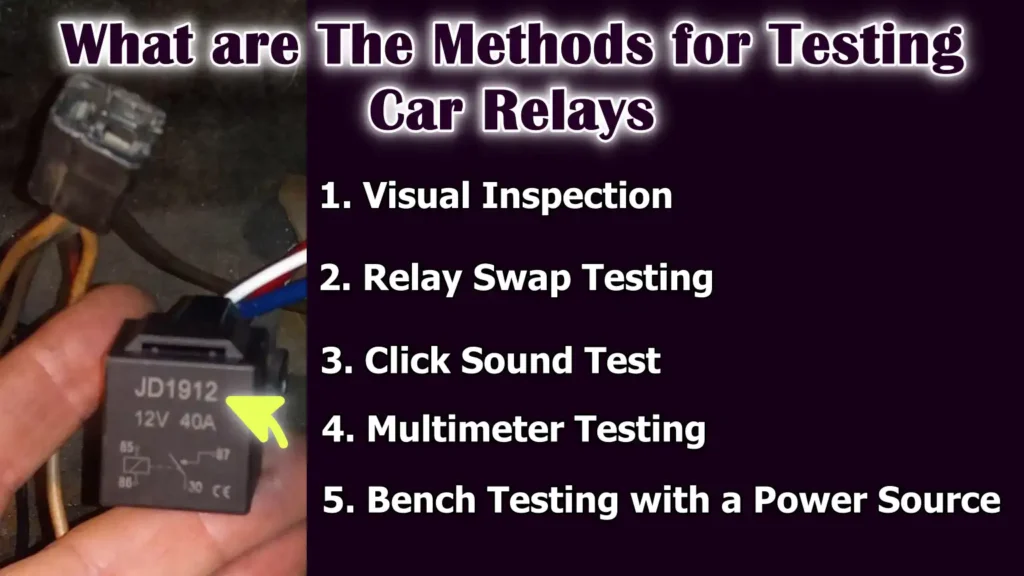

What are The Methods for Testing Car Relays

Testing car relays is essential for accurately identifying electrical problems and preventing unnecessary replacement of parts.

There are several reliable methods for testing relays, suitable for different experience levels and available equipment.

Understanding these methods allows anyone, even beginners, to safely and effectively diagnose relay problems.

1. Visual Inspection

The first step in testing a relay is a careful visual inspection.

Look for a burning smell, corrosion on the terminals, or any signs of damage to the relay casing.

A burning smell may indicate that the relay has overheated due to excessive current, while corrosion may interfere with proper electrical contact.

Physical damage, such as cracks or melted plastic, is a clear sign that the relay is defective and should be replaced.

Visual inspection is a simple and quick way to detect obvious problems before beginning electrical testing.

2. Relay Swap Testing

Another practical method is a relay swap test.

This involves replacing the suspected faulty relay with another identical relay from the fuse box that controls a non-essential function.

If the problem resolves after replacing the relay, it confirms that the original relay was faulty.

This method is effective because it uses existing car parts and requires no special equipment.

It’s a quick way to identify relay problems without performing extensive electrical measurements.

3. Click Sound Test

The click sound test is a basic way to check if a relay is working.

When power is applied to the relay, a distinctive clicking sound should be heard as the internal contacts move.

If no clicking sound is heard, the relay may have a broken coil or stuck contacts.

Sometimes a clicking sound is heard, but the relay still cannot pass current, indicating partial damage.

Listening carefully for this sound while turning on the relay can quickly determine if it is working properly.

4. Multimeter Testing

Multimeter testing provides more accurate information about the relay’s condition.

First, perform a continuity test across the relay coil and switch terminals to ensure that the electrical paths are complete.

Next, check the coil’s resistance, which should be within the manufacturer’s specified range, typically a few tens of ohms.

Finally, measure the voltage across the relay when it is powered to confirm that power is flowing correctly to the switch.

A multimeter can be used for accurate diagnosis and to detect problems that may not be apparent from visual or click tests.

5. Bench Testing with a Power Source

Bench testing with a separate power source is a highly effective way to check the relay’s functionality.

Apply 12 volts directly to the coil terminals and listen for clicking sounds, as well as checking for continuity at the switch end.

This test simulates actual operating conditions without having to install the relay in a car.

It is specially useful for confirming whether the relay will operate correctly under load and provides a complete assessment of its performance.

How to Interpret Test Results

Understanding relay test results is important to determine if a relay is working properly or needs to be replaced.

Accurate interpretation ensures that you avoid unnecessary parts replacement and can effectively troubleshoot electrical problems in your car.

1. What Normal Results Look Like

A properly functioning relay shows specific results depending on the test method used.

When using a multimeter, the resistance of the relay coil should be within the range specified by the manufacturer, typically between 50 and 120 ohms for most automotive relays.

Continuity testing at the switch terminals should show a full path when the relay is activated and an open path when it is inactive.

During the click sound test, a healthy relay produces a clear, distinct clicking sound when voltage is applied to the coil, indicating that the internal contacts are functioning correctly.

Looking at these normal results confirms that the relay is working as expected and is able to safely control the electrical component it manages.

2. Signs of a Bad Relay

A bad relay can give several obvious signs.

If the multimeter shows an open circuit or infinite resistance in the coil, this is a sign of a broken coil or a fault in the internal wiring.

No clicking sound when turned on indicates that the armature or contacts are stuck or damaged.

In some cases, the relay may click, but the switch terminals still cannot pass current, indicating bad or burned contacts inside the relay.

Recognizing these signs can help you quickly identify and replace bad relays before they cause more serious electrical problems in your vehicle.

Read More:

What to Do If a Relay Malfunctions

Once a relay malfunction is detected, taking the right steps ensures that the electrical system works reliably and prevents further damage to your car.

Knowing when to replace or clean a relay, what type of replacement to use and checking the associated circuits can save time, money and unnecessary repairs.

Also, the laboratory study on the high-temperature reliability testing of automotive relays shows that relays actually fail if there’s constantly high temperature, as this test setups shows that it can reproduce the contact degradation and that’s why the heat-related relay failure could be due to the overheated engine bays, so check whenever your engine overheat for any possible relay problem.[¹]

1. When to Replace vs When to Clean Contacts

Some relay malfunctions can be fixed by cleaning the contacts inside the relay if they are slightly rusted or dirty.

However, if the contacts are burned, the coil is damaged, or the relay casing is physically broken, cleaning will not restore proper function.

In such cases, the relay must be replaced.

Knowing the difference between a cleanable problem and a complete replacement ensures that you can effectively resolve the problem without risking a repeat malfunction.

2. Using OEM Relays vs Aftermarket Relays

When replacing a relay, it is usually advisable to use an OEM (original equipment manufacturer) relay because it meets the exact specifications and quality standards of the vehicle.

Aftermarket relays may sometimes work, but may have slightly different ratings or reduced durability, leading to premature failure.

Selecting the right type of relay ensures that the electrical component it controls continues to function reliably over time.

3. If the relay continues to fail repeatedly, check the associated circuits

If the relay continues to fail after replacement, the root problem may not be in the relay, but in the associated circuits.

Overloaded circuits, damaged wiring, or faulty connected components can cause repeated relay failures.

Inspection and repair of these associated circuits is necessary to prevent recurring problems and ensure that the overall electrical system functions safely and efficiently.

Conclusion – How to Test Car Relays

In short, you should not overlook the relays, yes it is true that these are just the small looking switches but they quietly controls essential systems, which is why you should test them first so that you can prevent major problems easily.

Relays, despite their small size, control many vital electrical components, such as starter motors, fuel pumps, air conditioning and headlights.

By learning to visually inspect relays, perform wiggle and click tests, use a multimeter, or bench test them, you can accurately identify faulty relays before they cause serious problems.

Understanding typical test results and recognizing the signs of a faulty relay enables you to take the right steps, whether cleaning the contacts, replacing the relay, or checking the associated circuits.

Using the correct type of relay, preferably OEM, ensures long-term performance and prevents recurring malfunctions.

Regularly testing and maintaining car relays saves time, reduces repair costs and gives you confidence that your vehicle’s electrical system is operating safely and efficiently.

With these methods and precautions, even beginners can effectively troubleshoot relay problems at home.

Do you want to ask something, then comment section is open for you.

Frequently Asked Questions

Q1. What is a car relay and why is it important?

Answer: A car relay is an electrical switch that converts high current to low current in a vehicle’s electrical system. This is important because it helps control vital components like the starter motor, fuel pump, headlights and air conditioning without overloading them. A faulty relay can cause serious problems, such as the car not starting or sudden failure of components. Checking the relay ensures that these components function safely and reliably.

Q2. How can I tell if a relay is faulty?

Answer: Symptoms of a faulty relay include the car not starting even when the battery is fully charged, lights blinking or not working, the fuel pump or AC running intermittently, or strange noises when using electrical components. In some cases, the relay may make a clicking sound, but the connected component still doesn’t work. Using proper testing methods like a multimeter or a relay swap can confirm whether the relay is faulty.

Q3. What tools do I need to test a car relay?

Answer: To test a relay, you need a multimeter to measure voltage, resistance and continuity; a test light to check if current is reaching the relay; jumper wires for temporary connections; and protective gloves to avoid electric shock. These tools allow you to perform safe and accurate testing without damaging the relay or the vehicle’s electrical system.

Q4. Can I test a relay at home without professional help?

Answer: Yes, relays can be tested at home with basic tools and a little knowledge of the car’s electrical system. Simple methods such as visual inspection, listening for clicking sounds, or replacing the relay with another identical relay can quickly determine if the relay is working. For more accurate results, using a multimeter or performing a bench test with a power source can safely and effectively confirm the relay’s condition.

Q5. Should I clean the relay or replace it if it’s bad?

Answer: If the relay contacts are slightly dirty or corroded, cleaning them may restore their operation. However, if the contacts are burned, the coil is damaged, or the relay casing is cracked, they must be replaced. Using high-quality relays, preferably OEM parts, ensures proper operation and longevity. If a relay repeatedly malfunctions, always inspect the associated circuit, as the underlying problem may be in the wiring or connected components.

Q6. What is the difference between OEM and aftermarket relays?

Answer: OEM relays are made by your car’s original manufacturer and match the vehicle’s exact specifications. They provide reliable performance and durability. Aftermarket relays are made by third-party companies and may vary in quality, voltage, or current ratings. Although some aftermarket relays work well, OEM relays are generally recommended to ensure safe and continuous operation.

Q7. Can a bad relay damage other car parts?

Answer: Yes, a faulty relay can affect the components it controls. For example, if the fuel pump relay fails, the engine may not receive fuel, causing engine stalling or starting problems. If the cooling fan relay fails, the engine may overheat. Promptly inspecting and replacing a faulty relay prevents damage to other components and avoids more expensive repairs.

Q8. How often should car relays be tested?

Answer: Car relays don’t have a set lifespan, but be sure to test them whenever you notice any electrical problems, such as not starting, blinking lights, or malfunctioning accessories. It’s also wise to check the relay during routine maintenance, specially in older vehicles or cars with high mileage, to avoid unexpected malfunctions.

References:

[1] Study on the reliability test and failure analysis of automotive relays at high temperature

https://www.researchgate.net/publication/261482695_Study_on_the_reliability_test_and_failure_analysis_of_automotive_relays_at_high_temperature

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.