Written By: Don Dodi

Fact Checked By: Kristen Brown

Reviewed By: Diego Rosenberg

If your convertible top soaks rain water into the fabric, instead of providing protection to expensive interior, so it is the right time to do waterproofing of a convertible top.

Even though, a convertible top is actually designed to resist the water, but it is not actually the permanently waterproof.

As well as, most of the convertible tops are made from the fabric, canvas or vinyl, because of this these kinds of materials slowly lose their protective coating due to the sunlight, rain, dust, air pollution and regular washing as well.

Plus, there’s studies on automotive textiles that shows that the constant UV exposure actually breaks down water-repellent fibers, while the moisture and dirt clog the fabric’s surface, so it allows the water to soak through instead of rolling off.

So, whenever the rain leaks into the cabin, causing mold and mildew, weaken the stitches and even if it damaged interior electronics, then you actually need to learn How to Waterproof a Convertible Top so that you can maintain color, reduce fabric wear and literally extend the life of the roof by many years.

Now, Let’s Understand About a Convertible Top Materials

1. Fabric and Canvas Convertible Tops

Fabric and canvas convertible tops are the most common types used in modern convertible cars.

These tops are typically made from tightly woven materials such as acrylic fabric or cotton-based canvas, which are both breathable and water-resistant.

When new, these materials have a factory-applied water-repellent coating that causes rainwater to bead up and run off the surface.

However, fabric and canvas are naturally porous, meaning that once this protective layer wears off, they can gradually absorb moisture.

Sunlight, air pollution, dust and repeated washing gradually degrade the water-repellent coating, allowing water to penetrate through the small gaps in the fibers.

Because of this, fabric and canvas tops require regular cleaning and re-waterproofing to maintain their effectiveness and prevent leaks, mildew and fabric deterioration.

2. Vinyl and Synthetic Convertible Tops

Vinyl and synthetic convertible tops are made from plastic-based materials that are naturally more water-resistant than fabric.

These tops do not absorb water like fabric because the surface is solid, not woven.

When the material is in good condition, water typically remains on the surface and runs off easily.

However, vinyl tops can also lose their protection over time due to heat, UV rays and harsh cleaning chemicals.

As vinyl ages, it can dry out, crack, or become brittle, allowing water to penetrate through seams and weak points.

Vinyl and synthetic tops require different care products that focus on conditioning the surface and maintaining flexibility rather than soaking into the fibers.

3. Differences in Water Absorption and Care Needs

The biggest difference between fabric-based tops and vinyl tops is how they handle water.

Fabric and canvas tops rely on a water-repellent coating to prevent water from penetrating, while vinyl tops rely on the material itself to keep moisture out.

If fabric tops are not properly protected, they can absorb water, leading to mildew and mold problems.

Vinyl tops generally repel water better, but if neglected, the surface can deteriorate.

Because of these differences, fabric tops require deep cleaning to remove dirt trapped in the fibers before waterproofing, while vinyl tops require gentle cleaning and conditioning to prevent cracking and surface damage.

Using the wrong cleaning or waterproofing method can reduce effectiveness and shorten the lifespan of the top.

4. Why the Material Type Matters Before Applying Waterproofing Products

Knowing the correct material of your convertible top is crucial before applying any waterproofing product.

Waterproofing sprays designed for fabric are formulated to soak into the woven fibers and create an invisible protective layer, while vinyl protectants are designed to coat and condition the surface.

Applying a fabric waterproofing product to a vinyl top will not adhere properly and may leave residue or streaks.

Similarly, using a vinyl-based product on fabric can restrict airflow and trap moisture within the fibers.

Combining waterproofing products with the right materials provides superior water resistance, long-lasting protection and prevents damage to convertible tops.

This simple step can save you money, prevent leaks and significantly extend the lifespan of your roof.

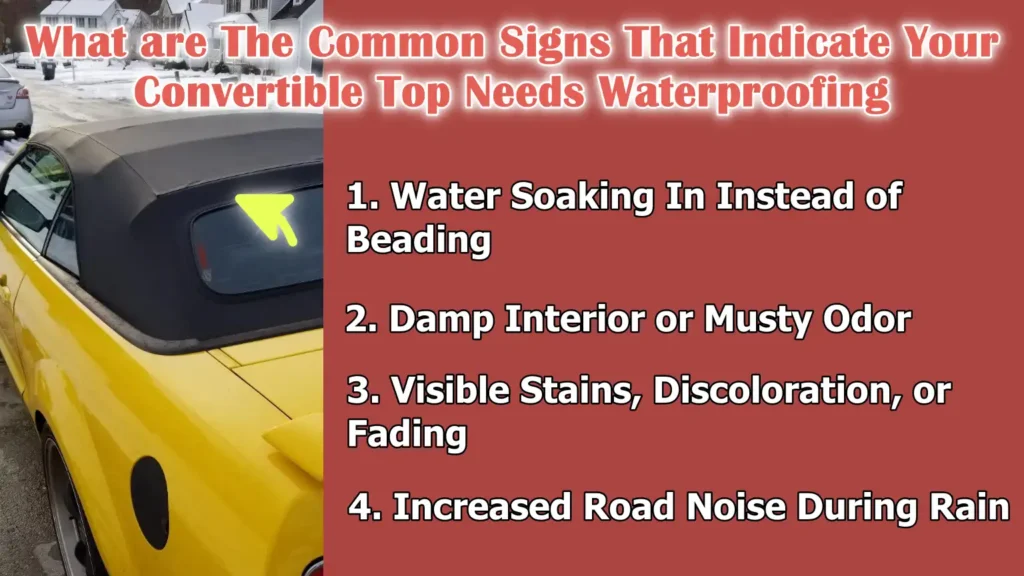

What are The Common Signs That Indicate Your Convertible Top Needs Waterproofing

1. Water Soaking In Instead of Beading

The clearest sign that your convertible top needs waterproofing is when rainwater doesn’t bead up on the surface.

On a good, protected convertible top, water stays on the surface and quickly runs off.

When the waterproofing layer deteriorates, water begins to soak into the fabric instead of staying on the surface.

This happens because the tiny fibers in the top open up and absorb moisture.

Over time, this absorption process can weaken the material, stretch the fabric and eventually allow water to seep into the cabin.

If you notice dark, wet patches after rain or washing, it means the protective coating has failed and waterproofing is needed.

2. Damp Interior or Musty Odor

A damp or musty smell inside the car is often caused by moisture seeping through the convertible top.

Even small amounts of water can get trapped in the headliner, carpets, or seats.

When moisture remains inside the car, it creates the perfect environment for mold and mildew to grow.

These odors usually precede visible leaks.

In many cases, the convertible top looks fine from the outside, but water is slowly seeping through the fabric or seams.

Waterproofing helps seal the top and prevent moisture from entering, protecting the interior from long-term damage and unpleasant odors.

3. Visible Stains, Discoloration, or Fading

Stains, uneven coloring, or discolored areas on a convertible top often indicate that the protective layer has broken down.

Sunlight breaks down the outer coating, while dirt and pollution become deeply embedded in the material.

Once the surface protection wears off, the fabric becomes more susceptible to water, stains and fading.

Discoloration also indicates that the material is deteriorating and losing its strength.

Applying waterproofing after proper cleaning helps restore the protective barrier, minimizing further fading and slowing down damage to the fabric caused by UV rays and moisture.

4. Increased Road Noise During Rain

Increased road or rain noise while driving can also be a sign that your convertible top needs waterproofing.

When the fabric absorbs water, it becomes heavier and less flexible.

This causes the top to react differently to wind and rain, allowing more noise to penetrate.

Waterlogged material can also compromise the roof’s tight seal, allowing outside noise to easily enter the cabin.

Proper waterproofing helps keep the fabric dry, lightweight and strong, providing better insulation and resulting in a quieter and more comfortable driving experience.

Tools

| Tool or Material | What It Is | Why It Is Needed |

|---|---|---|

| Convertible Top Cleaner | Specially formulated liquid cleaner for fabric or vinyl tops. | This removes dirt, dust, bird droppings and pollution that can prevent the waterproofing from adhering. |

| Soft-Bristle Brush or Microfiber Brush | Soft bristle brush. | It loosens deeply embedded dirt, without tearing or scratching the fabric. |

| Microfiber Towels | Soft, lint-free fabric. | It is used for wiping, drying and safely removing excess cleaner. |

| Convertible Top Waterproofing Spray or Sealant | A protective liquid that repels water. | This restores the water resistance and prevents rainwater from seeping into the surface. |

| Masking Tape and Plastic Sheets | Protective covering material. | It protects the car’s paint, windows and trim from spray stains. |

| Gloves and Eye Protection | Basic equipment for hand and eye protection. | Protects skin and eyes from chemical exposure. |

How to Prepare the Convertible Top

1. Choosing a Shady, Well-Ventilated Area

The convertible top should always be prepared in a shady, open area rather than in direct sunlight.

The sun’s heat can cause cleaners and waterproofing products to dry too quickly, preventing them from spreading evenly and adhering properly to the material.

A well-ventilated area allows moisture and chemical vapors to dissipate, making the process safer and more effective.

Shade also helps maintain a consistent temperature for the top, which is important because excessive heat can cause the fabric to expand and the vinyl to soften, leading to uneven coverage during waterproofing.

2. Checking for Tears or Damage Before Waterproofing

Before beginning any cleaning or waterproofing, the convertible top should be carefully inspected for small tears, worn seams, or loose stitching.

Waterproofing products are designed to protect healthy material, not to repair damage.

Applying waterproofing to torn fabric can trap moisture inside and worsen the damage over time.

Small tears or weak spots are often more visible when the top is wet, so this inspection helps prevent leaks and future repairs.

Addressing any damage beforehand ensures that the waterproofing layer performs as expected and lasts longer.

3. Removing Loose Dirt, Dust and Debris

Loose dirt, dust, leaves and other debris should be removed before applying any cleaner or waterproofing product.

These particles act as a barrier between the convertible top and the product, hindering proper adhesion.

The dirt can also be rubbed into the material during cleaning, potentially causing stains or scratches.

Gently brushing or vacuuming the surface allows the cleaner and waterproofing spray to reach the fabric or vinyl evenly.

This simple step significantly improves the final result and helps prevent damage caused by uneven water penetration.

4. Why is surface preparation essential for product bonding?

Proper preparation is the most crucial factor in successful waterproofing.

Waterproofing products require a clean, dry and stable surface to bond with the material at a microscopic level.

When the surface is dirty, damaged, or too hot, the product cannot form a strong protective layer.

Poor bonding results in reduced water resistance and premature failure.

Good preparation allows the waterproofing material to seal even tiny gaps, helps water droplets bead up and provides long-lasting protection.

Failure to prepare the surface often leads to wasted product and poor performance.

How to Thorough Cleaning of the Convertible Top

1. Applying a Specialized Convertible Top Cleaner

A convertible top should always be cleaned with a cleaner specifically designed for fabric or vinyl roofs.

These cleaners are formulated to remove dirt, bird droppings, tree sap and pollution without damaging the fibers or surface coating.

Regular car shampoos or household cleaners are too harsh and can strip away any remaining water protection.

A specialized convertible top cleaner works by breaking down dirt while remaining gentle on the material.

Applying the cleaner evenly allows it to penetrate the surface where dirt accumulates, which is crucial for restoring proper water resistance.

2. Gently Brushing to Loosen Embedded Dirt

After applying the cleaner, gently brushing helps loosen dirt trapped in the fabric fibers or embedded in the vinyl texture.

Dust and pollution accumulate on convertible tops, settling into small crevices and not easily removed by simply spraying.

Using soft bristles prevents tearing, fraying, or scratching the surface.

Gentle scrubbing loosens the dirt so it can be rinsed away, rather than pushed further into the material.

This step improves the top’s final appearance and helps subsequent waterproofing products adhere evenly.

3. Rinsing Without Over-Wetting the Fabric

Rinsing is necessary to remove the cleaner and loosened dirt, but excessive water can cause problems, specially with fabric tops.

Over-wetting the material allows water to penetrate layers that take a long time to dry.

This trapped moisture can weaken the fabric and promote mildew growth.

Using a gentle stream of water effectively removes dirt while keeping moisture levels under control.

The right cleaning products clean the surface without oversaturating it, which protects the structure of the convertible top.

4. Allow to dry completely before waterproofing

It is crucial to allow the convertible top to dry completely before applying any waterproofing product.

Waterproofing sprays and sealants require a dry surface to adhere properly to the material.

If moisture is present, the product may trap water within the fabric or fail to bond correctly.

This reduces its effectiveness and shortens the lifespan of the protection.

Drying time can vary depending on weather conditions and the type of material.

Allowing sufficient drying time ensures a strong bond, improved water resistance and longer-lasting results.

Read More:

How to Protect the Surrounding Area

1. Covering Paint, Glass and Trim

Before applying any waterproofing product, it’s crucial to protect the car’s paint, windows and exterior trim.

Most convertible top waterproofing sprays are designed to adhere strongly to fabric or vinyl, but if they stray outside the target area, they can leave marks on painted surfaces or glass.

These marks can be difficult to remove once dry.

Covering the surrounding surfaces creates a barrier that prevents unwanted contact and keeps the car clean.

This step also protects rubber seals and plastic trim from chemical buildup that can cause discoloration or hardening over time.

2. Using Masking Tape Around Edges and Seams

Masking tape helps create clean edges where the convertible top meets the car body.

Applying tape around seams, edges and trim lines prevents the waterproofing spray from spreading to unwanted areas.

This is specially important around stitching and seals, where excess product can accumulate and dry unevenly.

Masking tape also helps with even application by clearly defining where to spray and where to stop.

Proper taping results in a better finish and reduces cleanup time after the waterproofing is complete.

3. Preventing Overspray Stains and Residue

Overspray occurs when small droplets of the waterproofing spray travel beyond the surface of the convertible top.

These droplets can land on paint, glass, or plastic and leave hazy stains or sticky residue.

Preventing overspray is important because the residue can attract dirt and make cleaning the surfaces difficult later on.

Proper coverage and careful spraying minimize waste and improve protection.

Preventing overspray ensures that the waterproofing product stays where it is needed most, providing robust protection without damaging surrounding areas.

How to Apply a Waterproofing Products

1. Choosing the Right Waterproofing Spray for Your Top

Choosing the correct waterproofing product is crucial for effective protection.

Convertible tops are made from either fabric-based or vinyl-based materials and each requires a specific type of waterproofing spray.

Fabric sprays are designed to penetrate woven fibers and create an invisible barrier that repels water while allowing air to pass through.

Vinyl products are formulated to coat the surface and maintain flexibility.

Using the wrong product can lead to reduced breathability, decreased water resistance, or visible staining.

Matching the spray to the material ensures strong bonding, long-lasting protection and safe application on the convertible top.

2. Correct Spraying Distance and Technique

Applying waterproofing from the correct distance ensures the product spreads evenly across the surface.

Spraying too close can result in wet spots and uneven coverage, while spraying too far can lead to dry patches where the product doesn’t adhere properly.

A steady, controlled motion ensures even application and prevents oversaturation of the material.

Consistent movement also prevents buildup in one area, which can cause the surface to become stiff or discolored.

The correct technique ensures the waterproofing layer forms uniformly across the entire top.

3. Applying Even, Overlapping Coats

Waterproofing works best when applied in thin, even layers rather than one heavy coat.

Slightly overlapping each pass ensures no areas are missed and the entire surface receives consistent protection.

Thin layers allow the product to properly penetrate or adhere to the material without clogging it.

Allowing a short drying time between coats improves bonding and durability.

This method creates a strong, uniform layer that repels water more effectively and lasts longer.

4. Paying Extra Attention to Seams and Stitching

Seams and stitching are the weakest points of a convertible top because they contain small gaps where water can penetrate.

These areas are constantly subjected to movement and stress, which can weaken the protection over time.

Applying extra waterproofing to the seams helps seal these gaps and prevents leaks during heavy rain.

Carefully covering the areas around the stitching improves overall water resistance and protects the interior from moisture damage.

Paying attention to these areas significantly enhances the effectiveness of the waterproofing process.

How to Perform Cure and Dry Process

1. Suggested Drying Time Between Coats

After applying the first coat of waterproofing, the convertible top needs time to dry before the next coat is applied.

This drying time allows the product to penetrate the material and begin forming a protective layer.

Most waterproofing sprays require at least fifteen to thirty minutes between coats, depending on temperature, humidity and airflow.

If the second coat is applied too soon, the surface may remain damp underneath, leading to weaker bonding and uneven protection.

Allowing adequate drying time between coats ensures that each layer adheres properly and provides superior overall water resistance.

2. Final Curing Time Before Exposure to Rain

Curing is the time required for the waterproofing product to fully bond and harden into a durable water-repellent layer.

Even if the top feels dry to the touch, the waterproofing is still curing at a molecular level.

Most products require several hours to fully cure and some need a full day before being exposed to rain or washing.

Allowing this curing time prevents water from damaging the protective layer before it has fully strengthened.

Exposing the top to rain too soon can reduce effectiveness and shorten the lifespan of the waterproofing.

3. Why Patience Ensures Long-Lasting Water Protection

Patience during the drying and curing process directly impacts how long the waterproofing lasts.

Rushing the process can trap moisture, weaken bonding and create areas where water can penetrate.

When the product is given sufficient time to cure, it forms a stable barrier that repels water, protects the seams and resists wear and tear from the sun and weather.

Taking extra time during this stage results in better performance, fewer leaks and longer-lasting protection.

Proper curing is one of the simplest yet most crucial steps in successful convertible top waterproofing.

How to Test a Waterproofing Effect

1. Light Water Spray Test

Once the waterproofing product has fully dried, a light water spray test helps confirm that the convertible top is properly protected.

This test should be performed with a gentle stream of clean water rather than high pressure.

The light spray mimics natural rainfall and shows how the surface reacts to moisture.

A properly waterproofed top will immediately repel water, while unprotected areas will darken as they absorb water.

This simple test helps confirm that the waterproofing process has worked as expected.

2. Checking for Water Beading and Runoff

Water beading is one of the strongest indicators of successful waterproofing.

When water lands on a protected convertible top, it should form small, round beads that sit on the surface and roll off easily.

This behavior shows that the protective layer is active and preventing moisture from penetrating the material.

Smooth, unabsorbed runoff indicates even coverage across the surface.

If the water spreads out or is slowly absorbed, it means the waterproofing is weak or incomplete in that area.

3. Identifying Missed Spots for Touch-Ups

Testing also helps identify areas that may have been missed during application.

Seams, edges and corners are common areas where water can still penetrate.

These areas may appear darker or remain wet longer than surrounding areas.

Identifying these spots early allows for quick touch-ups before water damage occurs.

Applying a small amount of waterproofing to these missed areas improves overall protection and ensures the entire convertible top is evenly sealed against moisture.

How to Maintain a Waterproofing of a Convertible Top

1. How often should waterproofing be reapplied?

Waterproofing doesn’t last forever and gradually deteriorates due to sun, rain, dust and regular use.

Under most driving conditions, convertible tops should be re-waterproofed every six to twelve months.

Cars that are parked outdoors or frequently driven in the rain may require more frequent treatment.

An easy way to check is to observe how water behaves on the surface.

If water stops beading and starts soaking in, it’s time to reapply the waterproofing.

Regular reapplication maintains the protective layer and prevents long-term damage to the material.

2. Safe Washing Methods for Convertible Tops

Proper washing techniques help maintain the waterproofing of a convertible top.

Gentle cleaning with a specialized convertible top cleaner removes dirt without damaging the protective layer.

Using a soft brush and low water pressure prevents abrasion and damage to the fibers.

Harsh scrubbing or high-pressure water jets can weaken seams and cause premature failure of the waterproofing.

Allowing the top to dry completely after washing also prevents moisture from becoming trapped.

Proper washing extends the life of both the material and the waterproofing treatment.

3. Products and Methods to Avoid

Certain products can damage convertible tops and compromise their water-repellent properties.

Household cleaners, harsh detergents and alcohol-based solutions can degrade the protective coating and dry out the material.

Pressure washers used at close range can force water into the seams and weaken the structure.

Wax products designed for painted surfaces should never be used on fabric tops, as they block airflow and trap moisture.

Avoiding these products ensures flexibility, breathability and long-lasting protection.

4. Seasonal Care Tips

Different seasons affect convertible tops in different ways.

In the summer months, intense sunlight can fade the color and weaken the waterproofing, so parking in the shade minimizes damage.

During the rainy season, regularly checking for water beading ensures that the protection is still effective.

In colder weather, the material can become stiff, making gentle cleaning and conditioning even more important.

Seasonal care helps keep your convertible top protected year-round and prevents premature deterioration.

Basic Common Mistakes You Should Avoid

As well as, there’s research about superhydrophobic textiles and that shows that the durable waterproof fabrics actually retains their water-repelling properties even after the abrasion and contamination of it, so you should select accordingly when you go for waterproofing treatment for convertible tops, as it gets the exposure to the dust, debris and road wear that can degrade the effectiveness of fabric if not chosen right one.[¹]

1. Applying Waterproofing to a Dirty or Wet Roof

Applying waterproofing to a dirty or wet convertible roof is one of the most common mistakes.

Dirt, dust and moisture create a barrier that prevents the waterproofing product from properly adhering to the material.

When waterproofing is applied to a wet surface, moisture can become trapped within the fabric or seams.

This trapped moisture weakens the material and can lead to mold, mildew and unpleasant odors.

A clean and completely dry surface allows the waterproofing to seal correctly and last much longer.

2. Using Household Waterproofing Sprays

Household waterproofing sprays are not designed for automotive convertible roofs.

These products are often formulated for shoes, furniture, or outdoor clothing and may contain harsh chemicals that can damage the car’s roof material.

They can leave stubborn stains, discolor the surface, or block airflow through the fabric roof.

Automotive-grade waterproofing sprays are tested to withstand sun, heat and movement.

Using the correct product ensures safe application, superior water resistance and long-lasting protection.

3. Applying Too Much Product and Clogging the Fabric Pores

Using too much waterproofing product can be just as detrimental as using too little.

A fabric convertible roof needs to remain breathable to allow trapped moisture to escape.

When too much product is applied, it can clog the tiny pores of the fabric and create a stiff surface.

This reduces flexibility and can lead to uneven water resistance.

Thin, even coats allow the product to adhere properly while maintaining breathability.

Correct application improves performance and extends the life of the convertible roof.

4. Ignoring Manufacturer’s Instructions

Every waterproofing product comes with specific instructions based on its chemical composition and intended use.

Ignoring these instructions can reduce effectiveness and lead to damage.

Factors such as drying time, spray distance and curing conditions are carefully designed to ensure proper bonding.

Skipping steps or rushing the process often results in poor outcomes.

Following the manufacturer’s guidelines ensures that the waterproofing performs as expected and provides long-lasting protection.

Know Different Between Professional & DIY Waterproofing

1. When is DIY Waterproofing Sufficient?

DIY waterproofing is typically sufficient for convertible tops that are in good condition and only require routine protection.

When there are no tears in the fabric or vinyl, no loose stitching, or no significant leaks, a good quality automotive waterproofing spray can effectively restore water repellency.

DIY methods work well for regular maintenance and seasonal protection.

With proper cleaning, correct application and sufficient drying time, DIY waterproofing can provide robust water repellency that lasts for several months.

It’s also convenient, allowing car owners to maintain their convertible tops without specialized equipment.

2. Situations Requiring Professional Treatment

When a convertible top shows significant signs of wear or damage, professional waterproofing becomes necessary.

Deep stains, excessive fading, persistent leaks, or weakened seams often require specialized cleaning and sealing techniques.

Professionals use industrial-grade products and tools that can penetrate deeper into the material and provide stronger bonding.

They can also identify structural issues that may not be apparent to the owner.

Professional treatment is recommended for older tops, high-end vehicles, or in cases where water ingress persists despite DIY attempts.

3. Cost Comparison and Durability Differences

DIY waterproofing is generally more cost-effective, with costs limited to cleaning and waterproofing products.

This makes it ideal for routine care and budget-friendly maintenance.

However, DIY protection may require more frequent reapplication, specially in harsh weather conditions.

Professional waterproofing is more expensive, but it typically lasts longer due to the use of stronger products and controlled application techniques.

Professional treatments can offer greater durability and better protection against heavy rain and sun exposure.

Choosing between DIY and professional options depends on the condition of the convertible top, usage habits and long-term maintenance goals.

Conclusion – How to Waterproof a Convertible Top

Basically, most of the convertible roof problems actually begins when the water resistance fades away, not when the fabric actually looks damaged.

Plus, a convertible top is constantly subjected to the stresses of sunlight, moisture, dust and temperature fluctuations, which gradually degrade the factory-applied protection.

When waterproofing is properly applied, it restores the top’s water-repellent properties, strengthens the fabric or vinyl and prevents mildew, leaks and interior damage.

Proper cleaning, careful application and allowing sufficient drying time ensure that the waterproofing product adheres well and lasts longer.

Regular maintenance and timely reapplication extend the life of a convertible top by many years, saving money on expensive repairs or replacements.

By following the correct steps and using the right products, car owners can maintain comfort, appearance and long-term value, ensuring their convertible remains enjoyable in all weather conditions.

Now, you can ask unsolved questions in the comment box below this guide.

Frequently Asked Questions

Q1. What exactly does waterproofing a convertible top do?

Answer: Waterproofing creates a protective layer on the convertible top that helps water bead up on the surface instead of soaking into the material. This layer fills in the tiny gaps in the fabric fibers or seals the vinyl surface, allowing rainwater to bead up and run off. Waterproofing also helps protect against sun damage, dirt buildup and premature wear, making the top more durable and longer-lasting.

Q2. Do convertible tops come waterproofed from the factory?

Answer: Most convertible tops come with a factory-applied water-repellent coating, but this protection is not permanent. It gradually degrades due to sun exposure, rain, pollution and regular washing. Over time, the top may look fine but no longer effectively repel water. This is why re-waterproofing is necessary as part of regular maintenance.

Q3. How do I know if my convertible top needs waterproofing?

Answer: A convertible top typically needs waterproofing when water no longer beads up on the surface and instead begins to soak in. Other signs include a musty smell inside the car, dark wet patches after rain and longer drying times. These indicate that the protective layer has weakened and needs to be restored.

Q4. Can waterproofing fix leaks in a damaged convertible top?

Answer: Waterproofing cannot repair tears, holes, or severely damaged seams. It is designed to protect healthy material, not to fix structural problems. If the top has any visible damage or persistent leaks, these should be repaired first. Applying waterproofing to damaged areas can trap moisture and worsen the problem.

Q5. Is waterproofing safe for fabric convertible tops?

Answer: Yes, waterproofing is safe for fabric convertible tops when the correct product is used. Fabric-safe waterproofing sprays are designed to penetrate the fibers without blocking airflow. This keeps the top breathable while still repelling water. Using the wrong product, such as vinyl or household sprays, can damage the fabric.

Q6. Is waterproofing different for vinyl convertible tops?

Answer: Yes, vinyl tops require different care. Vinyl waterproofing products are designed to coat and condition the surface, not penetrate it. These products help keep the vinyl supple, prevent cracking and repel water. Using fabric waterproofing on vinyl may not work properly and can leave a residue.

Q7. How long does convertible top waterproofing last?

Answer: Under normal conditions, waterproofing typically lasts six to twelve months. Cars that are parked outdoors, frequently driven in the rain, or exposed to harsh sunlight may require more frequent waterproofing. Regular washing and weather exposure will gradually degrade the protective layer over time.

Q8. Can I wash my car after waterproofing the convertible top?

Answer: Yes, but it’s crucial that the waterproofing is completely dry. This usually takes several hours or even a full day, depending on the product. Washing too soon can weaken the protective layer. Once dry, it’s recommended to gently wash the convertible top with a cleaner specifically designed for convertible tops.

Q9. Can I waterproof my convertible top myself at home?

Answer: Yes, most convertible tops can be waterproofed at home with the right products and preparation. DIY waterproofing works well for routine maintenance when the top is in good condition. Thorough cleaning, even application and allowing sufficient drying time are key to success.

Q10. Is professional waterproofing better than DIY?

Answer: Professional waterproofing can offer longer-lasting protection, specially for older or more worn tops. Professionals use stronger products and specialized tools. However, for regular maintenance, DIY waterproofing is usually sufficient and more cost-effective. The best option depends on the condition of the top and the level of protection required.

Q11. Can waterproofing damage the car’s paint or glass?

Answer: Waterproofing sprays can stain or mark paint and glass if they are not protected. Therefore, it’s essential to mask off surrounding areas before application. If applied carefully and any overspray is wiped away immediately, waterproofing will not damage surrounding surfaces.

Q12. How soon can I drive my car after waterproofing my convertible top?

Answer: You can usually drive the car once the surface is dry, but it’s best to avoid rain until the product has fully cured. Driving in the rain too soon can reduce the effectiveness. Waiting the recommended drying time ensures strong and long-lasting water resistance.

References:

[1] A waterproofing textile with robust superhydrophobicity in either air or oil surroundings

https://www.sciencedirect.com/science/article/abs/pii/S187610701630493X

Guys, I’m a car audio enthusiast and customization expert and I love clear sound and clean installation. Plus, I have spent years helping people build their dream audio setups. And whenever I’m working on cars, I probably listen to music and thinks about the next big upgrade.